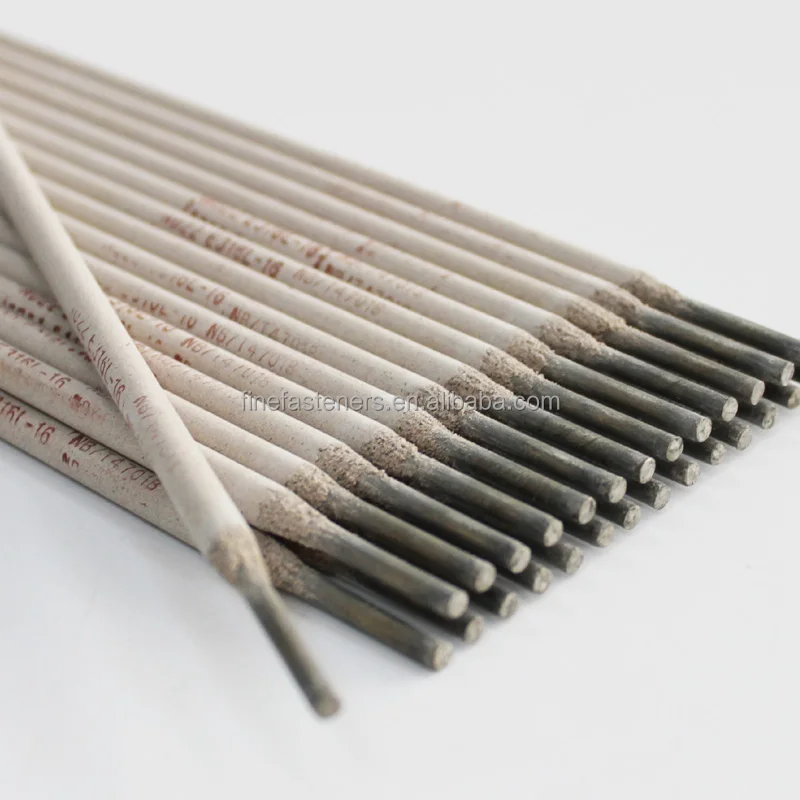

Product Description

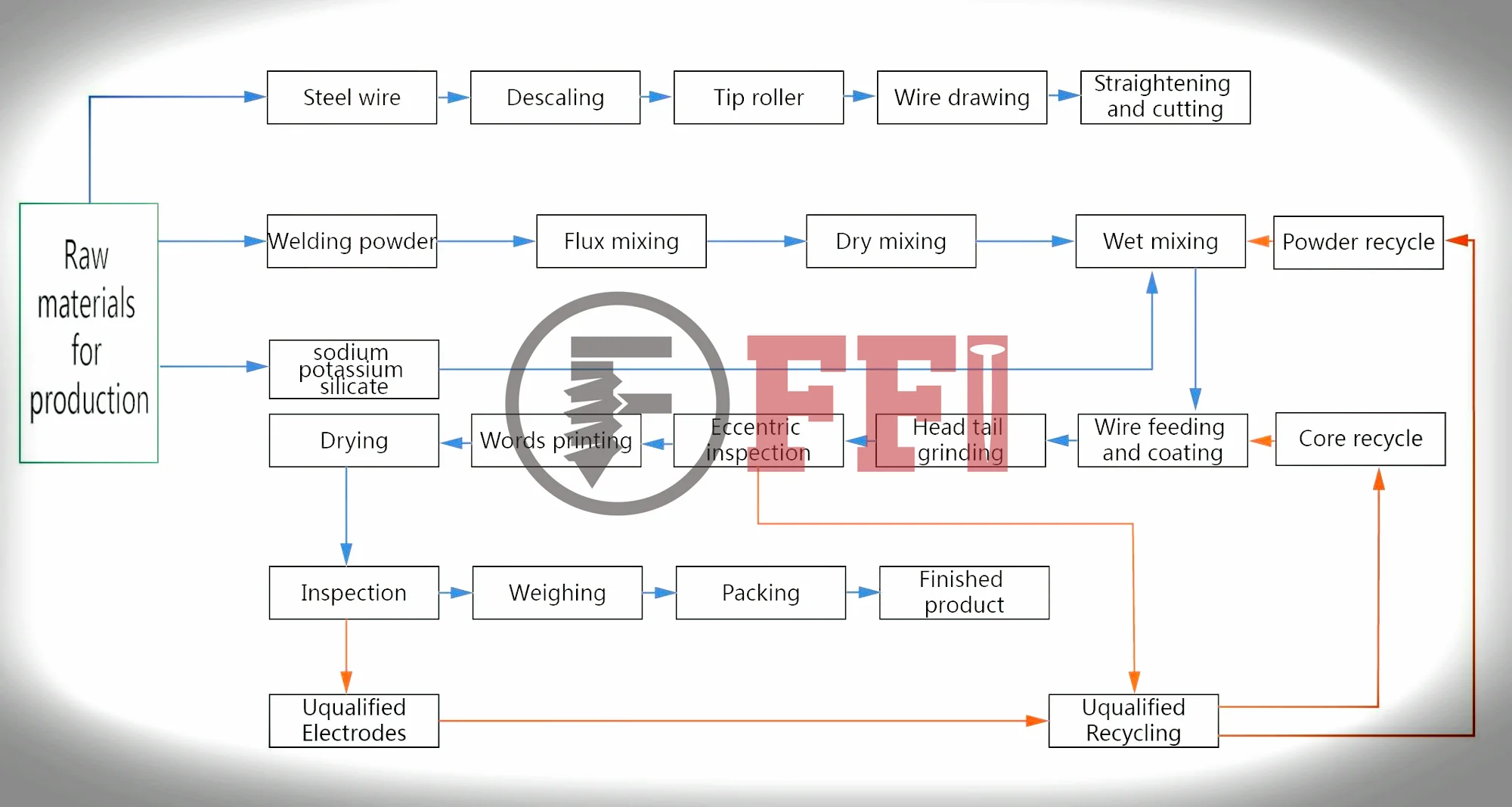

You understand how important it is to manufacture welding that is high-quality if you're into the welding industry. That’s why you need to spend money on the Welding Rod manufacturing Line devices being making FFI. The unit are made to allow you to automate the process of producing welding rods of excellent quality and consistency, helping you save both right time and money.

