Product Description

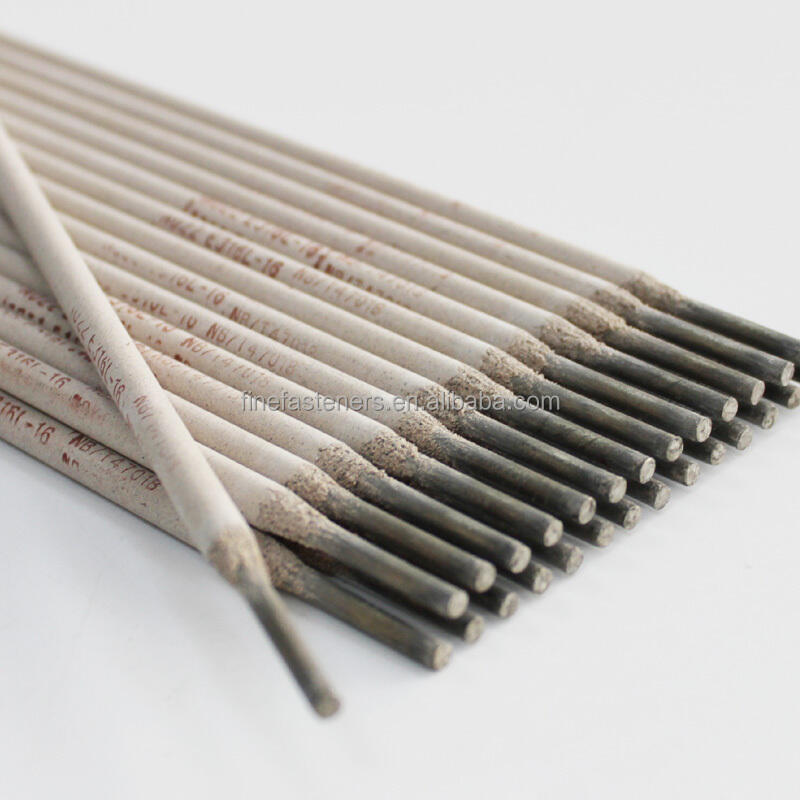

Presenting the Helix Welding Electrode Manufacturing Line Spiral Kind E6013, joyfully crafted by FFI. This item that is high-grade designed and also materials to ensure to the customer that every welding tasks are made with precision and also reduce failure also cost doing the project, production it the selection that is better for expert welders and also DIY fanatics. It doesn't mean that you are a DIY Fanatics, you are not allowed to use this product. DIY fanatics can also use this as their primary tools in doing the task.

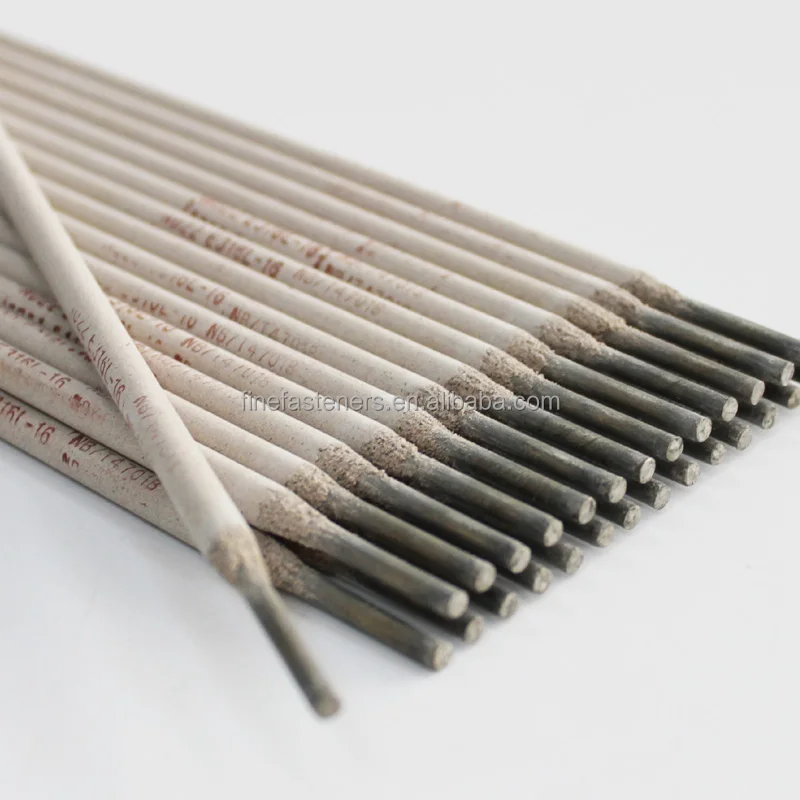

The Helix Welding Electrode Manufacturing Line Spiral Kind E6013 is just an item that is revolutionary is quite an easy task to take advantage of and likewise provides effectiveness that is optimal. Its kind that is ingenious that spiral makes welding easier as well as not as taxing, guaranteeing that you total your jobs quicker. The welding electrodes manufactured by this equipment are of impressive quality that is top may also be perfect for different welding applications.

