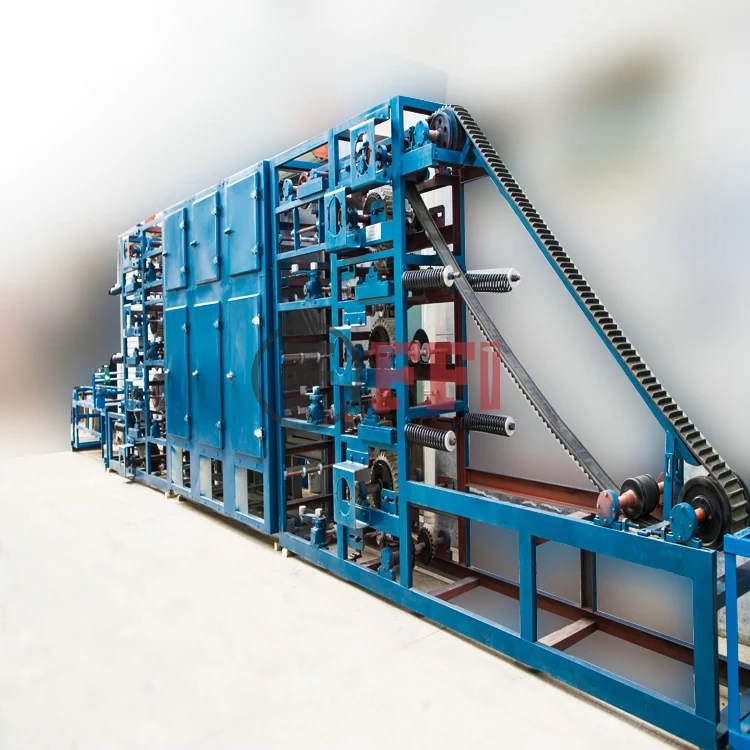

Product Description

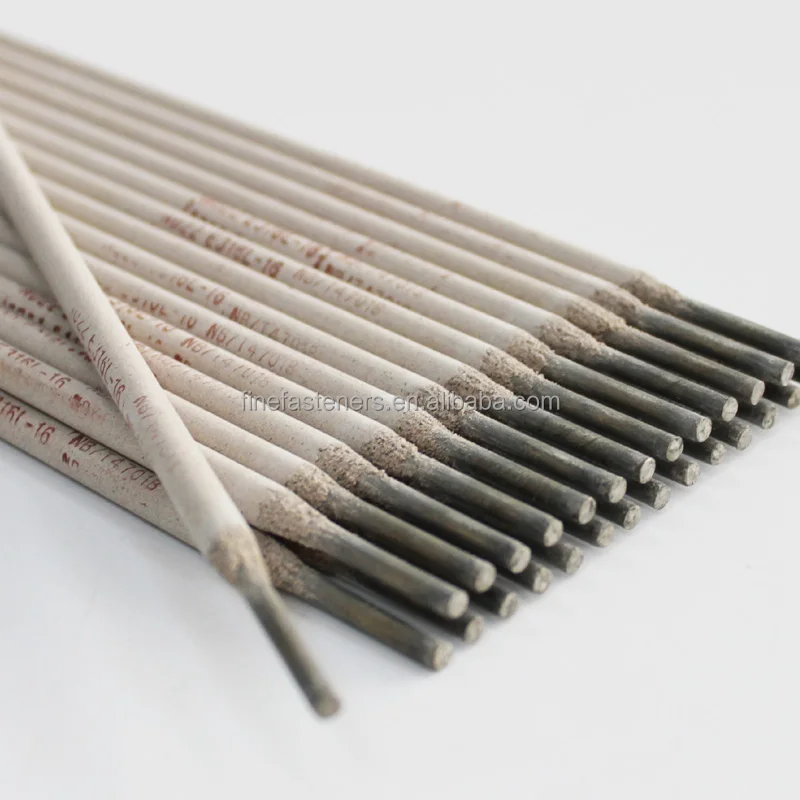

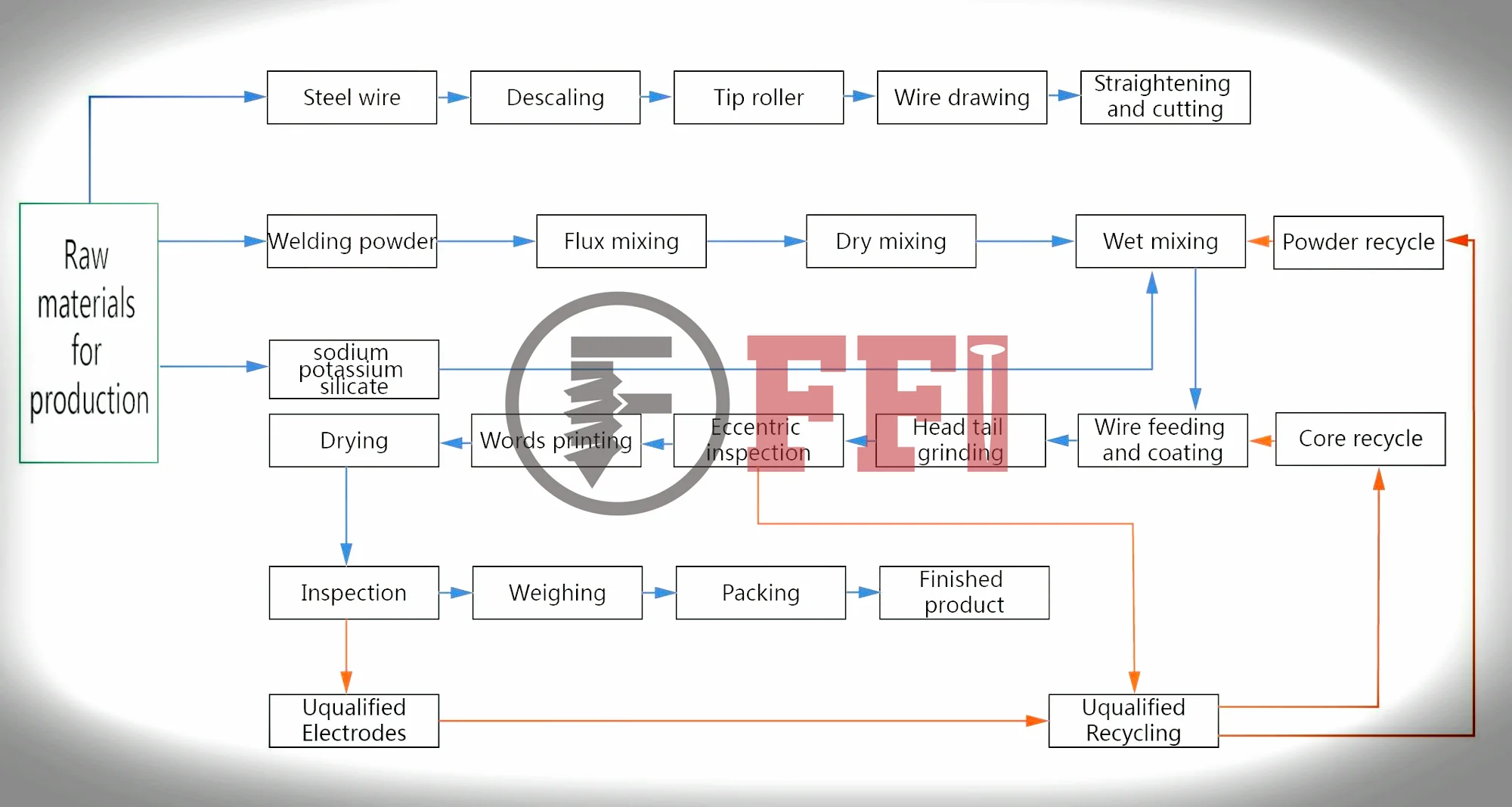

Have you been sick and tired with purchasing welding electrodes that don't suit your unique welding requirements? Look no further than FFI's Customize Welding Electrode machine that is making. You are enabled by this machine to generate welding electrodes personalized to your specs which can be precise.

