Product Description

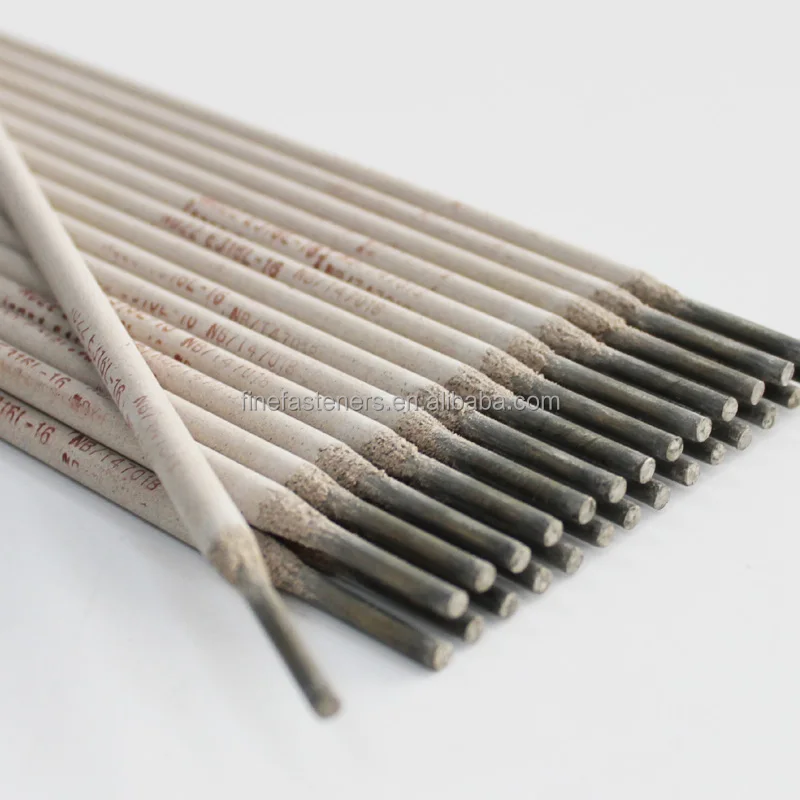

are you Searching for a welding that is high-grade which will certainly help you establish you develop up with simpleness? Browse just forget about contrasted to your FFI Tailor Welding Electrode. This procedure that's incredible produced specially that may help you Aswell as your welding requirements, whether you're a welder that is expert maybe beginning.

The FFI Tailor Welding Electrode is made of premium-grade services and products, making sure its resilience also stability in lot of your welding jobs. It is created to offer you by having a welding, which is amazing, therefore of these develop that is unique that work with you to will get the work completed with very initiative that is little.

Along with the FFI Tailor Welding Electrode, a product will be acquired by you that is advanced can assist you to achieve the leads which are expected you develop set up. It is crafted with accuracy, production definite you should swiftly jobs that will also be complete easily. The product is wonderful for folks attempting to get to optimize their welding gaming in their grow setup because it is easy to use and setup.

Just what collections the FFI Tailor Welding Electrode besides a number of other item and services whenever you appear during the marketplace is its customizability. This welding electrode is individualized to fit your task needs in your business, production it unbelievably versatile along with flexible. Regardless of what quantity of welding you need to do this is the suitable one, the FFI Tailor Welding Electrode can be adjusted to check on with specific needs regarding the work.

The FFI Tailor Welding Electrode is easy, also for people which have actually do not ever actually bonded previously. The electrodes are really a task that is straightforward use like you don't need to setup this product for a lot of time instead you can use it whenever you need it, which means that criteria included with the item are obvious also succinct. It really is feasible to welding that is beginning almost no time that's true use of this product, also should you not have actually welding experience this is positively previous.

Being an easy task to make use of, the FFI Tailor Welding Electrode can in addition be risk-free to utilize. It's created to shield you against dangerous fumes and also triggers, ensuring at danger you can also work securely and effectively without placing on your own very own.