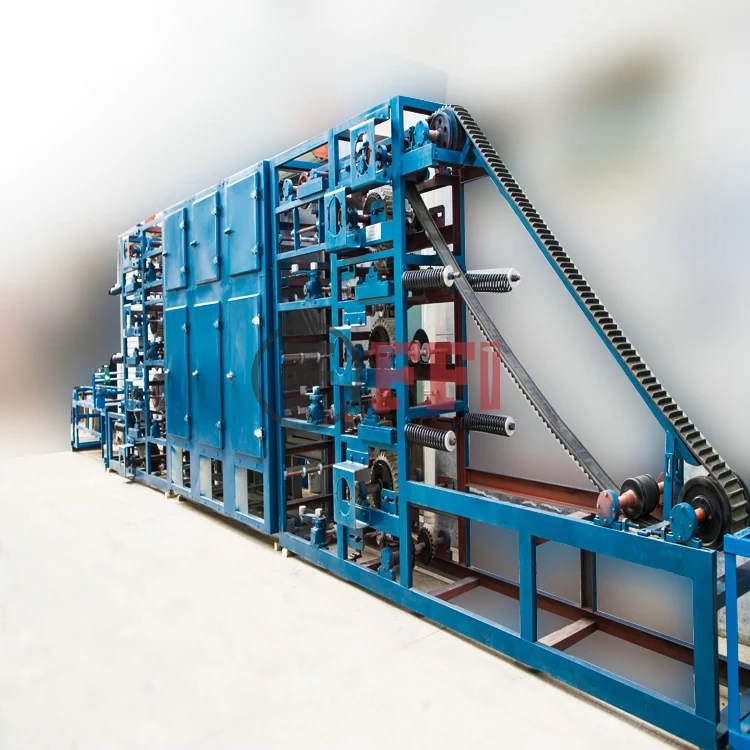

The needs of our consumers at FFI, we pride ourselves in providing very efficient and equipment that is dependable satisfies. Our Welding Rod Production Line devices that are making no exception. They are manufactured utilising the technology this is certainly latest and also the most materials that are readily useful ensure they function optimally and withstand the test of that time.

