Welding electrode making machine/Welding electrode production line/welding rod manufacturer plant

Product Description

Welding Electrodes Production Line Plant

Product Overview

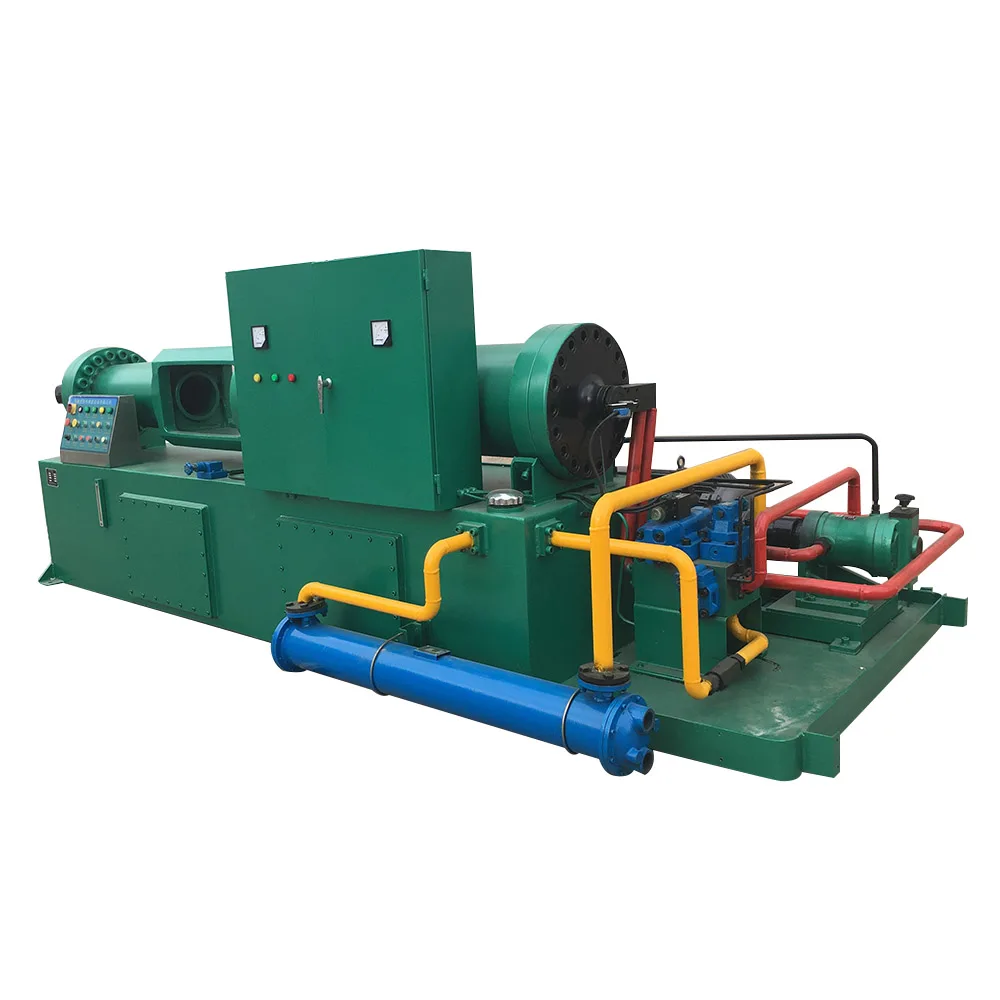

The output of 135A helical coated electrode production line is usually about 1 ton per hour.It has simple structure, easy manufacturing, convenient maintenance, no need to stop charging, can continuous production, so it has high production efficiency, and make the coating thickness uniformity, smooth, dense, the advantages of stable quality, also can make the pressure of electrode coating, transfer, grinding head, grinding, printing, drying and packaging process to realize the automatic intelligent or completely, is mainly in the production of the electrode production methods.