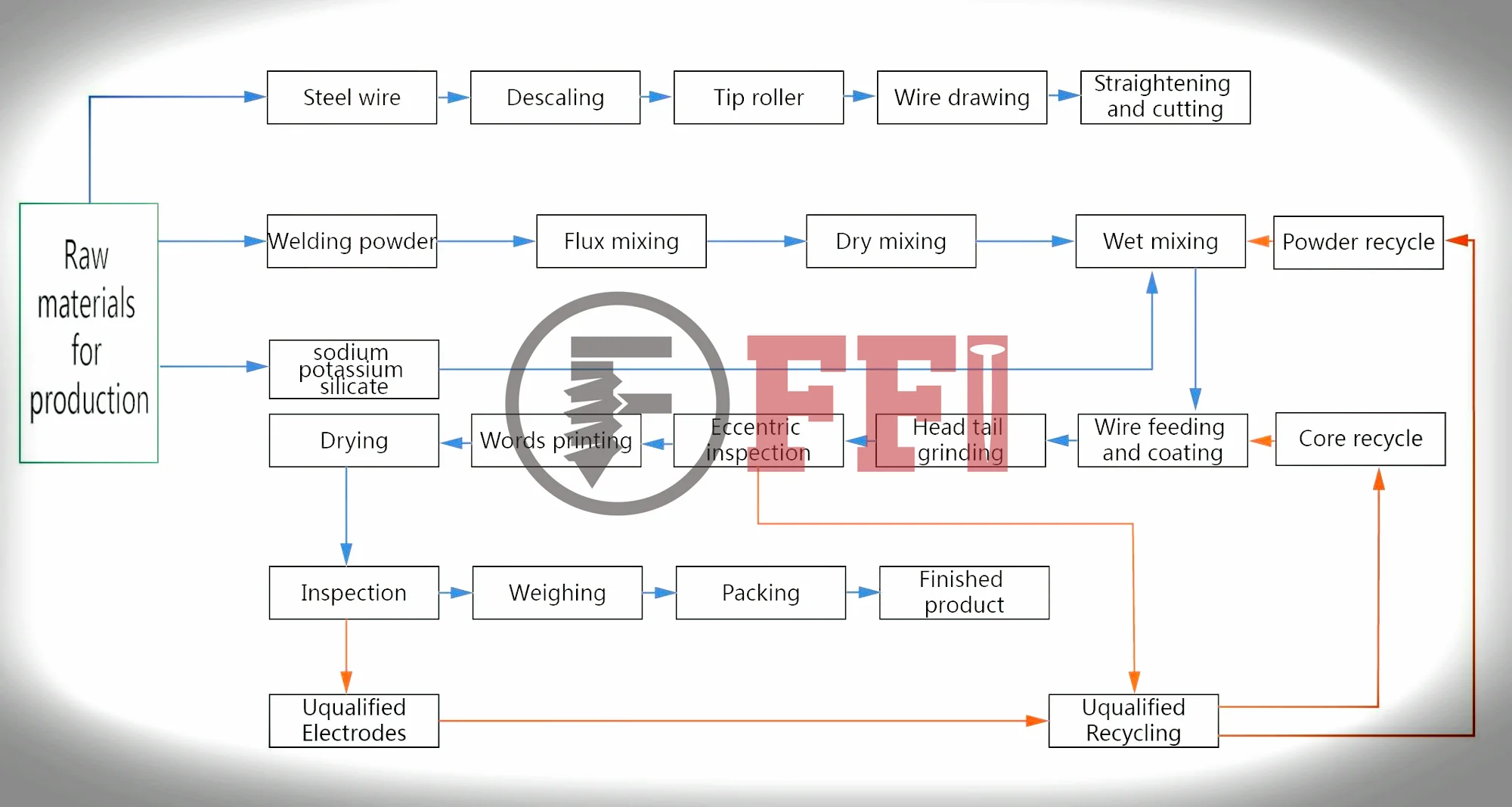

No. |

Equipment |

Function |

1 |

Descaling machine |

Remove the dust from the wire. |

2 |

Tip roller |

Sharpen the tip of wire. |

3 |

Butt-welding machine |

To weld the wire tips when 1 roll is finished. |

4 |

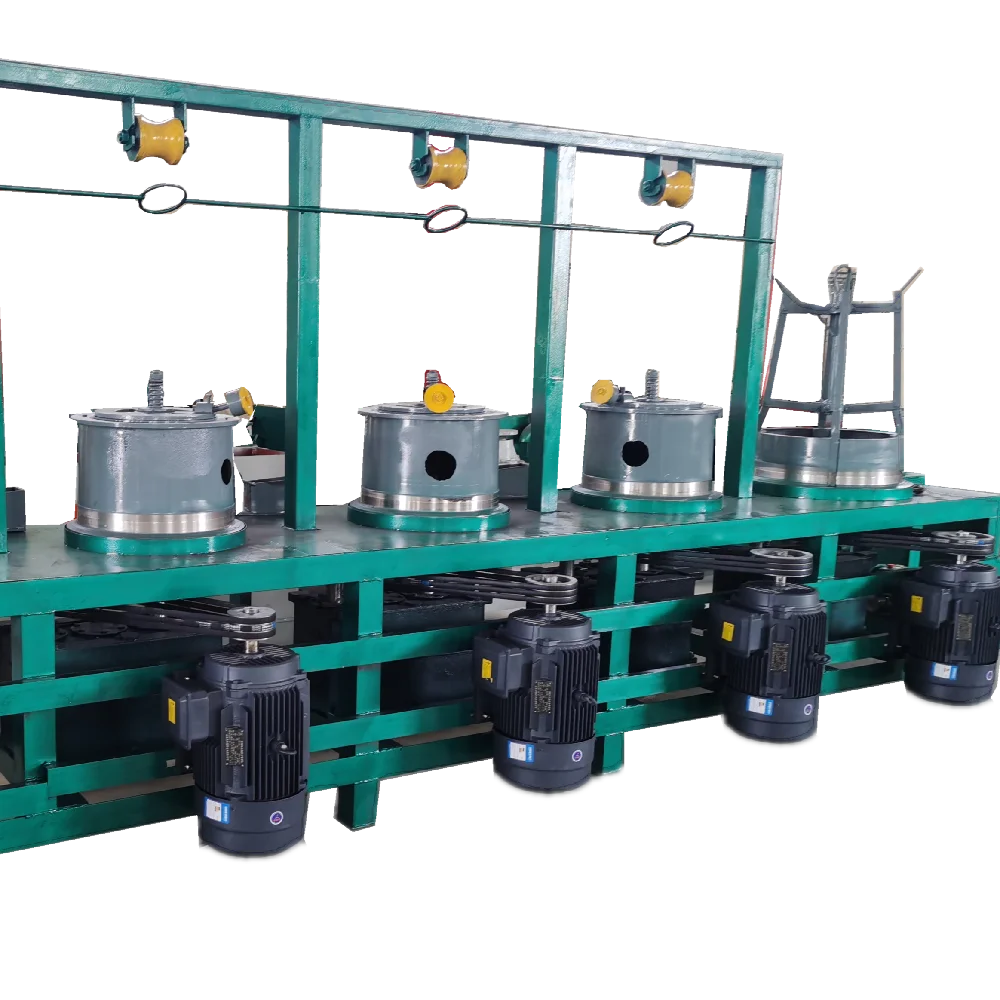

Wire drawing machine |

To draw the wire into diameter needed. |

5 |

Single arm crane |

To lift the wires. |

6 |

Wire cutting machine |

To cut wire into size. |

7 |

Mixing Machines Double "S" Type |

