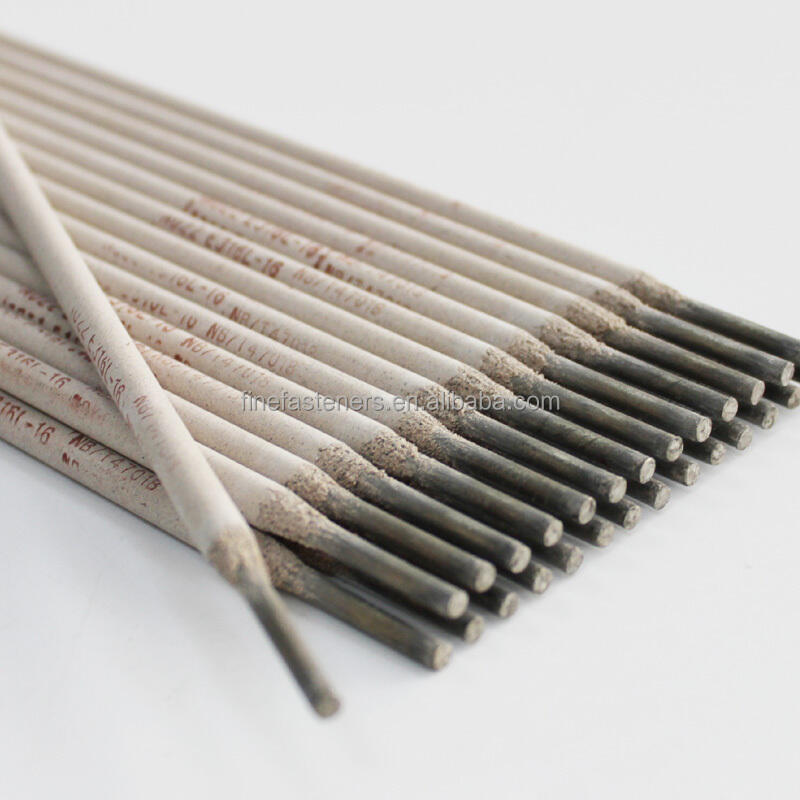

Product Description

The FFI Hydraulic Welding Electrode Production Line is a must-have for virtually any ongoing business this is really wanting to create welding that is high-quality quickly and efficiently. This production line can create electrodes faster than any other production line in the market with state-of-the-art hydraulics and a frame that is robust.

On the list of key attributes of this FFI Hydraulic Welding Electrode Production Line is its ease of uses. The controls are intuitive, rendering it easier for anyone to leap in and initiate producing. The machine can additionally be effortlessly adjusted to fit various sizes of electrodes, which means you'll makes electrodes of every size and diameter.

Another attribute through the FFI Hydraulic Welding Electrode Production Line is definitely their longevity. This gear was created to past, with top-quality components and artistry this is highly accurate it might effortlessly conduct for decades without any decrease in good quality or effectiveness. Plus, the system that is hydraulic we greater energy on the rate and stress level associated to generation procedure, working for you to change the end led to generally work for you that are personal are proper.

Among the things being many are superb the FFI Hydraulic Welding Electrode Production Line definitely could be the efficiency. Since the strategy are certain to get pressure that is hydraulic, it could probably develop electrodes at any genuine way faster rate than traditional programs that can effortlessly be mechanized. This recommends you should make much more electrodes in a smaller period, boosting your manufacturing that will be plus that is basic.

Finally, the FFI Hydraulic Welding Electrode Production Line is a good investment that is very good any ongoing business that cares about quality. The device was created to create electrodes being top-notch performance that is consistent reliability. This implies you can depend on the electrodes generated by this relative line to accomplish at a consistent level that is high giving these potential customers the typical they expect.

No. |

Equipment |

Function |

1 |

Descaling machine |

Remove the dust from the wire. |

2 |

Tip roller |

Sharpen the tip of wire. |

3 |

Butt-welding machine |

To weld the wire tips when 1 roll is finished. |

4 |

Wire drawing machine |

To draw the wire into diameter needed. |

5 |

Single arm crane |

To lift the wires. |

6 |

Wire cutting machine |

To cut wire into size. |

7 |

Mixing Machines Double "S" Type |

Mix the powder for coating. |

8 |

Silicate Mixer |

Silicate stirring barrel is special for stirring liquid silicate. |

8 |

Wire-feed machine |

Wire supply. |

9 |

Hydraulic powder coating machine |

Coat the mixed powder onto the wire. |

10 |

Head-Tail Grinder machine |

To grind the head and tail into standard shape. |

11 |

Electrode eccentric measuring Instrument |

Eccentric checking. |

12 |

Control panel for spiral line |

Main control of electricity. |

13 |

Auxiliary line machine |

Internal conveying. |

14 |

Box type hot air circulation drying furnace(electricity) |

Drying the coating on the core. |

15 |

Words printer |

Printing dates or brand name. |

16 |

Shrink packaging machine |

Plastic packing. |

17 |

Strapping machine |

Wrapping. |

18 |

Reclaiming machine |

Peel the coating off. |

19 |

Straightening machine |

Straighten the wire. |

20 |

Vibrating screen |

To filter the recycled coating. |

EN

EN