Whatsapp: +8615215859435

Wechat:+8615215859435

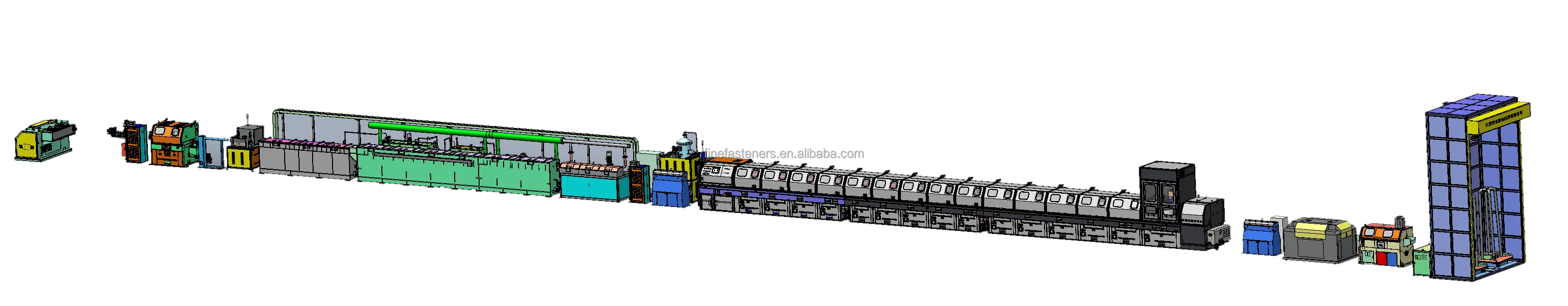

Product Name |

CO2 GAS MIG WELDING WIRE PRODUCTION LINE |

Wire Diameter |

6.5mm,5.5mm |

Brand Name |

FFI |

Year |

2022 |

Model Number |

FFI--XXCO2-6508B |

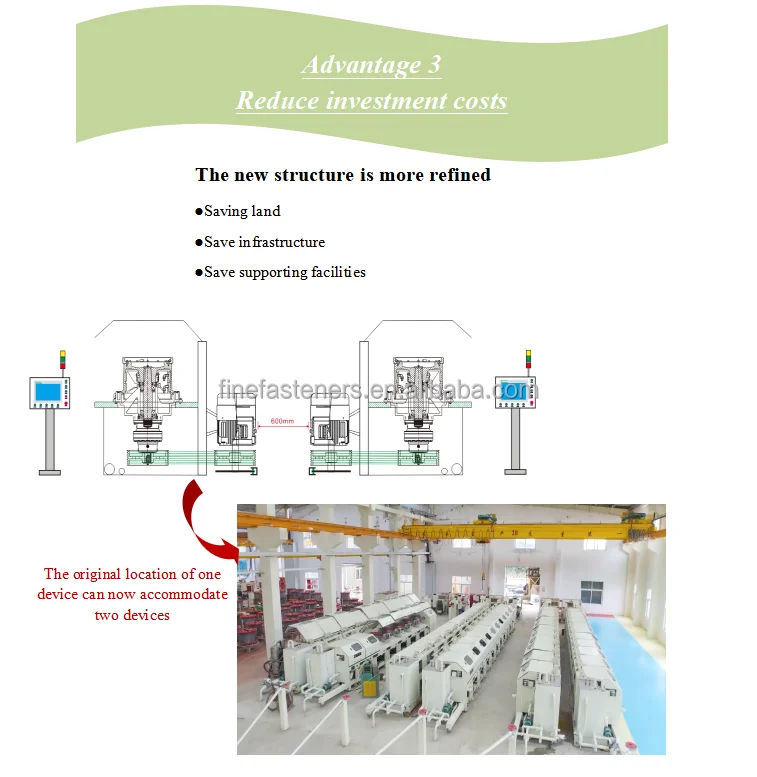

Dimension(L*W*H) |

21.5*1.450*1.6m |

Weight |

31280KG |

Place of Origin |

China |

Anhui |

|

Automatic Grade |

Semi-automatic |

Voltage |

380V or Customize |

Power |

3000W |

Machinery Capacity |

Production capacity: 0.8mm--6.5t /1.0mm-10t/1.2mm-17t (20 working hours Max one day) |

Key Machines |

Metal Electroplating Machinery, Metal Polishing Machine, Metal Sheet Processing Machine, Lathe |

Product Type |

ER70S-6 Welding wire |

Finished Product |

15kg pallet weldingwire |

Usage |

Vehicles Bridge-engineering Machine-engineering Steel structures Ship manufacture Trade container |

