Product Description

If you should be buying a welding device that is able to bond materials with a high precision and effectiveness, further look no than FFI CO2 Wire Making Welding Machine. This device makes use of CO2 due to the fact welding fuel, developing a very good, top-quality bond between metals.

The FFI CO2 Wire Making Welding Machine is perfect for those inside the manufacturing, construction, and automotive industries who need to make quick and welds which are accurate. The unit was created to make use of a number of materials, including alloy this is certainly low, stainless steel, and aluminum. It might also manage an array of welding wire diameters, which makes it versatile enough for almost any job.

The FFI CO2 Wire Making Welding Machine is user friendly, which makes it perfect for both welders that are skilled those not used to the industry. The device features a easy, intuitive user interface which allows users to change the welding voltage and wire feed speed as needed. This degree of control really helps to make certain that welds are of constant quality, regardless of the operator's skill level.

One of the most significant standout highlights of the FFI CO2 Wire Making Welding Machine is its ability to reduce spatter during welding. Spatter does occur when tiny droplets of metal are expelled during welding, which could develop a messy, unpleasant finish. The FFI device minimizes spatter, causing clean, exact welds everytime.

The product even offers a wide range of security features built in, including protection this is certainly overheat a crisis end switch. These safety features make sure operators could work with full confidence, knowing that they've been protected in the event that is unlikely of malfunction.

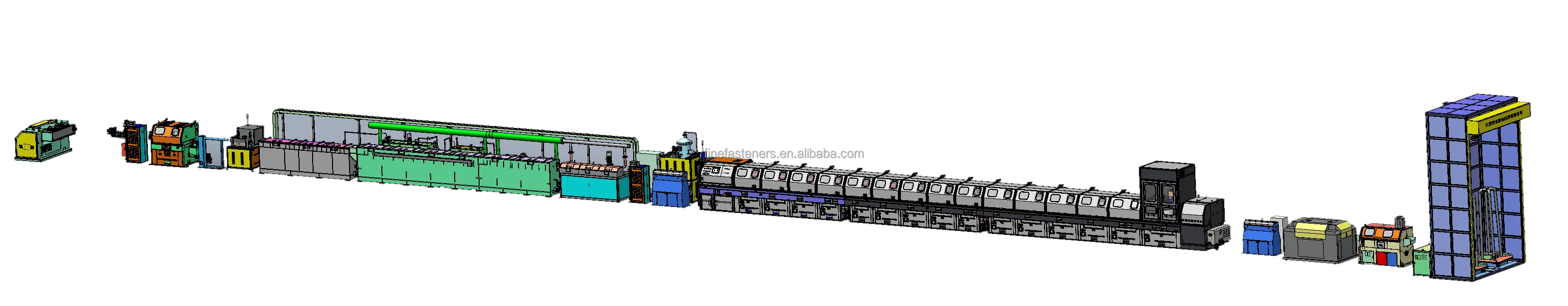

HD-20 welding wire production line is widely applied to manufacture MIG/CO2/SAW welding wires.

Welding wire type Wire diameter(mm) MIG/CO2 solid wire 0.8, 1.0,1.2,1.6 SAW solid wire 2.0, 2.5, 3.2, 4.0, 5.0

II. Process:

1. Wire rod pre-treatment line: remove the dirty from the wire surface

2. Wire drawing line: drawing the wire from large diameter to small diameter.

3. Copper coating line: Pay off machine+ constant tension adjusting+wire supporting wheel and wire turning wheel + big turning

device + mechanical degrease+ electrolytic acid pickling(rough cleaning )+electrolytic alkaline cleaning(fine cleaning)+ hot water

wash+ former neutralize+electrolytic acid pickling — cool water clean+ activate acid cleaning + chemical copper coating+ cool

water clean+Neutralized + hot water wash+ dry+ wire press fix wheel(roller) + big turning device + polishing drawing +take up

machine

4. Laye winding machine: respooling the welding wire from the steel spool onto small plastic bobbin.

5. Drum packing machine: coiling the welding wire into a drum.

Product Name |

CO2 GAS MIG WELDING WIRE PRODUCTION LINE |

Wire Diameter |

6.5mm,5.5mm |

Brand Name |

FFI |

Year |

2022 |

Model Number |

FFI--XXCO2-6508B |

Dimension(L*W*H) |

21.5*1.450*1.6m |

Weight |

31280KG |

Place of Origin |

China |

Anhui |

|

Automatic Grade |

Semi-automatic |

Voltage |

380V or Customize |

Power |

3000W |

Machinery Capacity |

Production capacity: 0.8mm--6.5t /1.0mm-10t/1.2mm-17t (20 working hours Max one day) |

Key Machines |

Metal Electroplating Machinery, Metal Polishing Machine, Metal Sheet Processing Machine, Lathe |

Product Type |

ER70S-6 Welding wire |

Finished Product |

15kg pallet weldingwire |

Usage |

Vehicles Bridge-engineering Machine-engineering Steel structures Ship manufacture Trade container |

Type |

Gas Shield Welding Wire |

After Warranty Service |

Online support, Field installation, commissioning and training |

Raw material |

Carbon Steel |

Capacity |

0.8mm--6.5t /1.0mm-10t/1.2mm-17t |

Feature |

Excellent Welding Performance |

Advantage |

Professional Manufacturer |

Certification |

SGS CE PATENT |

Color |

Customized Color |

EN

EN