Product Description

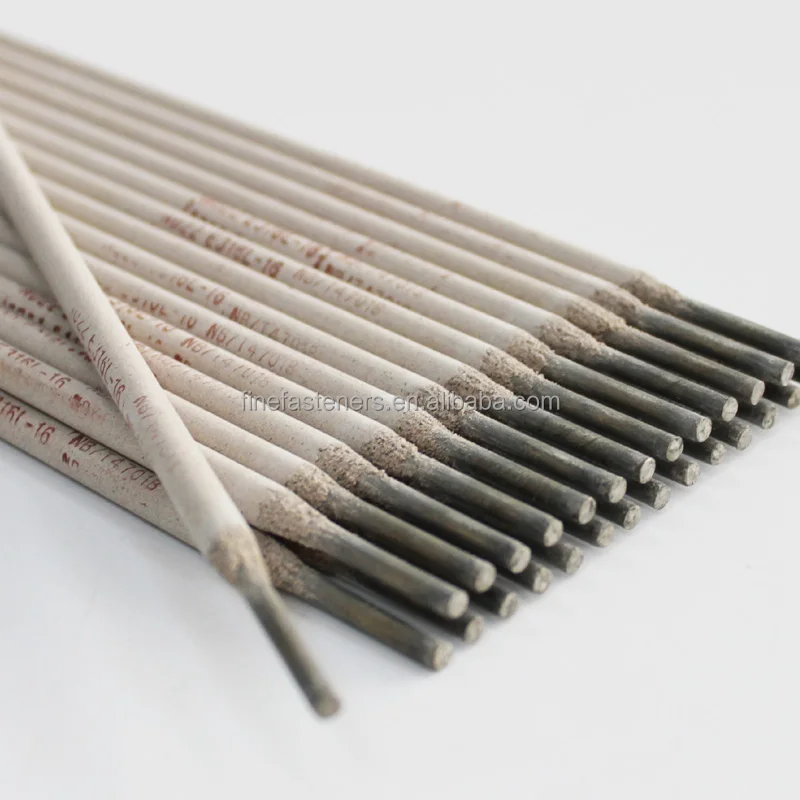

The FFI Welding Rod Making Machine is just a machine that is high-tech is created for professional welders trying to find a simple yet effective, dependable and way that is cost-effective produce welding rods. You raise up your productivity and increase the quality of your work whether you are manufacturing rods for individual use or purposes that are commercial this machine will help.

The FFI Welding Rod machine this is certainly making built using materials that are high-quality guarantee durability, longevity and precision. It truly is built with state-of-the-art technology and features that enable smooth and procedure that is rendering that is trouble-free the best choice for newbies and seasoned welders alike.

The device is highly customizable and certainly will be adjusted to fulfill welding this is certainly specifications that are different compromising on effectiveness or accuracy. It can be used to build an assortment that is wide of sizes and shapes, including cylindrical and rectangular rods, relating to your specific welding requirements.

The FFI Welding Rod machine this is certainly making with a user-friendly screen that is an easy task to navigate and operate. It comes with a control that is digital that allows one to monitor and regulate the manufacturing process accurately, ensuring that you have consistent and high-quality welding rods each and every time.

One of several better grounds for the FFI Welding Rod Making Machine is its power effectiveness. It uses technology that is innovative reduces power consumption, making it an selection that is eco-friendly welders who are aware of their carbon impact.

The FFI Welding Rod Making Machine is made to be low-maintenance, which means that with servicing the equipment regularly that it is possible to concentrate on your welding work and never having to concern yourself. Additionally it is super easy to clean and sanitize, that will help you to definitely reduce steadily the risk of contamination and cross-contamination during manufacturing.