Design specification

1. Output: 3 to 5 tons, 6 to 8 tons, 8 to 10tons per 8hour(take the Φ3.2mm’s welding electrode for example)

2. Delivery time: 60day

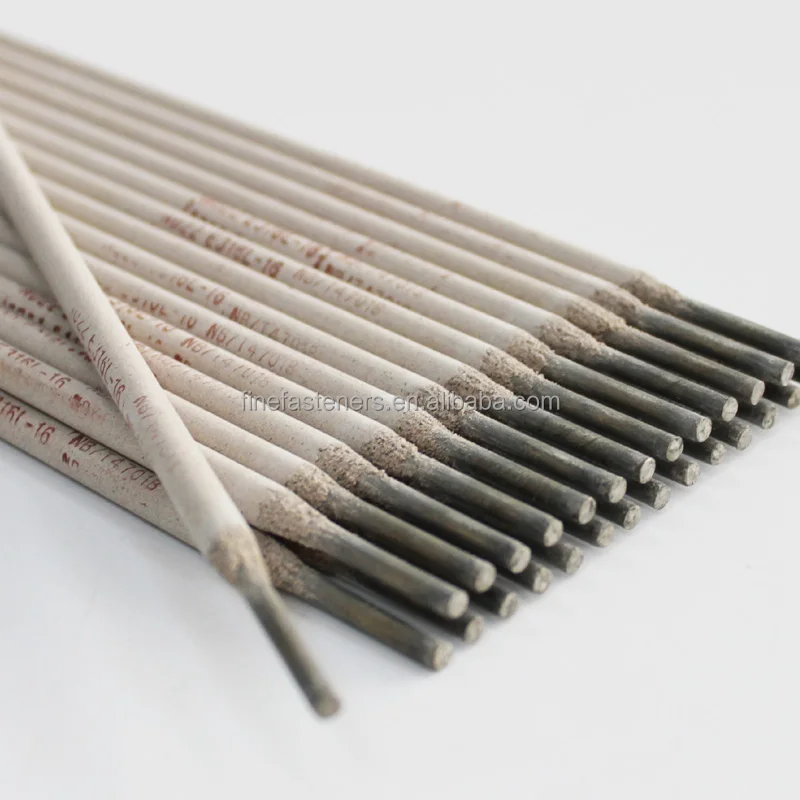

3. Size of the production: Φ2.5mm, Φ3.2mm, Φ4.0mm, Φ5.0mm

