Product Description

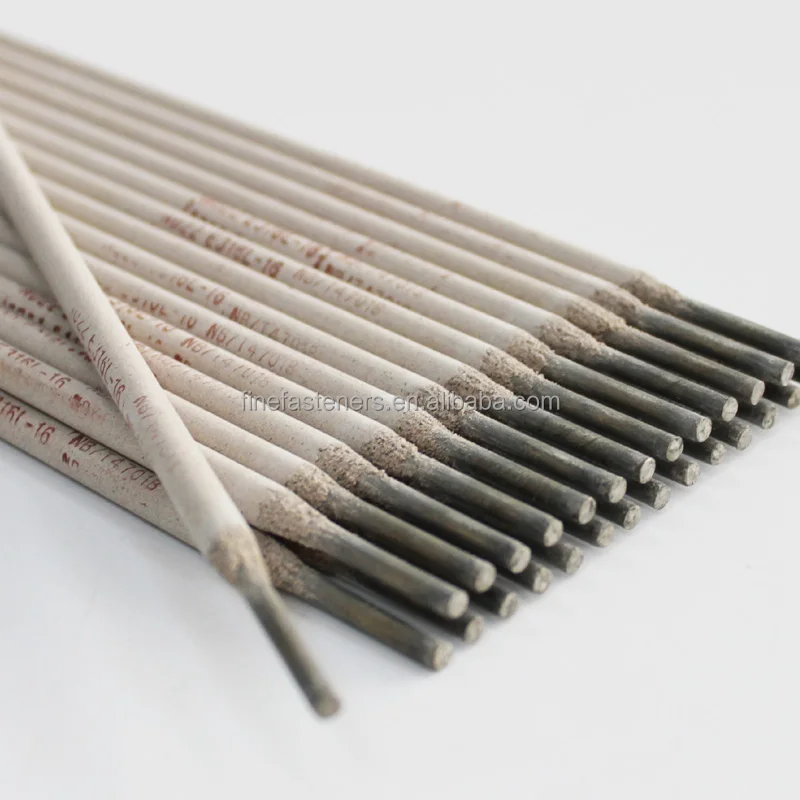

Hunting for top-quality welding electrodes that deliver exemplary performance? Look absolutely no further than FFI Welding Rod Electrode Flux Coated.

FFI Welding Rod Electrode Flux Coated is actually a quality that is premium item that's developed to meet with the needs of both the professional welder as well as the DIY lover. This welding electrode provides uncompromising quality and consistent performance, that makes it the perfect choice for a range of welding applications featuring its high level formulation and revolutionary design.

This welding electrode is very created and manufactured by FFI, a brandname this is certainly leading the welding industry. FFI is recognized because of its dedication to quality, innovation, and customer support, and also this welding electrode isn't any exception.

The FFI Welding Rod Electrode Flux Coated is very built to give a very good and weld this is certainly durable resists breaking and corrosion. Its high level formulation implies that it gives performance this is certainly consistent welding that is many, including mild steel, stainless steel, cast iron, and more.

This welding electrode can also be simple to use, having a arc this is certainly smooth's easy to maintain. Its flux coating helps you to make sure it makes welds which can be exemplary are strong, clean, and free of slag. Sufficient reason for its packaging that is convenient can store and transport, rendering it your choice that is perfect workers on the run.