No. |

Equipment |

Function |

1 |

Descaling machine |

Remove the dust from the wire. |

2 |

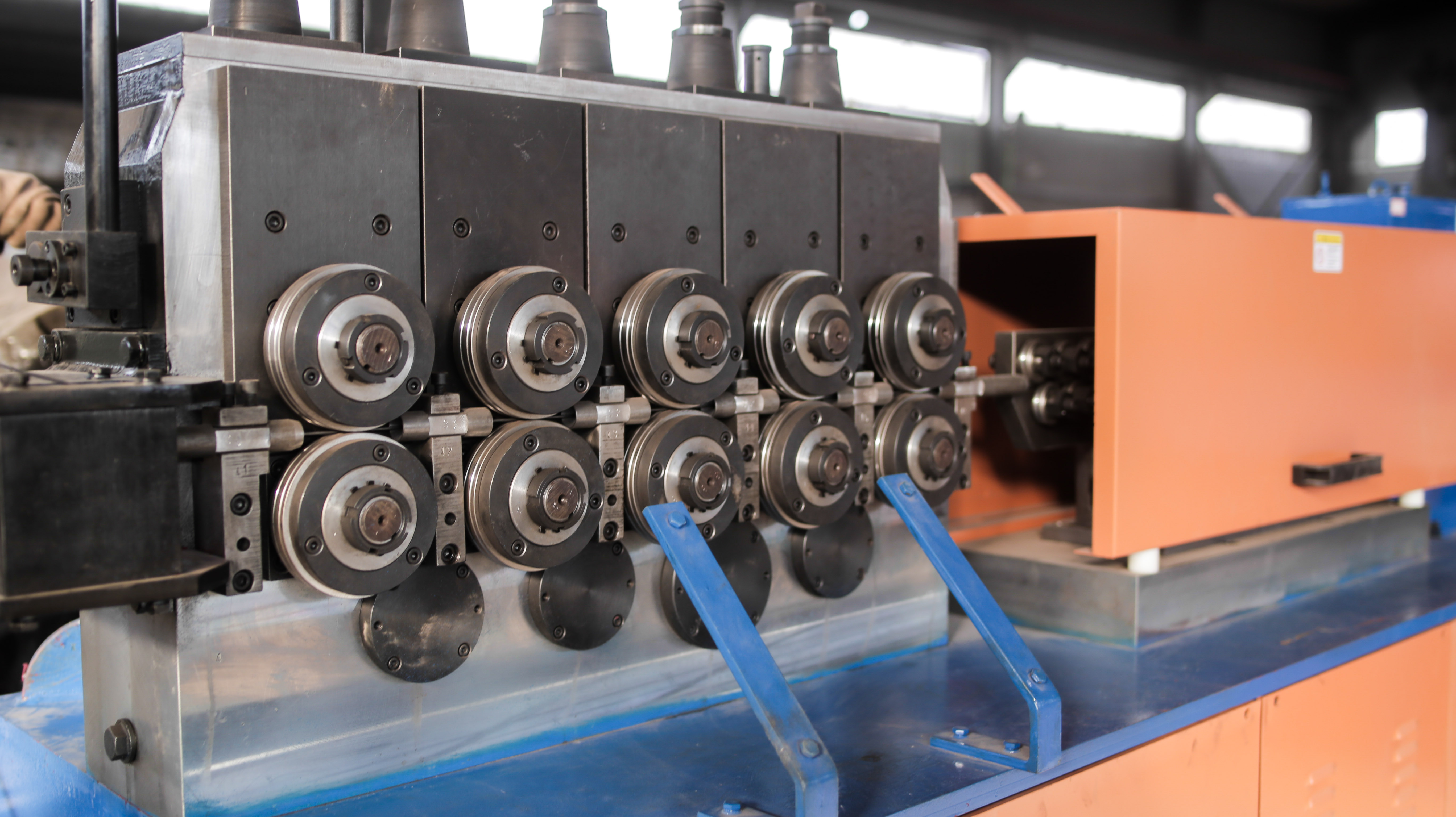

Tip roller |

Sharpen the tip of wire. |

3 |

Butt-welding machine |

To weld the wire tips when 1 roll is finished. |

4 |

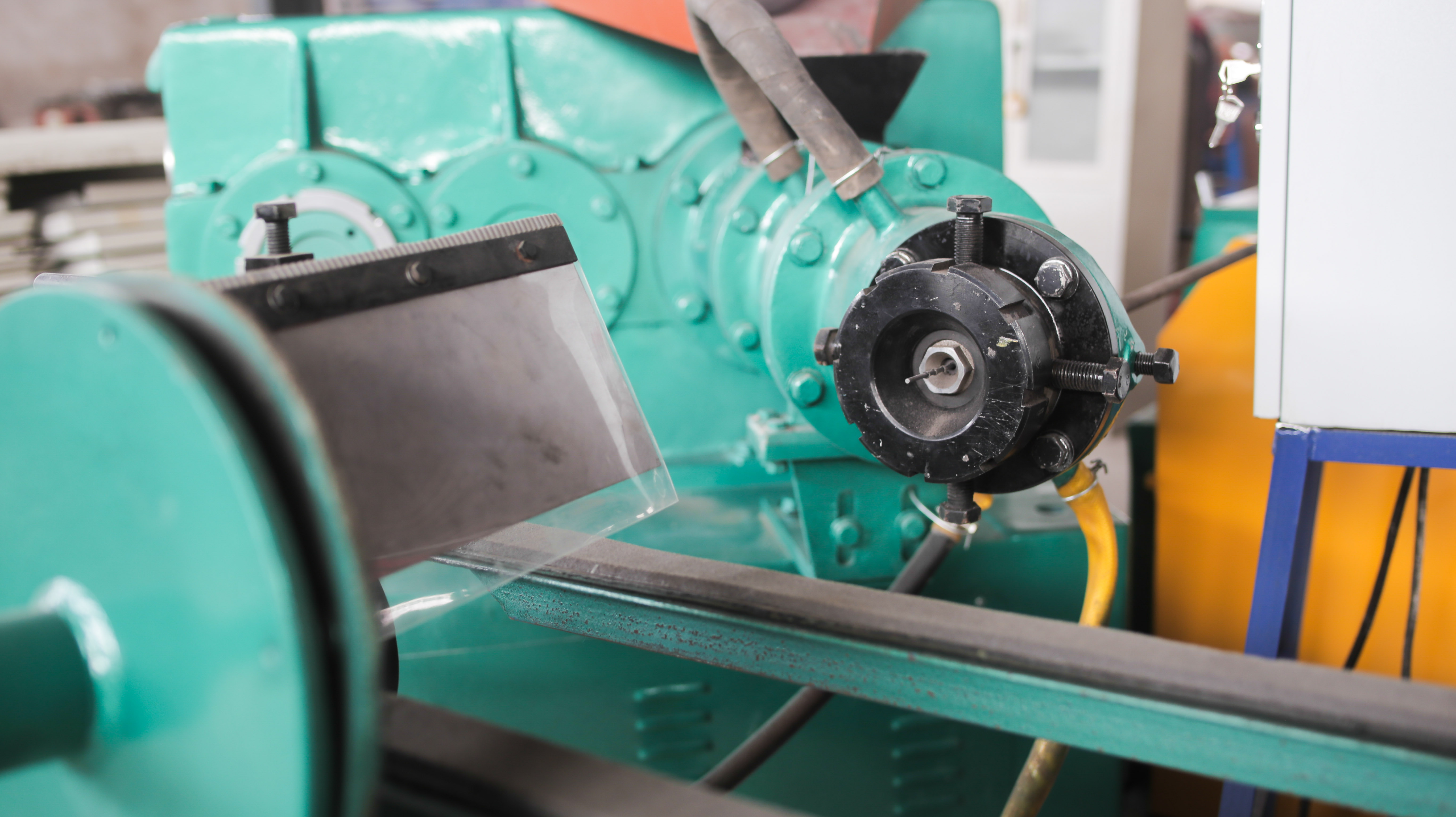

Wire drawing machine |

To draw the wire into diameter needed. |

5 |

Single arm crane |

To lift the wires. |