This item is easy to operate, production it suitable for everyone, from novice to welders being seasoned. The production procedure is automated, eventually causing quality that is constant is top, hence decreasing the possibility of electrode failing while welding. Likewise, applying this gear, you are able to bid farewell towards the working job that is overwhelming of electrodes by hand, significantly decreasing work expenses as well as in addition boosting the rate of manufacturing.

The Helix Welding Electrode Manufacturing Line Spiral Kind E6013 had been built to basically feel absolutely effective, which makes it a choice that is production that is great is industrial scale. The gear's innovative contemporary technologies assist to make sure that the welding electrodes made have now been normal in proportions and likewise duration, supplying accuracy that is completely excellent welding programs. The generation which will definitely be spiral make it well their electrode production details, supplying much more strength and also resistance to damages, that means it's well suited for hefty welding functions.

This method is actually produced utilizing premier materials, production toughness that is longevity that is particular as well as in addition uniformity. The gadget often made with protection in your opinions, with precaution such a circumstance end that is instant.

choice

also, it secure being suitable in any types of job. Their solid characteristics makes it more durable and also design triggers it is best for made usage of in sturdy scenarios like doing heavy task in your area, suffering welding that is absolutely solid.

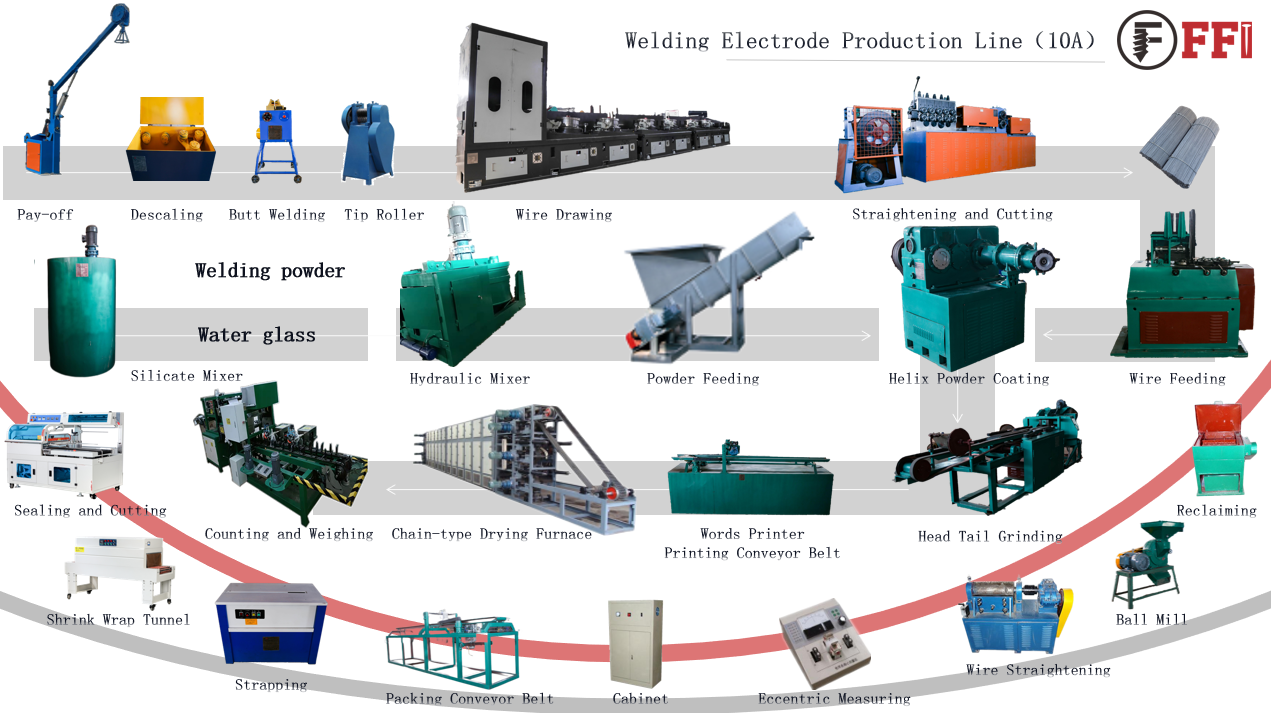

No. | Equipment | Function |

1 | Descaling machine | Remove the dust from the wire. |

2 | Tip roller | Sharpen the tip of wire. |

3 | Butt-welding machine | To weld the wire tips when 1 roll is finished. |

4 | Wire drawing machine | To draw the wire into diameter needed. |

5 | Single arm crane | To lift the wires. |

6 | Wire cutting machine | To cut wire into size. |

7 | Mixing Machines Double "S" Type | Mix the powder for coating. |

8 | Silicate Mixer | Silicate stirring barrel is special for stirring liquid silicate. |

8 | Wire-feed machine | Wire supply. |

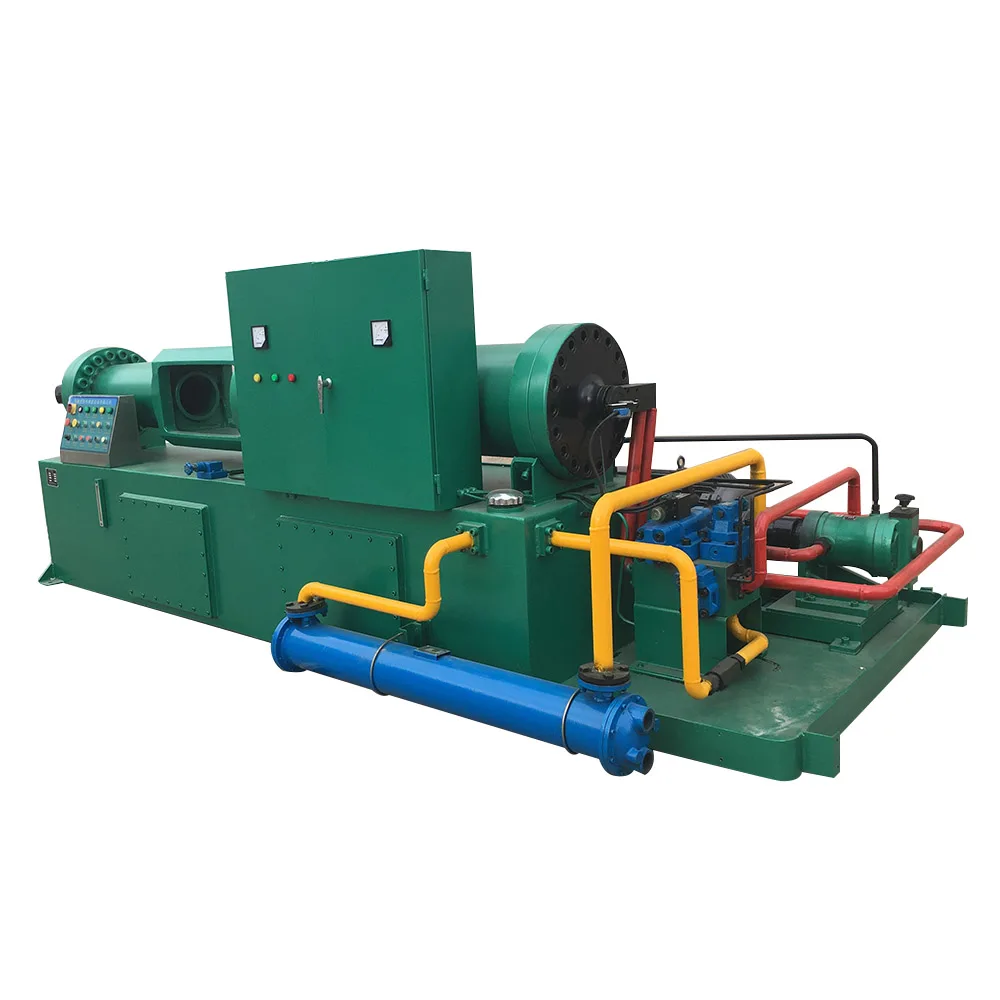

9 | Helix powder coating machine | Coat the mixed powder onto the wire. |

10 | Head-Tail Grinder machine | To grind the head and tail into standard shape. |