Mix the powder for coating. |

8 |

Silicate Mixer |

Silicate stirring barrel is special for stirring liquid silicate. |

8 |

Wire-feed machine |

Wire supply. |

9 |

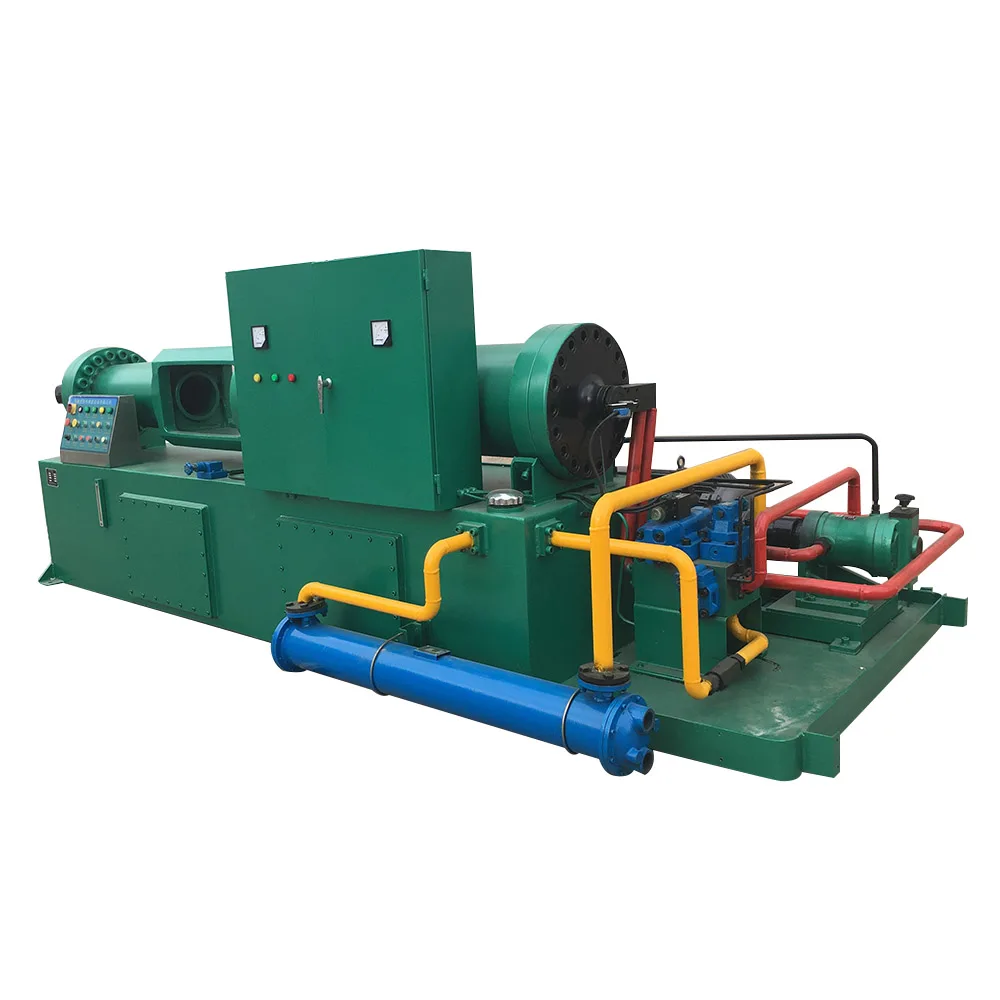

Hydraulic powder coating machine |

Coat the mixed powder onto the wire. |

10 |

Head-Tail Grinder machine |

To grind the head and tail into standard shape. |

11 |

Electrode eccentric measuring Instrument |

Eccentric checking. |

12 |

Control panel for spiral line |

Main control of electricity. |

13 |

Auxiliary line machine |

Internal conveying. |

14 |

Box type hot air circulation drying furnace(electricity) |

Drying the coating on the core. |

15 |

Words printer |

Printing dates or brand name. |

16 |

Shrink packaging machine |

Plastic packing. |

17 |

Strapping machine |

Wrapping. |

18 |

Reclaiming machine |

Peel the coating off. |

19 |

Straightening machine |

Straighten the wire. |

20 |

Vibrating screen |

To filter the recycled coating. |

EN

EN