Whatsapp: +8613731996862

Email: ariel(at)finefasteners.com

Website: www.finefasteners.com

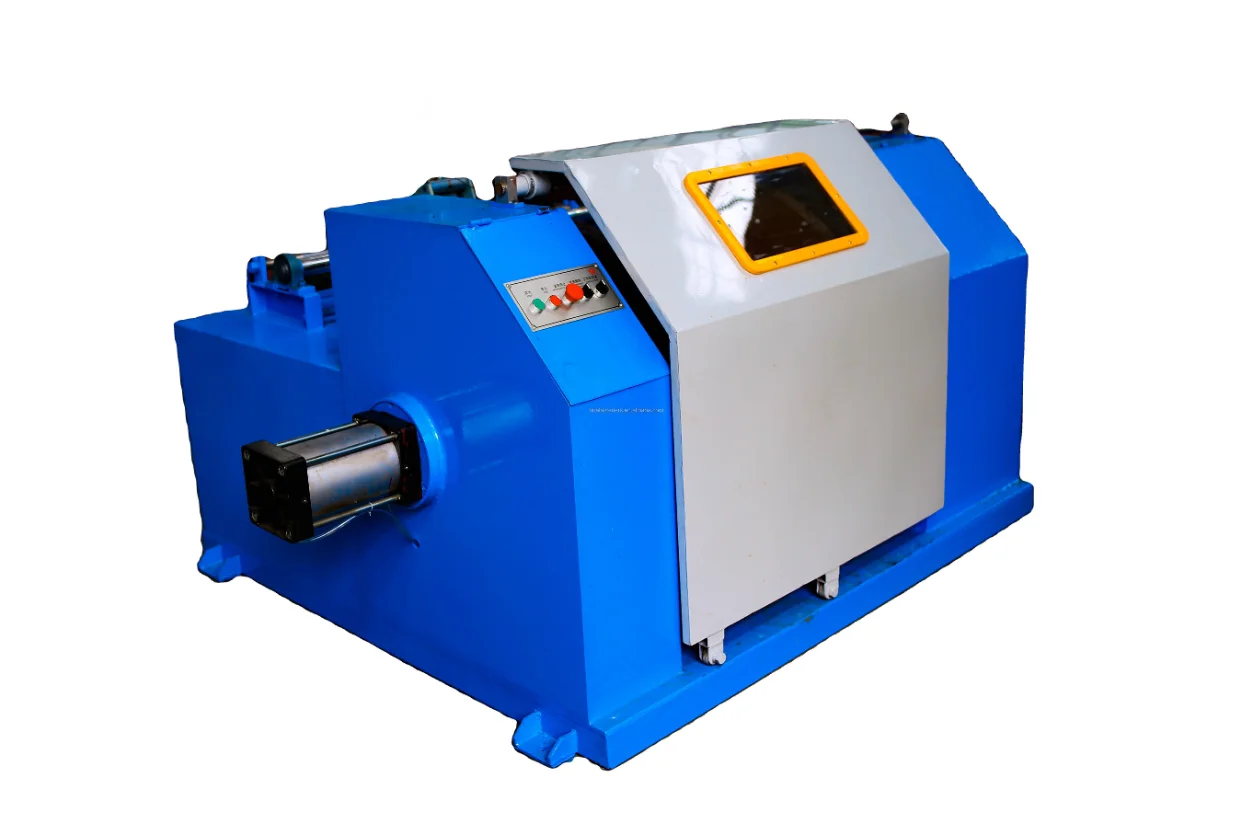

Type |

300 |

350 |

400 |

450 |

500 |

560 |

600 |

700 |

800 |

||||||||

Material Intensity |

≤1250Mpa |

||||||||||||||||

Drawing Passes |

2 ~ 11 |

2 ~ 11 |

2 ~ 11 |

2 ~ 12 |

2 ~ 12 |

2 ~ 12 |

2 ~ 12 |

2 ~ 9 |

2 ~ 9 |

||||||||

Max. Dia. Of Inlet Wire |

2.8mm |

3.5mm |

4.2mm |

50mm |

5.5mm |

6.5mm |

8mm |

10mm |

12.7mm |

||||||||

Min. Dia. Of Outlet Wire |

0.5mm |

0.6mm |

0.75mm |

1.0mm |

1.2mm |

1.4mm |

1.6mm |

2.2mm |

2.6mm |

||||||||

Max. Speed Of Drawing |

~25m/s |

~20m/s |

~20m/s |

~16m/s |

~15m/s |

~15m/s |

~12m/s |

~ 12m/s |

~ 8m/s |

||||||||

Drawing Power |

7.5~18.5kw |

11~22kw |

11~30kw |

15~37kw |

22~45kw |

22~55kw |

30~75kw |

45~90kw |

55~110kw |

||||||||

Name |

Model |

Range of Dia. |

Discharging Machine |

||

Pointing Machine |

FFI-F-96 |

6.5-1.5mm |

Pointing Machine |

FFI-F-80 |

3.5-1.0mm |

Butt-Welding Machine |

FFI-UN-10 |

8--2mm |

Butt-Welding Machine |

FFI-UN-3 |

6.5-1.5mm |

Butt-Welding Machine |

FFI-UN-1 |

3.5-1.0mm |

Automatic Discharging Machine |

FFI-XB-600 |

capacity 800kg |

Automatic Discharging Machine |

FFI-XB-360 |

capacity 400kg |

I Type Spool Reeling Machine |

FFI-SG-800 |

capacity 800kg |

I Type Spool Reeling Machine |

FFI-SG-630 |

capacity 500kg |

Descaling Machine |

FFI-SW650 |

|

Motorless Descaling Machine |

with steel brush |

|

Well Type Furnace |

FFI-RJ-90-9 |

Straight line wire drawing machine |

||||

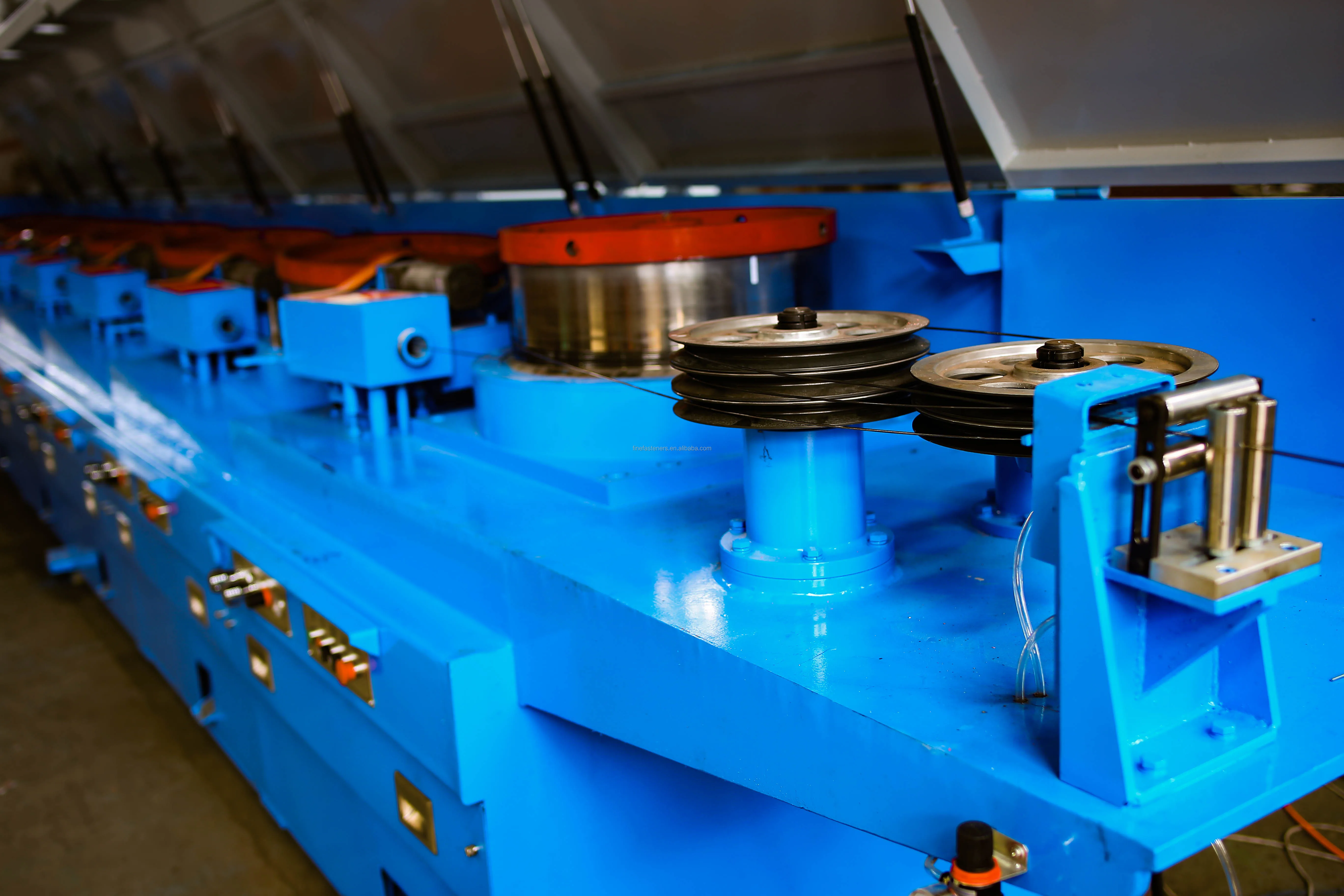