4. Production electrode type: ordinary carbon steel electrode AWS E6013

5. Workers: 8-10 people; assistant personnel:2-3 people

6. Transportation:three 40 feet containers

7. Price excluding equipment wearing parts

8. HS CODE:84633000

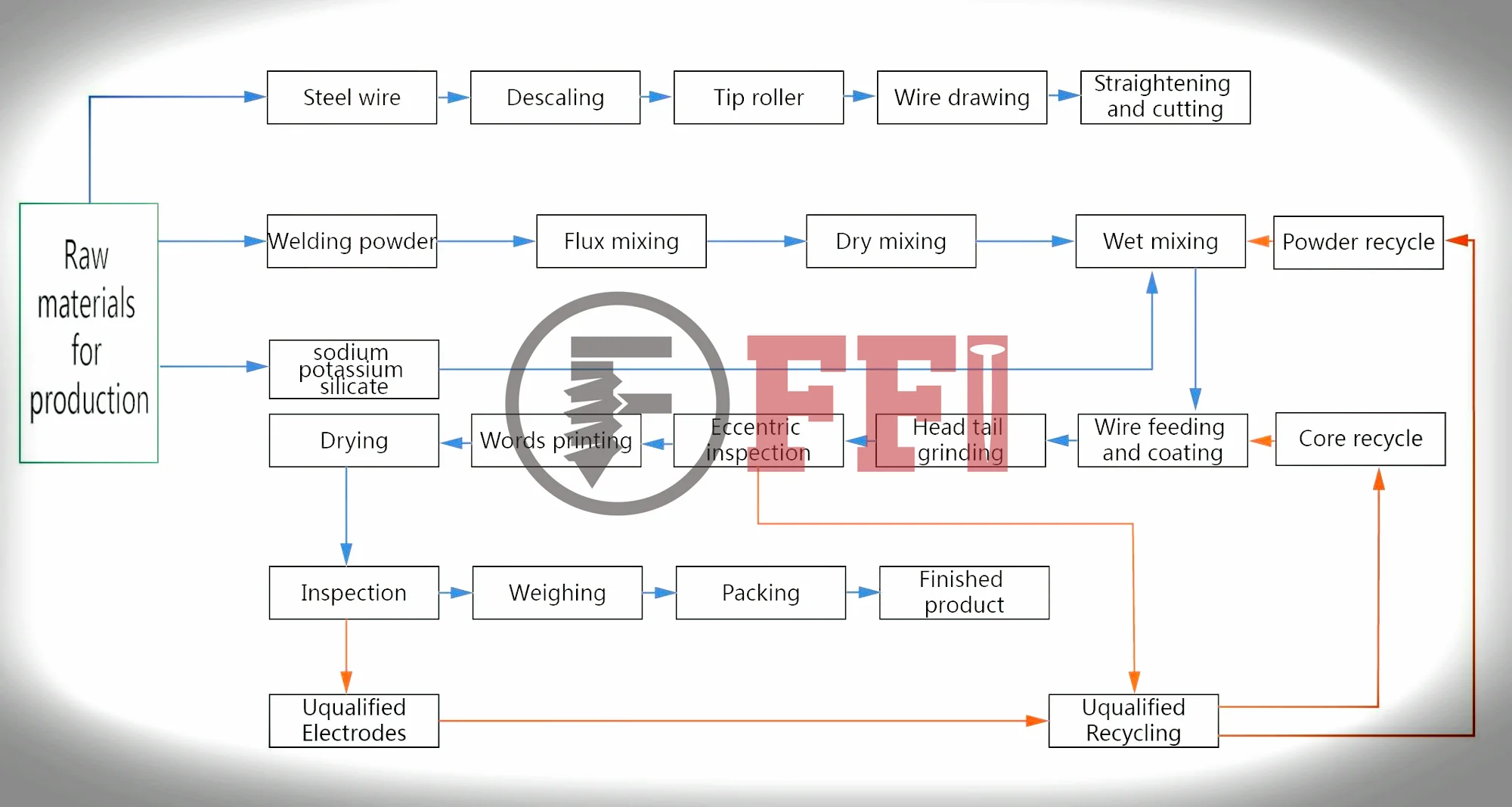

Flow Chart:

