Product Description

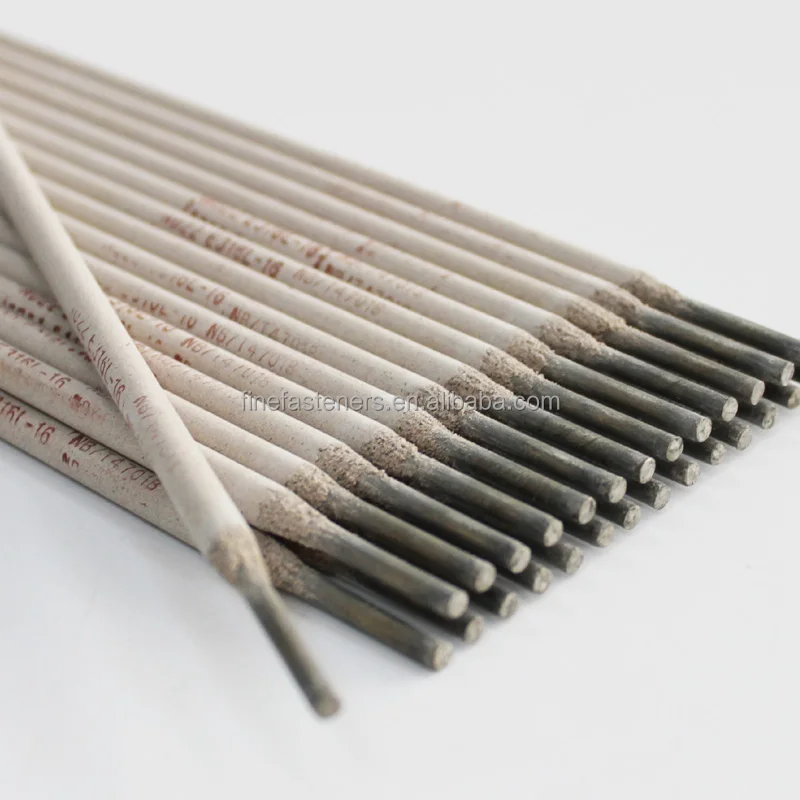

If you're a welder, you understand that having the right tools is paramount to attaining the quality welds that are greatest. One device in specific that you ought to don't ever skimp on is the welding electrode steel welding and wire flux. Then when it comes down seriously to choosing the brand this is certainly better of welding electrode steel wire and welding flux, FFI is simply a top choice for most welders.

FFI welding electrode steel wire and welding flux are recognized for their quality this is certainly excellent, and reliability. That is as a result of their utilization of premium materials and cutting-edge techniques that are manufacturing produce a product you are going to rely on for perhaps the most welding that is demanding.

Among the standout options that come with FFI welding electrode steel cable is its tensile that is strength that is high. This means it could withstand loads which are hefty vibrations that are strong breaking or becoming damaged. Additionally, its metal that is top-quality structure that it produces strong, accurate welds with exceptional penetration and fusion.

As well as its superior welding abilities, FFI welding electrode metal wire also offers a level this is certainly a lot of. It's suitable for an assortment this is certainly wide of methods, including MIG, TIG, and stick welding. What this means is for many welding jobs, from automotive repairs and steel fabrication to construction and commercial applications which you can use it.

When it comes to flux this is certainly FFI that is welding offers variety of choices to fit your unique welding needs. Their flux is specially formulated to provide security this is certainly great oxidation and other atmospheric contaminants which will compromise your welds. Also, it makes a smooth, high-quality finish with minimal spatter and slag.

Another standout feature of FFI welding flux is its ease of use. It comes in a variety of types, including powders, pastes, and fluids, that makes it an task that is easy use and acquire a grip on. And will also be certain that you're using a item that could create the best possible outcomes everytime since it is designed to work seamlessly with FFI welding electrode metal cable.