6 |

Wire cutting machine |

To cut wire into size. |

7 |

Mixing Machines Double "S" Type |

Mix the powder for coating. |

8 |

Silicate Mixer |

Silicate stirring barrel is special for stirring liquid silicate. |

8 |

Wire-feed machine |

Wire supply. |

9 |

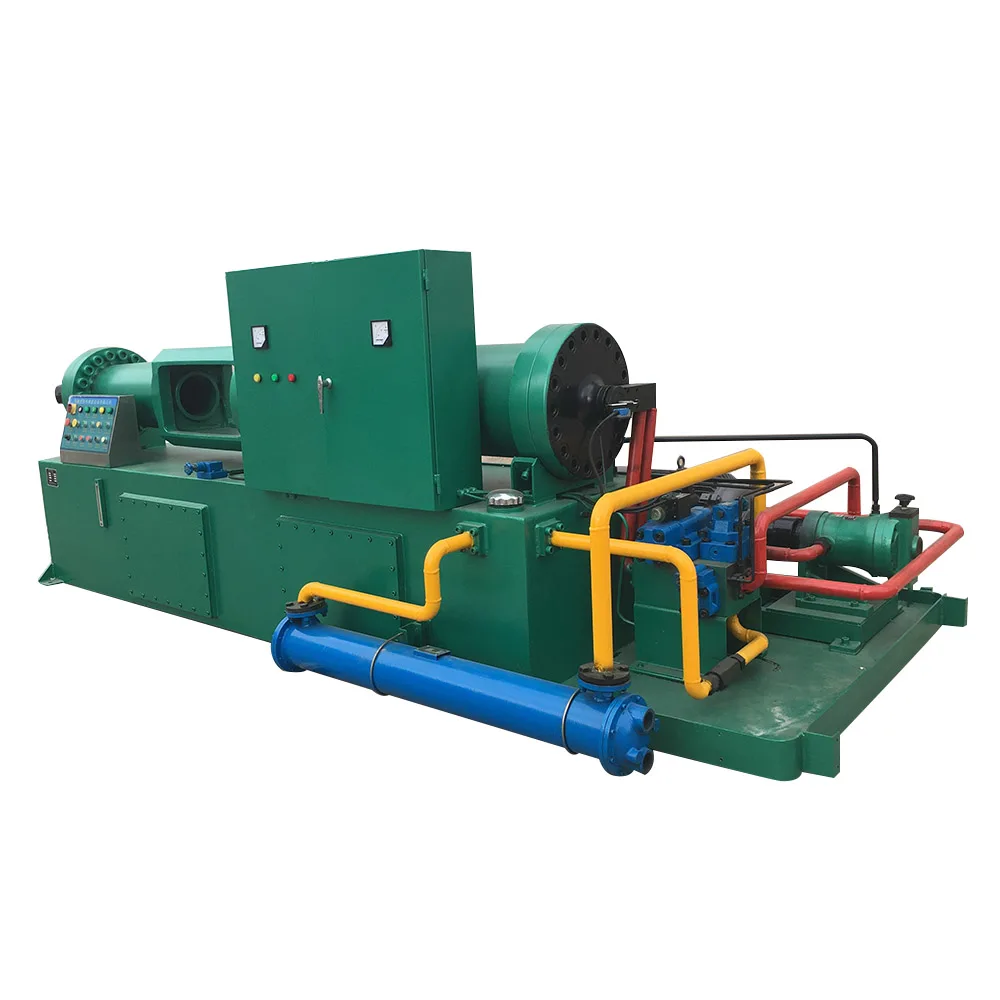

Hydraulic powder coating machine |

Coat the mixed powder onto the wire. |

10 |