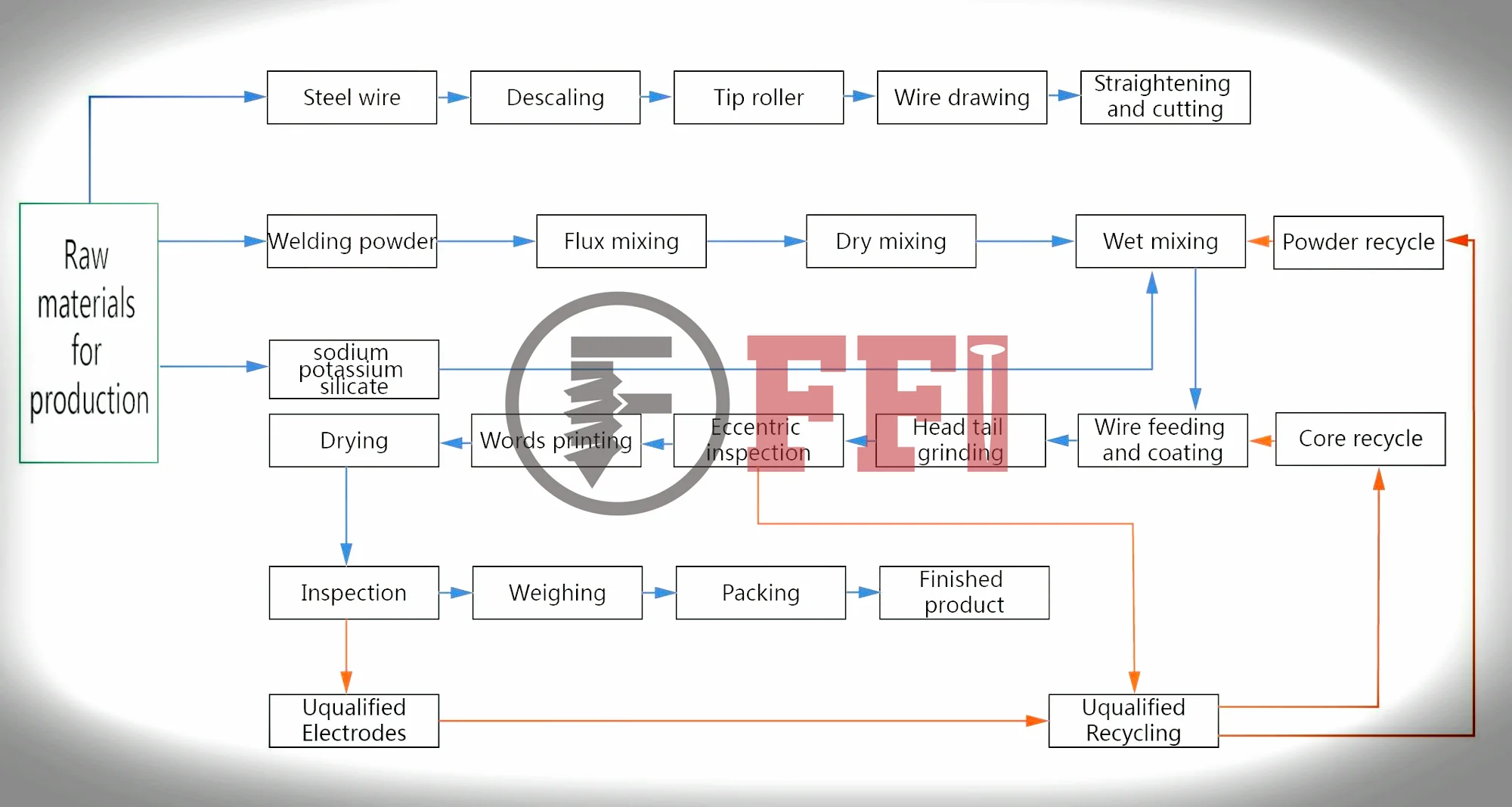

No. |

Equipment |

Function |

1 |

Descaling machine |

Remove the dust from the wire. |

2 |

Tip roller |

Sharpen the tip of wire. |

3 |

Butt-welding machine |

To weld the wire tips when 1 roll is finished. |

4 |

Wire drawing machine |

To draw the wire into diameter needed. |

5 |

Single arm crane |

To lift the wires. |

6 |

Wire cutting machine |

To cut wire into size. |

7 |

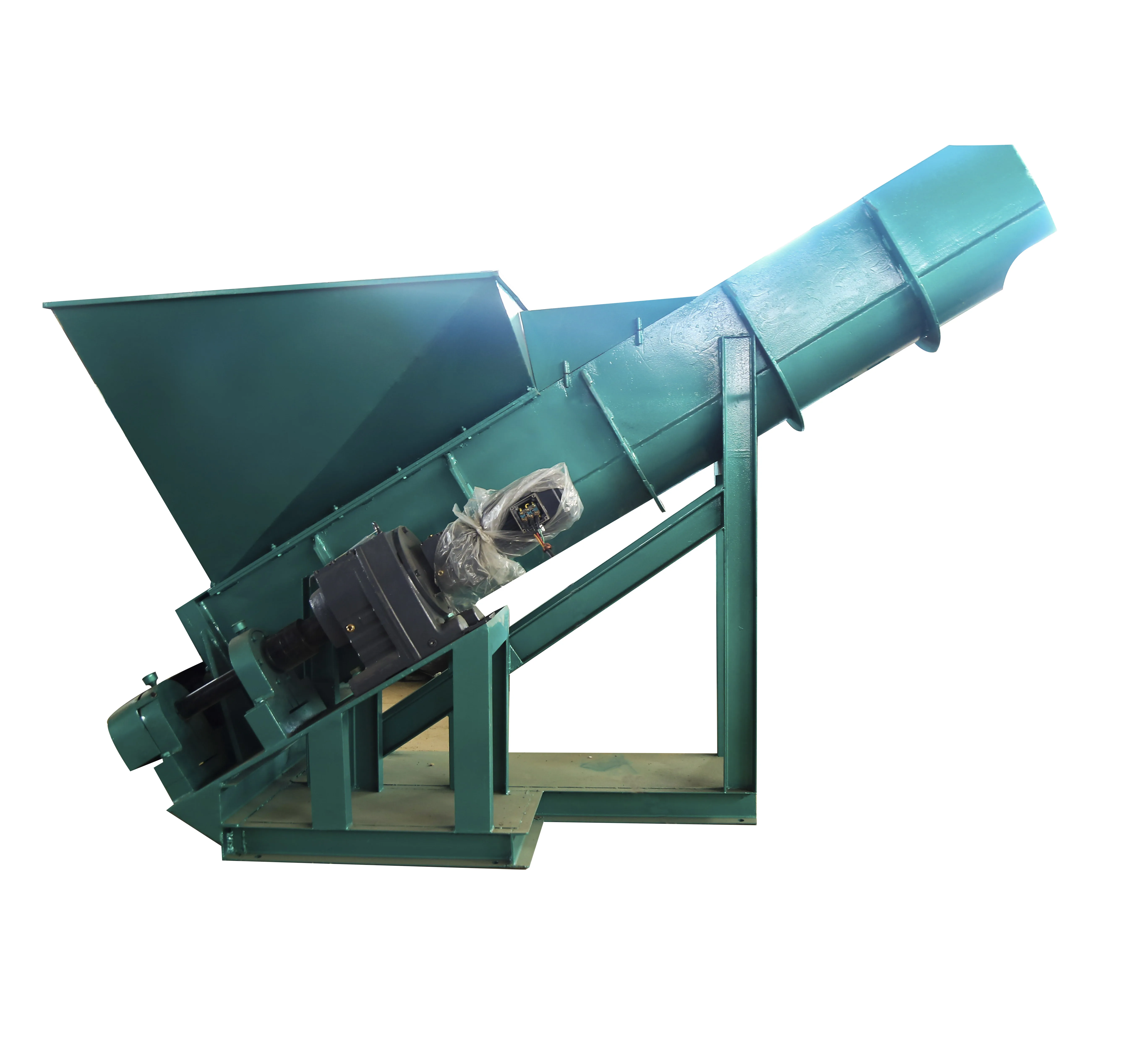