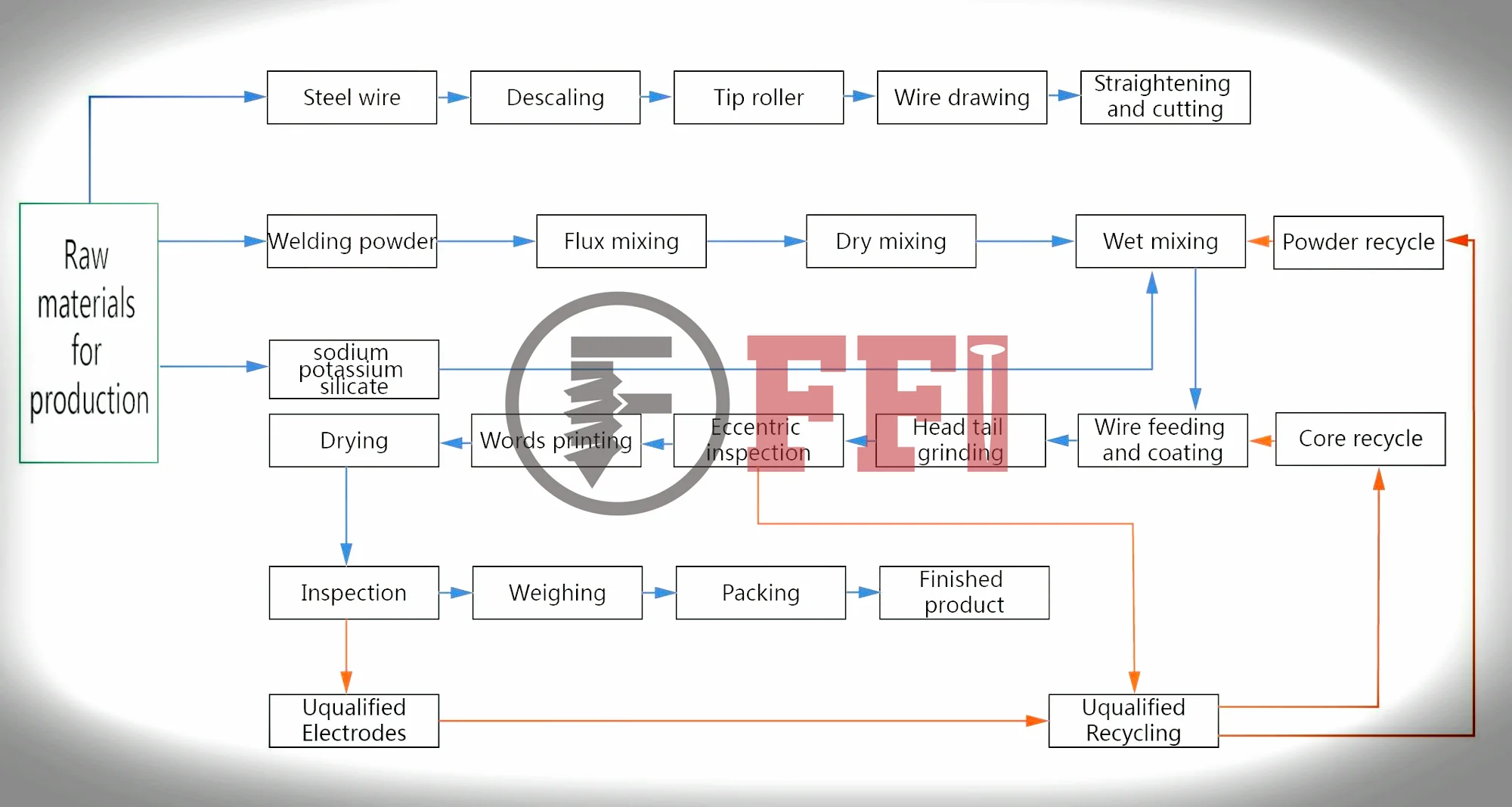

No. |

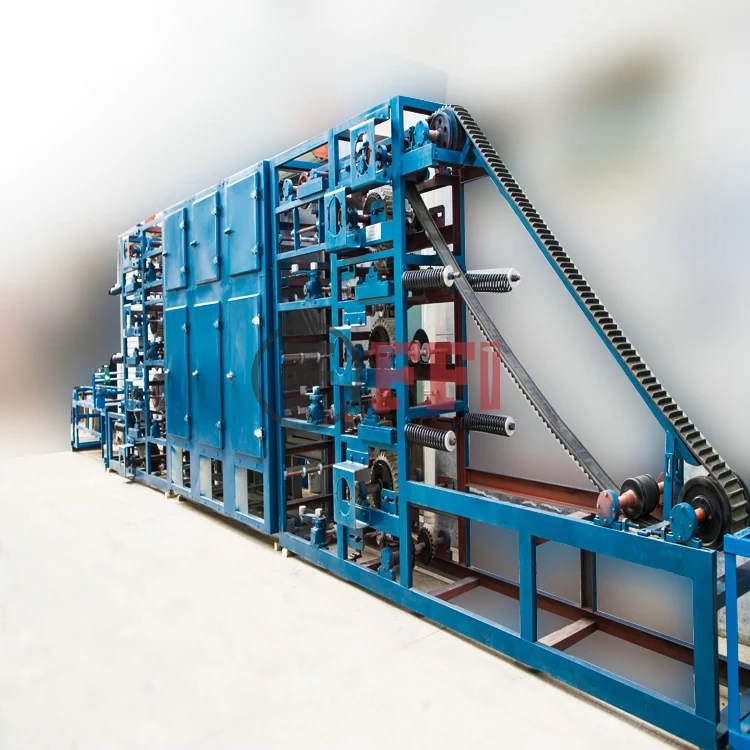

Equipment |

Function |

1 |

Descaling machine |

Remove the dust from the wire. |

2 |

Tip roller |

Sharpen the tip of wire. |

3 |

Butt-welding machine |

To weld the wire tips when 1 roll is finished. |

4 |

Wire drawing machine |

To draw the wire into diameter needed. |

5 |

Single arm crane |

To lift the wires. |

6 |

Wire cutting machine |

To cut wire into size. |

7 |

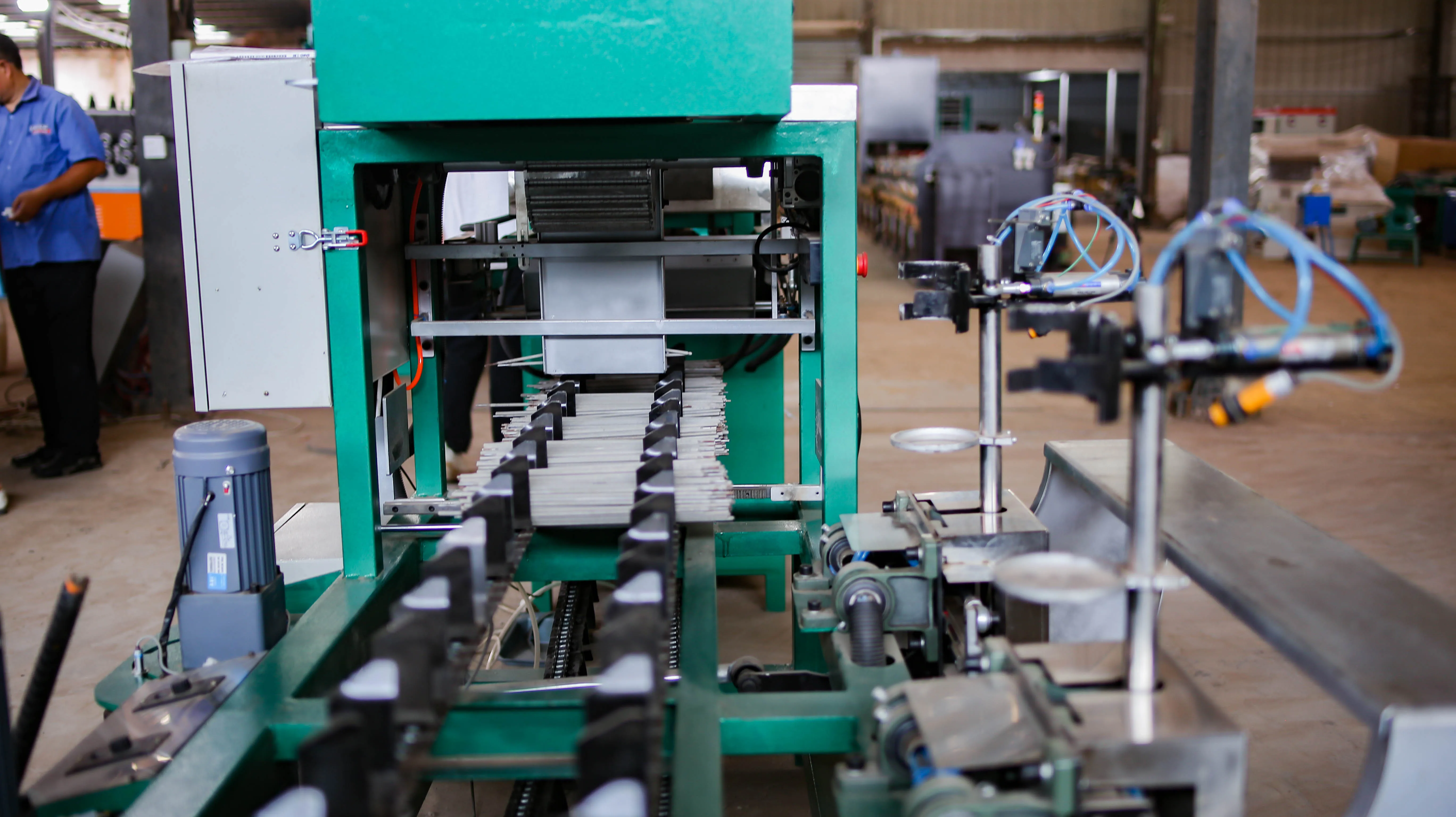

