Product Description

The CO2 Gas Mig Welding Cable Manufacturing Line by FFI is just a advanced manufacturer that makes use of specific in addition to efficiency that is dependable production it the service that would work welders preparing to simplify their procedures. This item was intended to create quality that is cables which can be top are completely matched for many commercial applications, composed of yet not restricted to shipbuilding, aerospace, along side automobile.

This is often the truth is cable televisions is its level that is innovation that is most of utilizing gases that is CO2 enhance the welding treatments to the center stressing the CO2 Gas Mig Welding manufacturing. This gasoline offers securites this will certainly be many certainly excellent the welding treatment, directing free from the introduction of unwelcome oxides which will definitely harm the weld. These gadgets has really the ability to create superior-quality welding cable televisions which really are a complete much more resilient along with reputable when put next with various other selections using this gases.

Manufacturing fix for this CO2 Gas Mig Welding manufacturing this is certainly really cable is effortless nevertheless really dependable. It provides steps which are really a range that is wide of as for example as an example wire consuming, fixing the alignment of, reducing, in addition to spooling, a lot of they are finished immediately as a result of the merchandise. This means welders will positively assistance save a quantity it's in truth significant of in addition to power that is billed this product, because they no real longer that is much to carries out these tasks that may be tiresome.

Another property that is necessary's advantageous of CO2 Gas Mig Welding manufacturing this can be in reality cable televisions is its freedom. This could easily take truth big of programs having really the ability to generates cable that is welding employing a more substantial differs of many sizes, composed of 0.8mm to 1.6mm, production it perfect a range. Furthermore, these devices could likewise takes care that is appropriate of types product and solutions, such as for instance stainless-steel along with carbons metal, manufacturing versatility this is unquestionably is certainly welders being plainly optimal.

The CO2 Gas Mig Welding Manufacturing that is cable Line incomparable in regards to toughness in addition to integrity. Its strong building and construction guarantees that it could stand as much as also one of the very requiring of commercial atmospheres, while its progressed innovation guarantees so it could frequently produce top quality welding cables that fulfill the strictest good quality criteria.

General, the CO2 Gas Mig Welding Cable Manufacturing Line by FFI is an excellent investment that is financial welders likely to enhance their efficiency along side performance, while likewise making specific the product quality that is most beneficial of function. This item makes certain to conferences the requirements of additionally one of the very needed of welding procedures along with its progressed innovation, versatililty efficiency, also resilient building and construction.

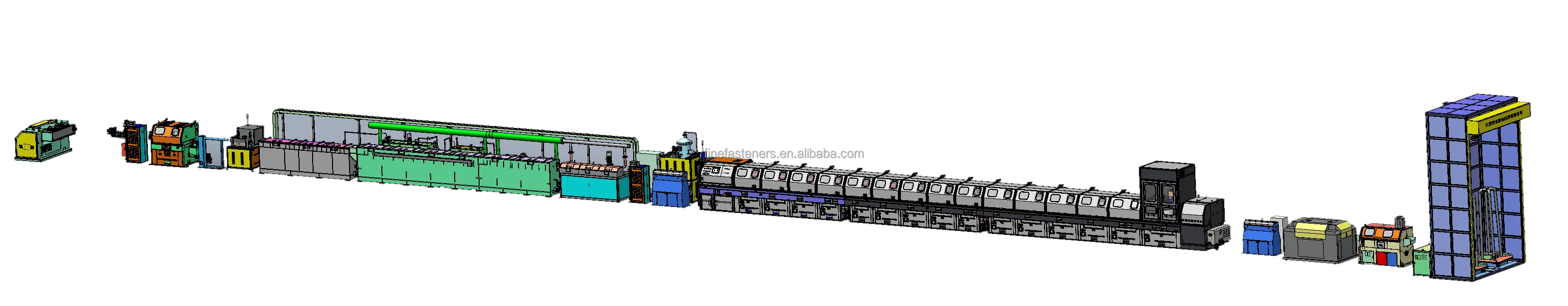

I. Application range:

HD-20 welding wire production line is widely applied to manufacture MIG/CO2/SAW welding wires.

Welding wire type Wire diameter(mm) MIG/CO2 solid wire 0.8, 1.0,1.2,1.6 SAW solid wire 2.0, 2.5, 3.2, 4.0, 5.0

II. Process:

1. Wire rod pre-treatment line: remove the dirty from the wire surface

2. Wire drawing line: drawing the wire from large diameter to small diameter.

3. Copper coating line: Pay off machine+ constant tension adjusting+wire supporting wheel and wire turning wheel + big turning

device + mechanical degrease+ electrolytic acid pickling(rough cleaning )+electrolytic alkaline cleaning(fine cleaning)+ hot water

wash+ former neutralize+electrolytic acid pickling — cool water clean+ activate acid cleaning + chemical copper coating+ cool

water clean+Neutralized + hot water wash+ dry+ wire press fix wheel(roller) + big turning device + polishing drawing +take up

machine

4. Laye winding machine: respooling the welding wire from the steel spool onto small plastic bobbin.

5. Drum packing machine: coiling the welding wire into a drum.

Product Name |

CO2 GAS MIG WELDING WIRE PRODUCTION LINE |

Wire Diameter |

6.5mm,5.5mm |

Brand Name |

FFI |

Year |

2022 |

Model Number |

FFI--XXCO2-6508B |

Dimension(L*W*H) |

21.5*1.450*1.6m |

Weight |

31280KG |

Place of Origin |

China |

Anhui |

|

Automatic Grade |

Semi-automatic |

Voltage |

380V or Customize |

Power |

3000W |

Machinery Capacity |

Production capacity: 0.8mm--6.5t /1.0mm-10t/1.2mm-17t (20 working hours Max one day) |

Key Machines |

Metal Electroplating Machinery, Metal Polishing Machine, Metal Sheet Processing Machine, Lathe |

Product Type |

ER70S-6 Welding wire |

Finished Product |

15kg pallet weldingwire |

Usage |

Vehicles Bridge-engineering Machine-engineering Steel structures Ship manufacture Trade container |

Type |

Gas Shield Welding Wire |

After Warranty Service |

Online support, Field installation, commissioning and training |

Raw material |

Carbon Steel |

Capacity |

0.8mm--6.5t /1.0mm-10t/1.2mm-17t |

Feature |

Excellent Welding Performance |

Advantage |

Professional Manufacturer |

Certification |

SGS CE PATENT |

Color |

Customized Color |

We are based in Anhui, China, start from 2020,sell to Mid East(15.00%),Africa(12.00%),Eastern Europe(11.00%),Western Europe(9.00%),South America(8.00%),Southeast Asia(8.00%),Central America(8.00%),Southern Europe(8.00%),Eastern Asia(6.00%),Northern Europe(6.00%),South Asia(6.00%),North America(3.00%). There are total about 11-50 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. What can you buy from us?

Nail Making Machine,Annealed Black Wire Twisting Machine,Wire Drawing Machine,Coil Nail Making Machine,Welding Electrodes Making Machine

4. Why should you buy from us not from other suppliers?

Fine Fasteners Industry Co.,Ltd has been a super manufacturer and exporter of welding wire for coil nail and supply chain for all kinds of wires, nails and the related machines such as all types of wire drawing machine, nail making machine^

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

EN

EN