With your Welding Rod line that is manufacturing that can be causing you to can create welding rods of varied kinds, sizes, and forms. They are designed to accommodate various kinds welding materials, such as for example carbon steel, aluminum, stainless, and more. The devices are also easy to run, due to their graphical user interface that is user-friendly that you take notice of the production procedure making necessary changes in order to make sure quality control.

Our Welding Rod line that is manufacturing which are often making additionally able to creating high volumes of welding rods quickly. What this means is the demands is met by you of your respective customers while boosting your revenue. The machines are manufactured to run continuously without slowing or overheating down, ensuring that you optimize your manufacturing capacity.

An additional benefit of your Welding Rod Production Line making machines is the upkeep this is certainly low cost. They've been built to last, and that means you can save cash on repairs and replacements. Also, our machines are eco-friendly, them perfect for sustainable manufacturing while they consume less energy and emit exhaust that is minimal, making.

No. |

Equipment |

Function |

1 |

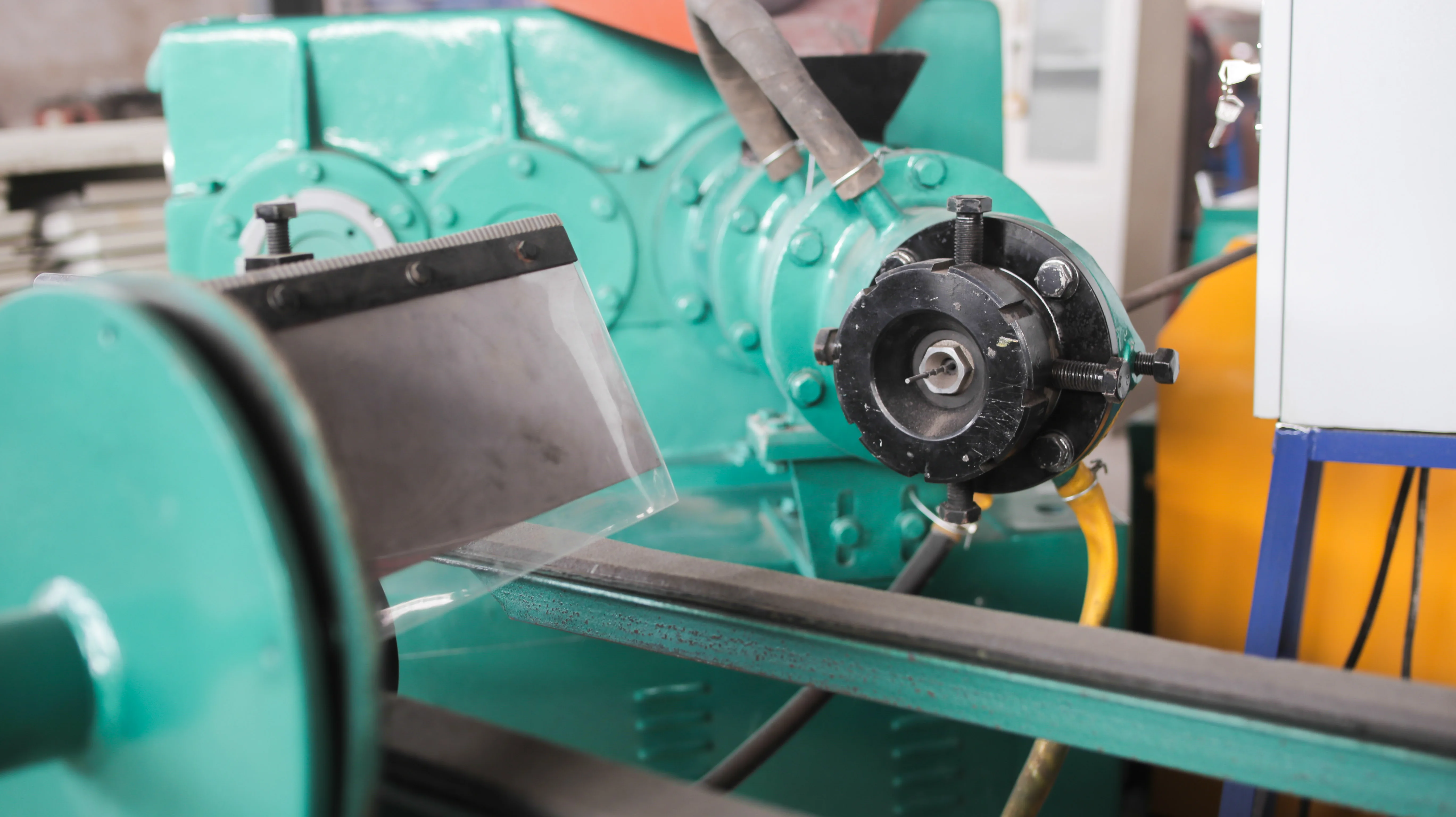

Descaling machine |

Remove the dust from the wire. |

2 |

Tip roller |

Sharpen the tip of wire. |