Mixing Machines Double "S" Type |

Mix the powder for coating. |

8 |

Silicate Mixer |

Silicate stirring barrel is special for stirring liquid silicate. |

8 |

Wire-feed machine |

Wire supply. |

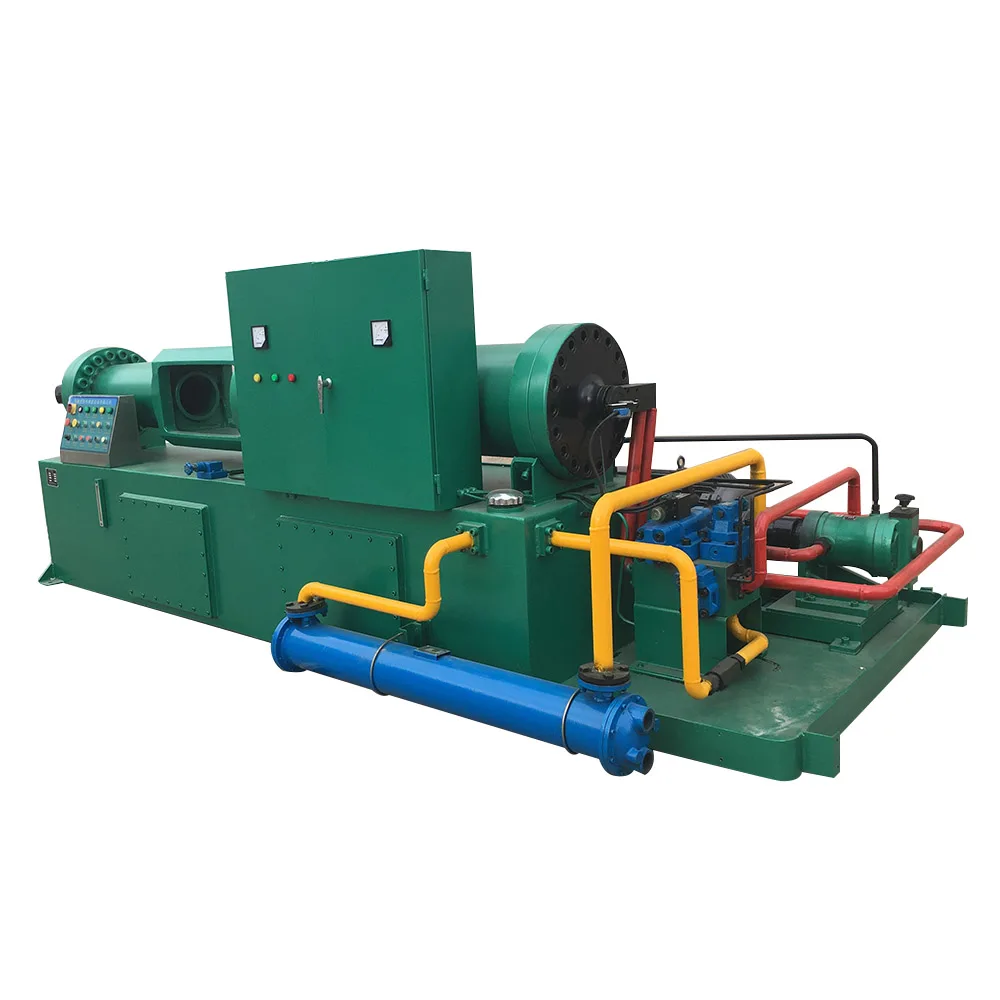

9 |

Hydraulic powder coating machine |

Coat the mixed powder onto the wire. |

10 |

Head-Tail Grinder machine |

To grind the head and tail into standard shape. |

11 |

Electrode eccentric measuring Instrument |

Eccentric checking. |

12 |

Control panel for spiral line |

Main control of electricity. |

13 |

Auxiliary line machine |

Internal conveying. |

14 |

Box type hot air circulation drying furnace(electricity) |

Drying the coating on the core. |

15 |

Words printer |

Printing dates or brand name. |

16 |

Shrink packaging machine |

Plastic packing. |

17 |

Strapping machine |

Wrapping. |

18 |

Reclaiming machine |

Peel the coating off. |

19 |

Straightening machine |

Straighten the wire. |

20 |

Vibrating screen |

To filter the recycled coating. |

EN

EN