1 |

Wire drawing drum material |

Cast steel, tungsten coating and surfacing, HRC60. Roughness is less than 0.8umm |

||

2 |

Drum cooling |

1. Drum inside cooling: drum’s inner wall has 3 water channels which displayed in 120 degrees direction by water spraying. 2. Drum external cooling: the ventilation pipe below the outside of the drum uses 360 degrees of forced air cooling on the surface of the drum and wire to lower the surface temperature of the reel below 80 degrees |

||

3 |

Die box cooling way |

The drawing die is cooled by using direct water inlet and outlet water, and the cooling effect is especially good |

||

4 |

Tension machine |

Built-in |

||

5 |

Main frame |

Steel plate and square tube welding |

||

6 |

Safety device |

Safety protection cover, broken line stop test |

||

7 |

Vacuum design |

Vacuum cleaning hole |

||

8 |

Lighting |

Each machine is equipped with separate lighting |

||

9 |

Parking brake |

Pneumatic brake |

||

10 |

Electric cabinet |

Protection level IP54 |

||

11 |

Electrical system |

Machine distribution structure, PROFIBUS-DP field bus control |

||

12 |

Energy consumption |

Monitoring is equipped with electricity meter |

||

13 |

PLC |

HUICHUAN (Inovance) brand |

||

14 |

Touch screen |

HUICHUAN 10inch screen |

||

15 |

Frequency motor brand |

Fangda |

||

16 |

Low voltage apparatus |

Zhengtai |

||

17 |

Inverter |

HUICHUAN (Inovance) brand |

||

18 |

Sensor |

OMRON |

||

19 |

Field cable supply |

The dedicated control line is provided by the seller, and other control cables and power cables are provided by the buyer |

||