3 |

Butt-welding machine |

To weld the wire tips when 1 roll is finished. |

4 |

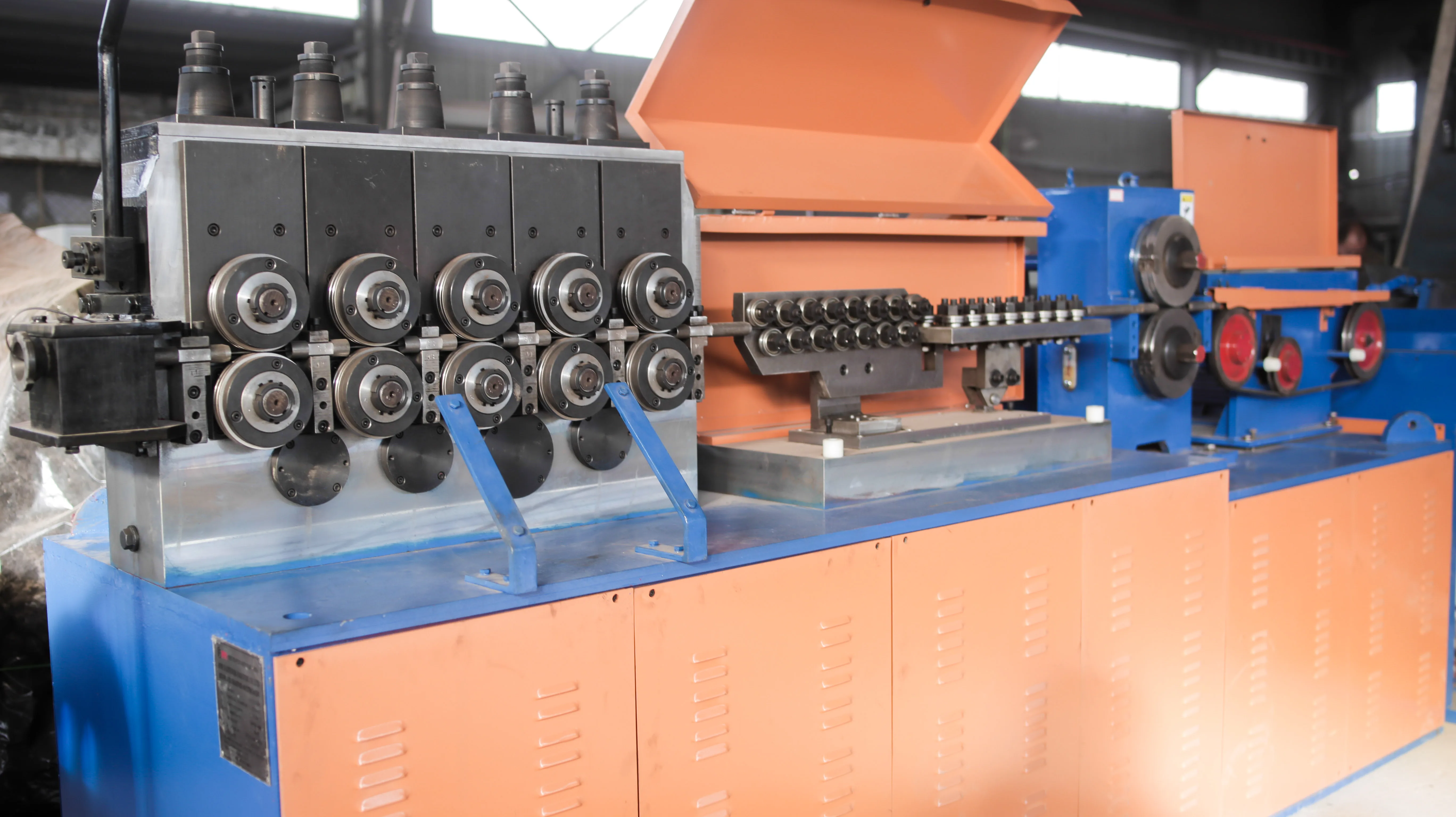

Wire drawing machine |

To draw the wire into diameter needed. |

5 |

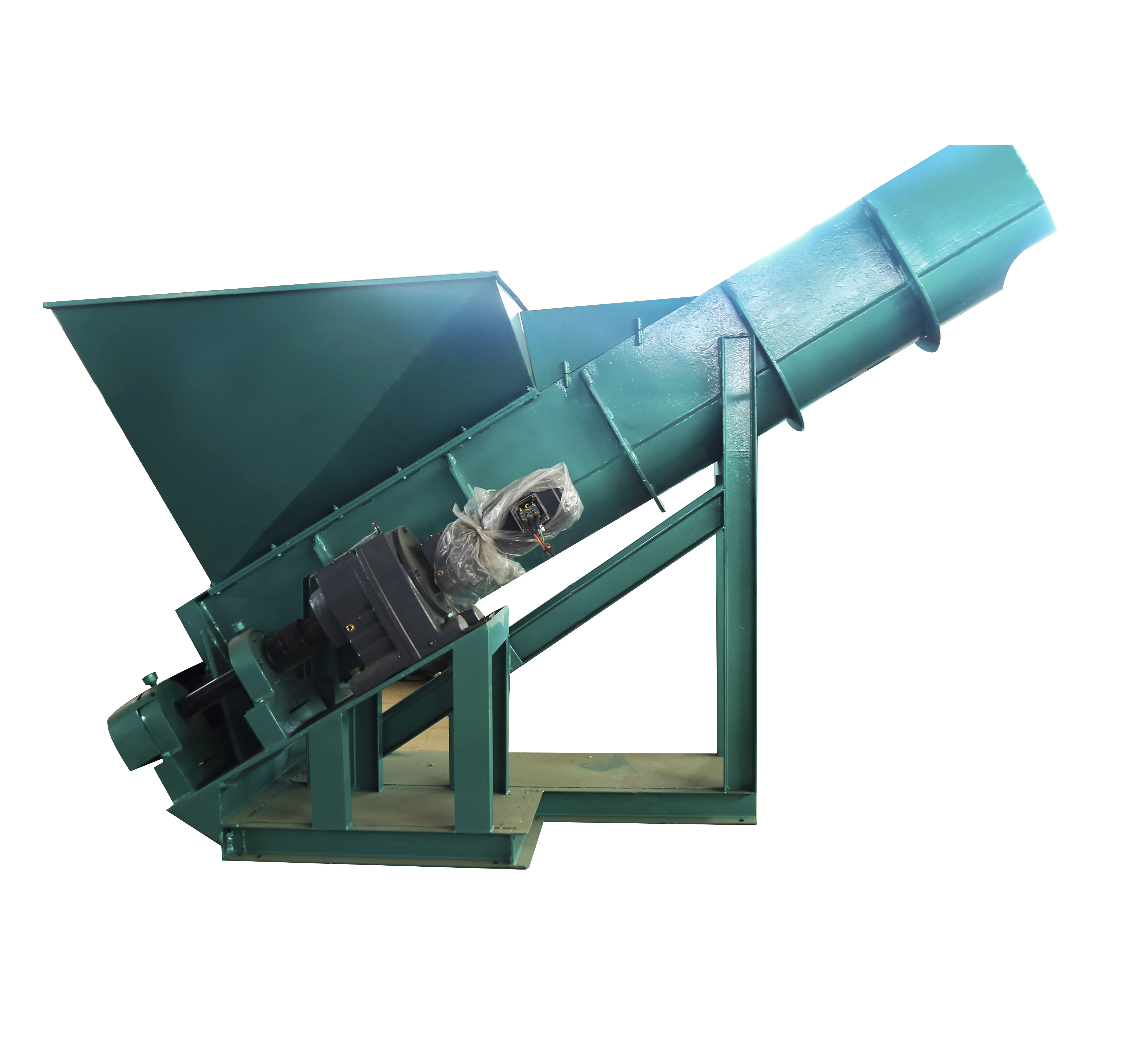

Single arm crane |

To lift the wires. |

6 |

Wire cutting machine |

To cut wire into size. |

7 |

Mixing Machines Double "S" Type |

Mix the powder for coating. |

8 |

Silicate Mixer |

Silicate stirring barrel is special for stirring liquid silicate. |

8 |

Wire-feed machine |

Wire supply. |

9 |

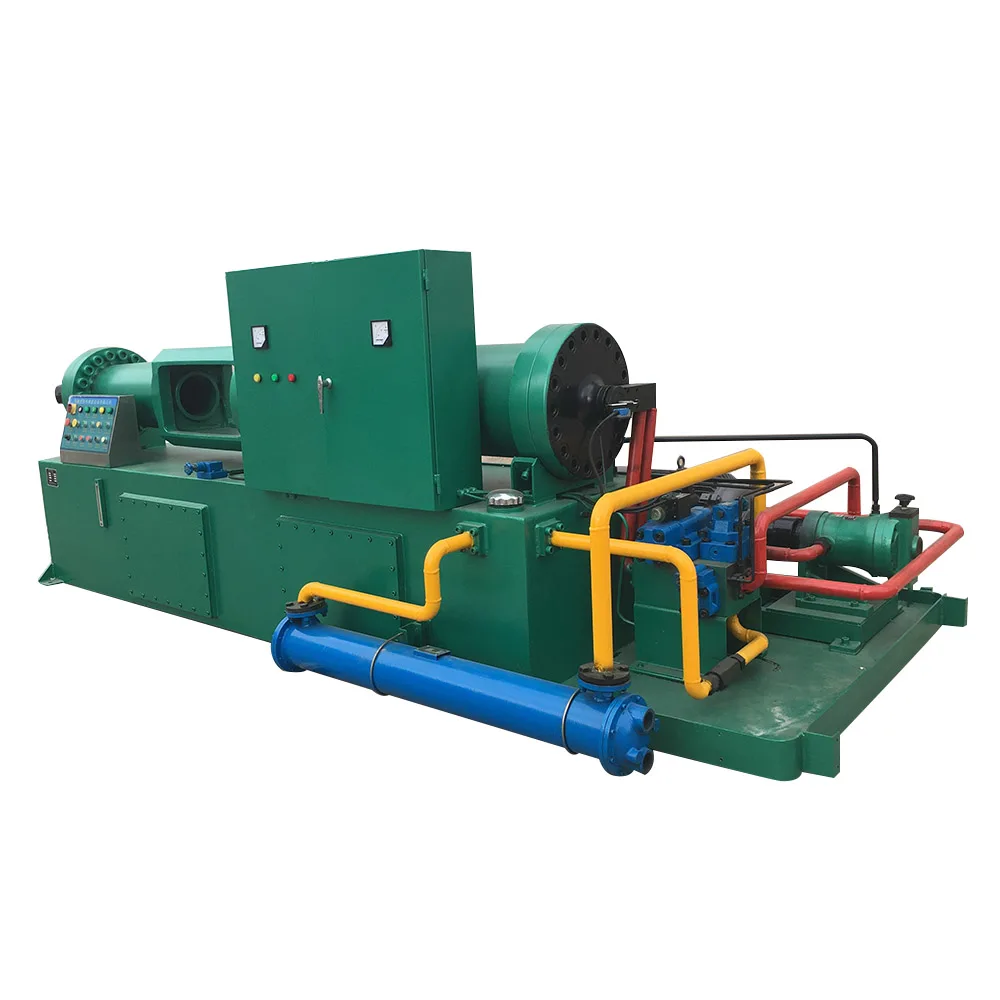

Hydraulic powder coating machine |

Coat the mixed powder onto the wire. |

10 |

Head-Tail Grinder machine |

To grind the head and tail into standard shape. |

11 |

Electrode eccentric measuring Instrument |

Eccentric checking. |

12 |

Control panel for spiral line |

Main control of electricity. |

13 |

Auxiliary line machine |

Internal conveying. |

14 |

Box type hot air circulation drying furnace(electricity) |

Drying the coating on the core. |

15 |

Words printer |

Printing dates or brand name. |

16 |

Shrink packaging machine |

Plastic packing. |

17 |

Strapping machine |

Wrapping. |

18 |

Reclaiming machine |

Peel the coating off. |

19 |

Straightening machine |

Straighten the wire. |

20 |

Vibrating screen |

To filter the recycled coating. |

EN

EN