11 | Electrode eccentric measuring Instrument | Eccentric checking. |

12 | Control panel for spiral line | Main control of electricity. |

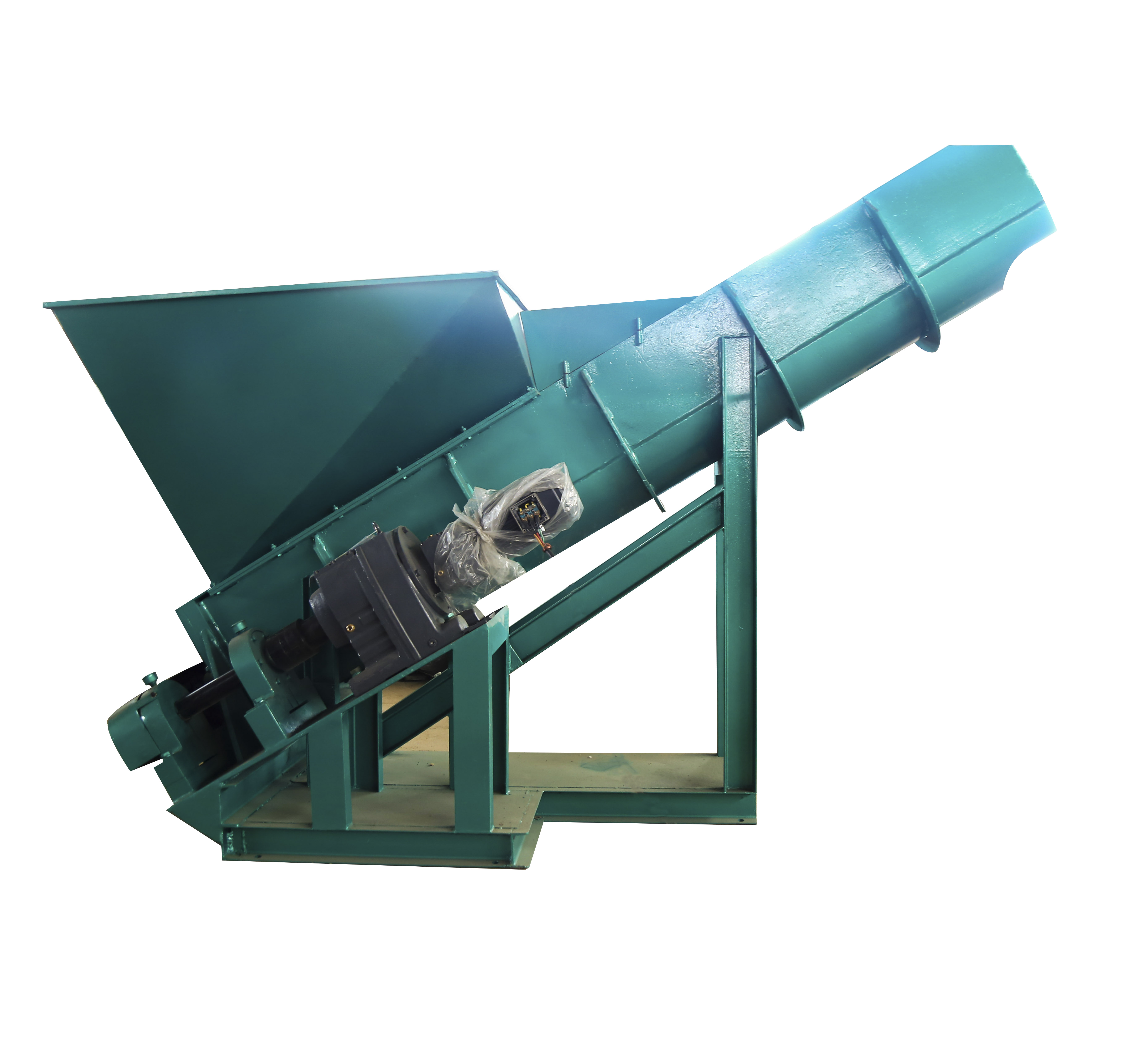

13 | Auxiliary line machine | Internal conveying. |

14 | Box type hot air circulation drying furnace(electricity) | Drying the coating on the core. |

15 | Words printer | Printing dates or brand name. |

16 | Shrink packaging machine | Plastic packing. |

17 | Strapping machine | Wrapping. |

18 | Reclaiming machine | Peel the coating off. |

19 | Straightening machine | Straighten the wire. |

20 | Vibrating screen | To filter the recycled coating. |

EN

EN