Powder mixer |

Mix the powder for coating. |

8 |

Wire-feed machine |

Wire supply. |

9 |

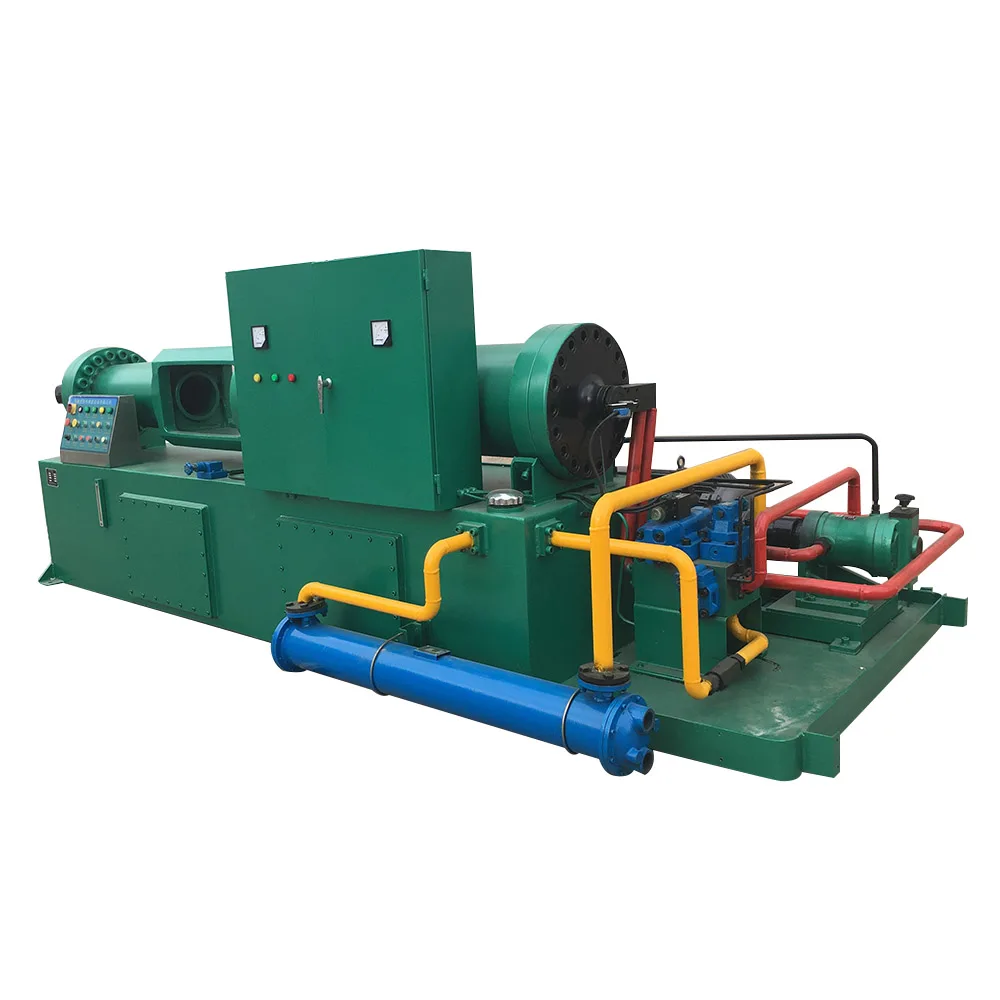

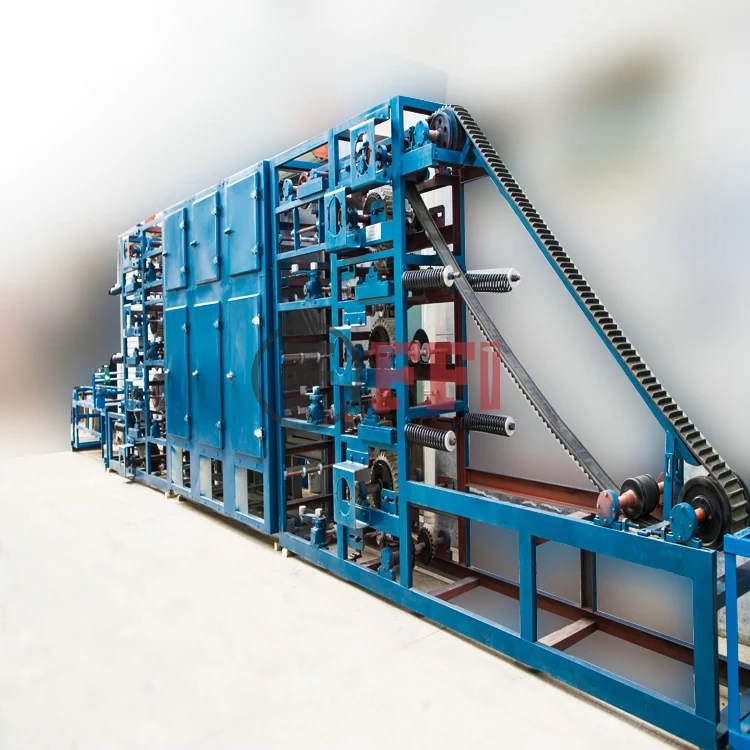

Helix powder coating machine |

Coat the mixed powder onto the wire. |

10 |

Head-Tail Grinder machine |

To grind the head and tail into standard shape. |

11 |

Electrode eccentric measuring Instrument |

Eccentric checking. |

12 |

Control panel for spiral line |

Main control of electricity. |

13 |

Auxiliary line machine |

Internal conveying. |

14 |

Box type hot air circulation drying furnace(electricity) |

Drying the coating on the core. |

15 |

Words printer |

Printing dates or brand name. |

16 |

Shrink packaging machine |

Plastic packing. |

17 |

Strapping machine |

Wrapping. |

18 |

Reclaiming machine |

Peel the coating off. |

19 |

Straightening machine |

Straighten the wire. |

20 |

Vibrating screen |

To filter the recycled coating. |

EN

EN