PRODUCT SPECIFICATIONS

No. |

Equipment |

Function |

1 |

Descaling machine |

Remove the dust from the wire. |

2 |

Tip roller |

Sharpen the tip of wire. |

3 |

Butt-welding machine |

To weld the wire tips when 1 roll is finished. |

4 |

Wire drawing machine |

To draw the wire into diameter needed. |

5 |

Single arm crane |

To lift the wires. |

6 |

Wire cutting machine |

To cut wire into size. |

7 |

Powder mixer |

Mix the powder for coating. |

8 |

Wire-feed machine |

Wire supply. |

9 |

Helix powder coating machine |

Coat the mixed powder onto the wire. |

10 |

Head-Tail Grinder machine |

To grind the head and tail into standard shape. |

11 |

Electrode eccentric measuring Instrument |

Eccentric checking. |

12 |

Control panel for spiral line |

Main control of electricity. |

13 |

Auxiliary line machine |

Internal conveying. |

14 |

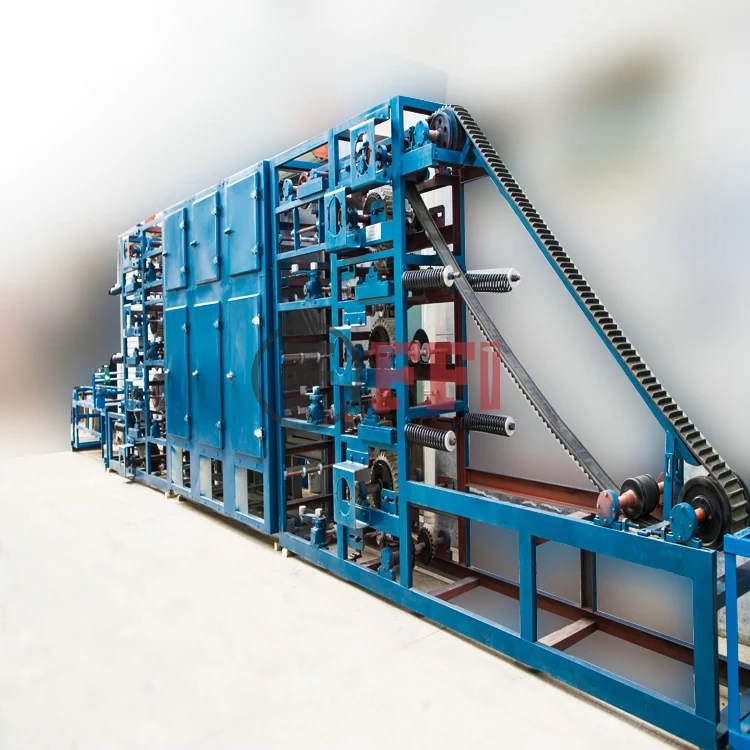

Box type hot air circulation drying furnace(electricity) |

Drying the coating on the core. |

15 |

Words printer |

Printing dates or brand name. |

16 |

Shrink packaging machine |

Plastic packing. |

17 |

Strapping machine |

Wrapping. |

18 |

Reclaiming machine |

Peel the coating off. |

19 |

Straightening machine |

Straighten the wire. |

20 |

Vibrating screen |

To filter the recycled coating. |

Company Profile

Fine Fasteners Industry Co.,Ltd (FFI) has been a super manufacturer and exporter of the spiral coated electrode production line series, hydraulic coated mechanical and electrical welding rod production line series has excellent manufacturing equipment, advanced production technology, product quality is stable and high production efficiency, high speed, and make the coating thickness uniformity, smooth, dense, the advantages of stable quality,

also can make the pressure of electrode coating, transfer, grinding head grinding tail, printing, drying and packing process to realize full mechanization and automation, such as is currently the major electrode production enterprise much-loved electrode device. Our company also supplies various types, specifications of welding rod production raw materials, to provide customers with one-stop service.Up to now our customers are spread in Europe, Asia, Africa, South Africa, Middle East and other countries & regions. With our superior quality, competitive price and professional service, we have gained great approval and satisfaction from customers globally.

We will continuously stick to the core principle of “Fine person, Fine product and Fine service” and offer the best equipment for customers through never-ending research and development. We are sincerely looking forward to working together with you to create a glorious future.

also can make the pressure of electrode coating, transfer, grinding head grinding tail, printing, drying and packing process to realize full mechanization and automation, such as is currently the major electrode production enterprise much-loved electrode device. Our company also supplies various types, specifications of welding rod production raw materials, to provide customers with one-stop service.Up to now our customers are spread in Europe, Asia, Africa, South Africa, Middle East and other countries & regions. With our superior quality, competitive price and professional service, we have gained great approval and satisfaction from customers globally.

We will continuously stick to the core principle of “Fine person, Fine product and Fine service” and offer the best equipment for customers through never-ending research and development. We are sincerely looking forward to working together with you to create a glorious future.

Why Choose Us

1 Our company has professional installation & commissioning teams, we will install and debug the production

line at the customers’ place until the equipment produces qualified products.

2 We supply spare parts all the year round. The guarantee of equipment is one year.

3 We are responsible for the technical consultation and service all the year around and help to solve all kinds

of technical problems at any time.

4 We will help customers do the consignment and the relevant procedure for import and export.

5 Our company supply the information of the seller for all kinds of raw materials and relevant information for free.

line at the customers’ place until the equipment produces qualified products.

2 We supply spare parts all the year round. The guarantee of equipment is one year.

3 We are responsible for the technical consultation and service all the year around and help to solve all kinds

of technical problems at any time.

4 We will help customers do the consignment and the relevant procedure for import and export.

5 Our company supply the information of the seller for all kinds of raw materials and relevant information for free.

Packing And Delivery

Contact Us

FINE FASTENERS INDUSTRIES CO.,LTD.

Grace Lu (Sales Manager)

TEL: +86-551-82620162

FAX: +86-551-82620162

Mobile/Whatsapp/Skype: +8617318599338

Email: sales(at)finefasteners.com

Web: www.finefasteners.com

TEL: +86-551-82620162

FAX: +86-551-82620162

Mobile/Whatsapp/Skype: +8617318599338

Email: sales(at)finefasteners.com

Web: www.finefasteners.com

EN

EN