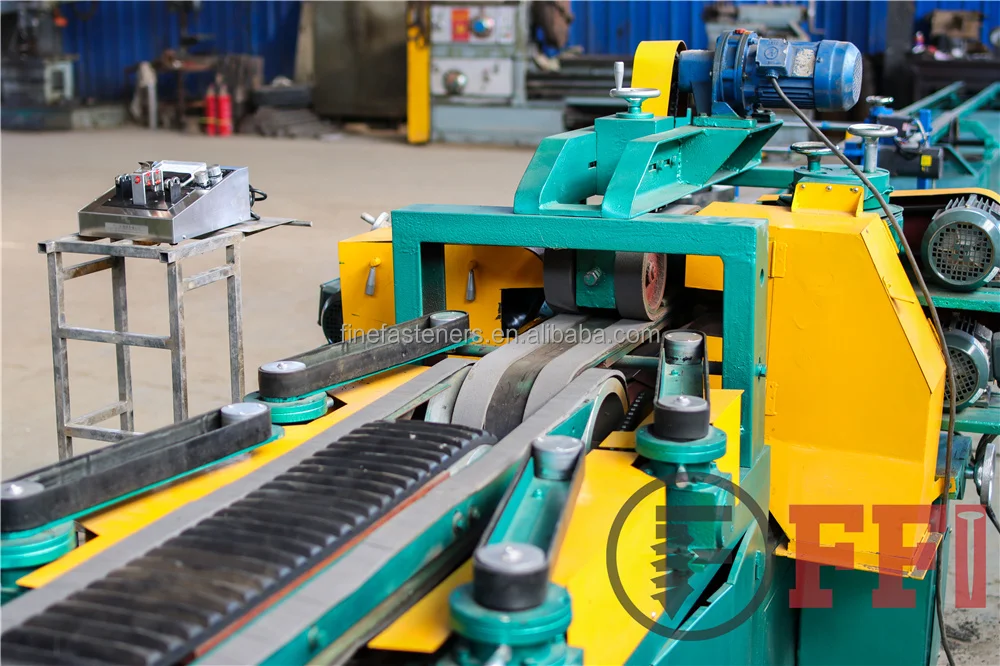

Head-Tail Grinder machine |

To grind the head and tail into standard shape. |

11 |

Electrode eccentric measuring Instrument |

Eccentric checking. |

12 |

Control panel for spiral line |

Main control of electricity. |

13 |

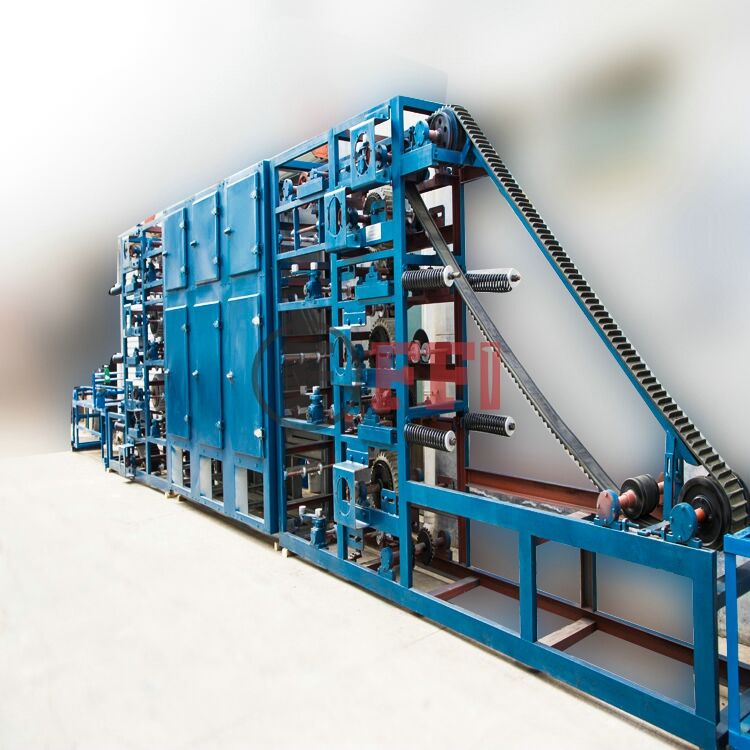

Auxiliary line machine |

Internal conveying. |

14 |

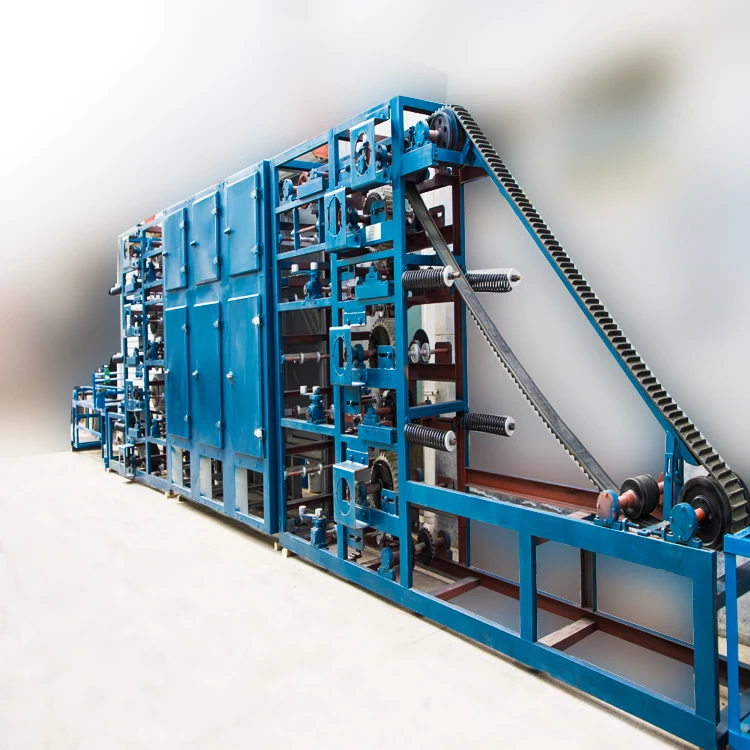

Box type hot air circulation drying furnace(electricity) |

Drying the coating on the core. |

15 |

Words printer |

Printing dates or brand name. |

16 |

Shrink packaging machine |

Plastic packing. |

17 |

Strapping machine |

Wrapping. |

18 |

Reclaiming machine |

Peel the coating off. |

19 |

Straightening machine |

Straighten the wire. |

20 |

Vibrating screen |

To filter the recycled coating. |

EN

EN