The FFI Customize Welding Electrode device this is certainly making simple to use and very efficient. It features advanced level technology that enables for precise control related to welding electrode's structure, ensuring that it meets your preferences which can be exact.

This welding electrode machine that is making an easy task to run, making it perfect for those people who are a new comer to the welding industry. It features an screen this is certainly intuitive permits procedure that is smooth irrespective of experience level.

The FFI Customize Welding Electrode device that is making very built and durable to final. The machine is made of top-notch materials and comes with a robust design that will withstand even the running conditions which may be toughest.

This welding electrode machine that is making extremely versatile and will be used to produce a array that is wide of electrodes. This device can accommodate your requirements whether you need electrodes for MIG welding, TIG welding, or other welding kinds.

The FFI Customize Welding Electrode machine that is making a investment that is fantastic virtually any welding business wanting to create individualized welding electrodes. You might be helped as a result of it reduce costs, increase efficiency, while increasing the grade of an individual's welding work.

No. |

Equipment |

Function |

1 |

Descaling machine |

Remove the dust from the wire. |

2 |

Tip roller |

Sharpen the tip of wire. |

3 |

Butt-welding machine |

To weld the wire tips when 1 roll is finished. |

4 |

Wire drawing machine |

To draw the wire into diameter needed. |

5 |

Single arm crane |

To lift the wires. |

6 |

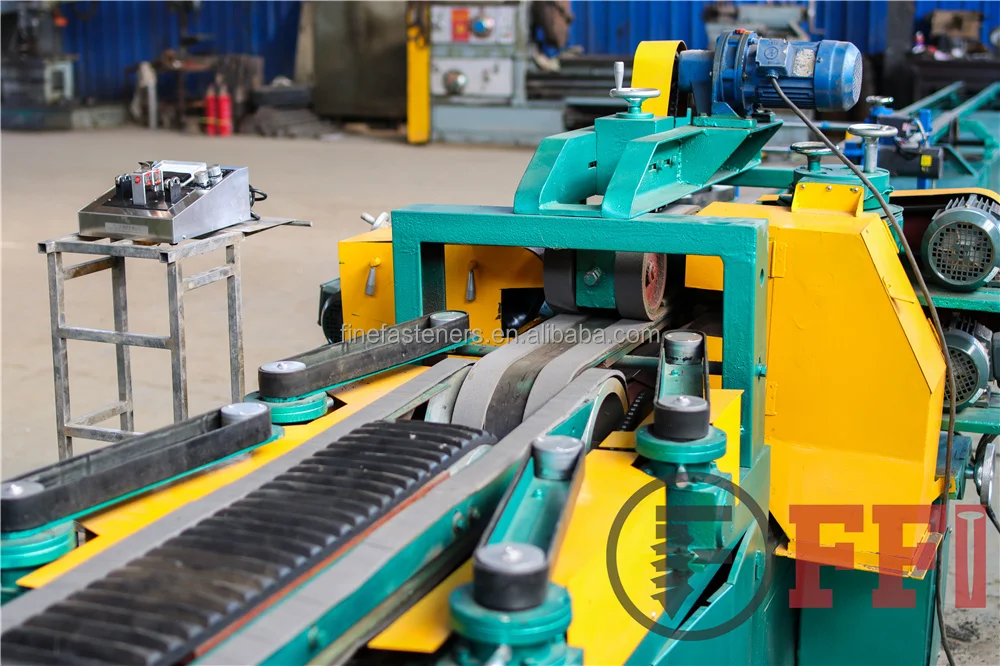

Wire cutting machine |

To cut wire into size. |

7 |

Mixing Machines Double "S" Type |

Mix the powder for coating. |

8 |

Silicate Mixer |

Silicate stirring barrel is special for stirring liquid silicate. |

8 |

Wire-feed machine |

Wire supply. |

9 |

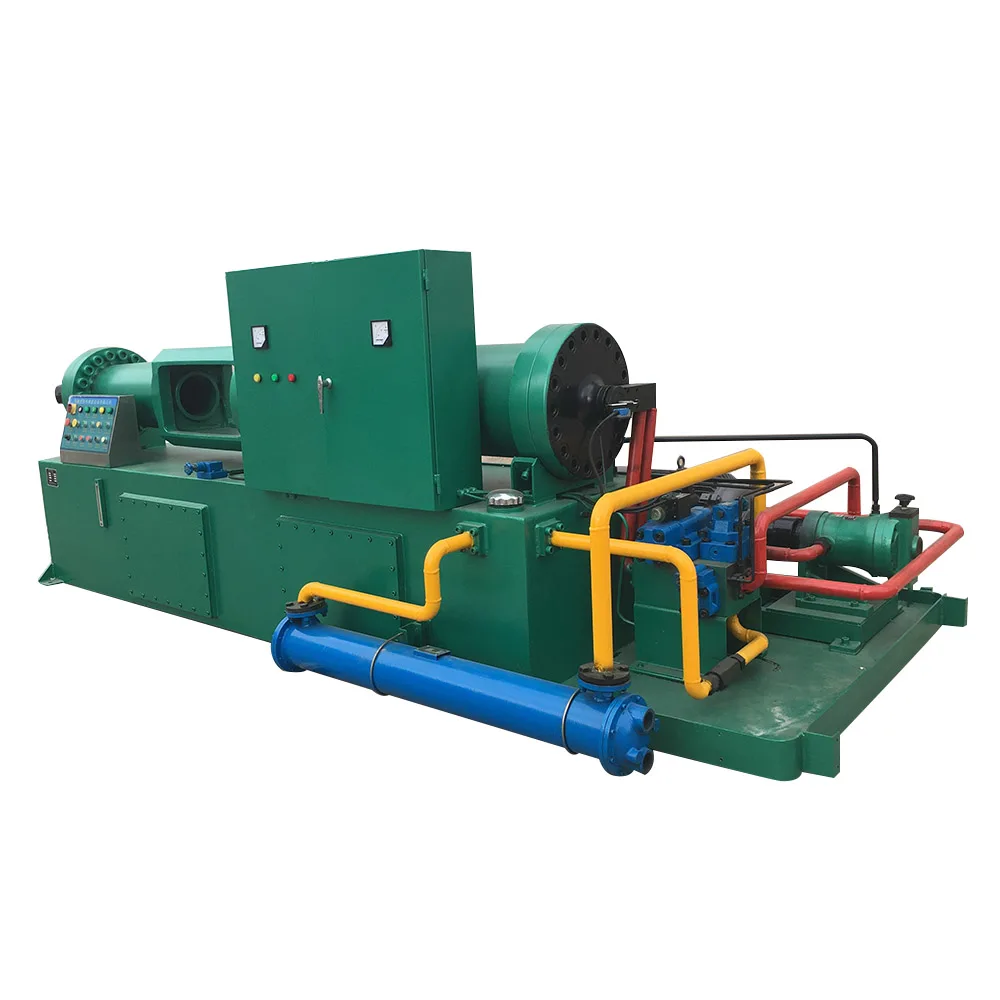

Hydraulic powder coating machine |

Coat the mixed powder onto the wire. |

10 |

Head-Tail Grinder machine |

To grind the head and tail into standard shape. |

11 |

Electrode eccentric measuring Instrument |

Eccentric checking. |

12 |

Control panel for spiral line |

Main control of electricity. |

13 |

Auxiliary line machine |

Internal conveying. |

14 |

Box type hot air circulation drying furnace(electricity) |

Drying the coating on the core. |

15 |

Words printer |

Printing dates or brand name. |

16 |

Shrink packaging machine |

Plastic packing. |

17 |

Strapping machine |

Wrapping. |

18 |

Reclaiming machine |

Peel the coating off. |

19 |

Straightening machine |

Straighten the wire. |

20 |

Vibrating screen |

To filter the recycled coating. |

EN

EN