Type |

Gas Shield Welding Wire |

After Warranty Service |

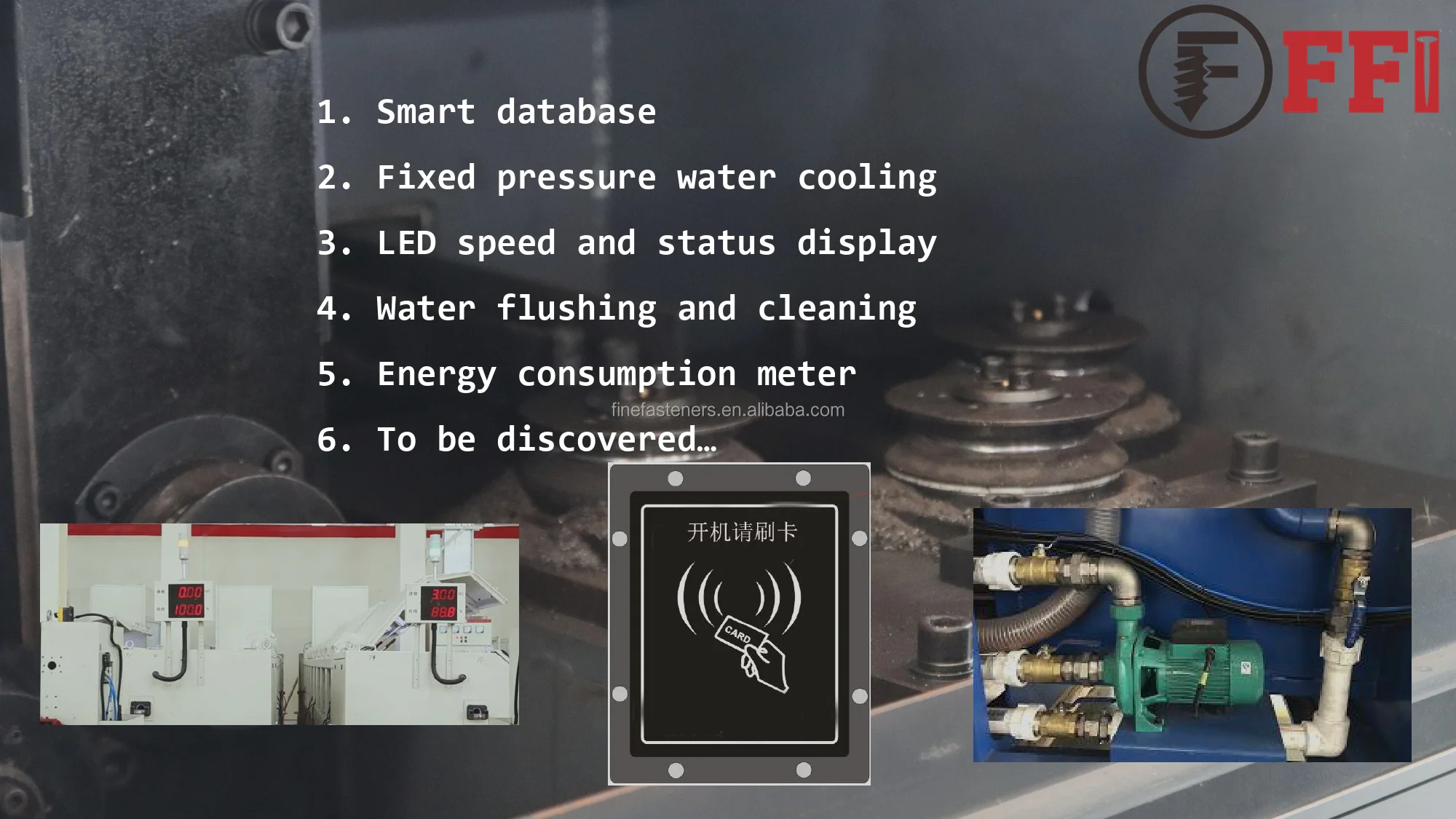

Online support, Field installation, commissioning and training |

Raw material |

Carbon Steel |

Capacity |

0.8mm--6.5t /1.0mm-10t/1.2mm-17t |

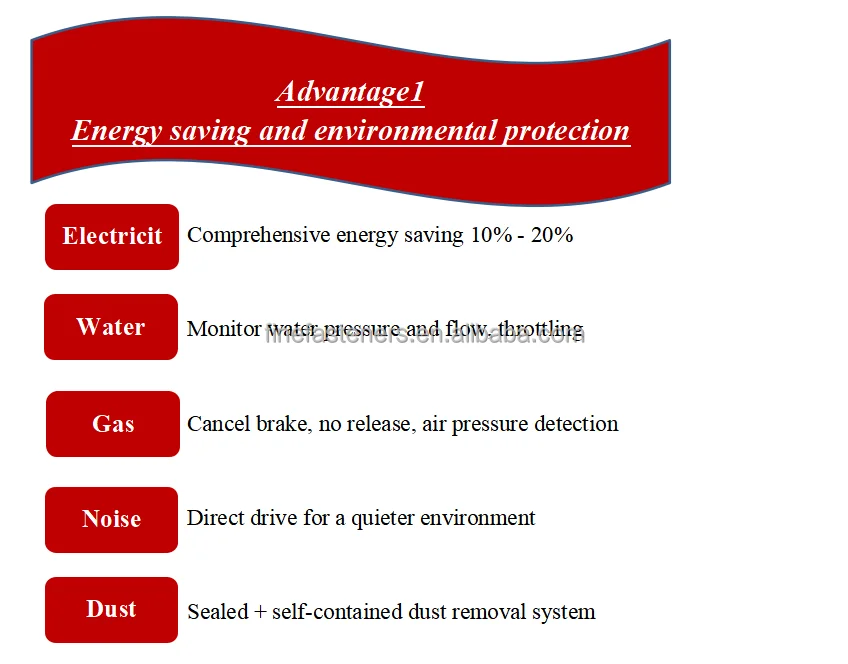

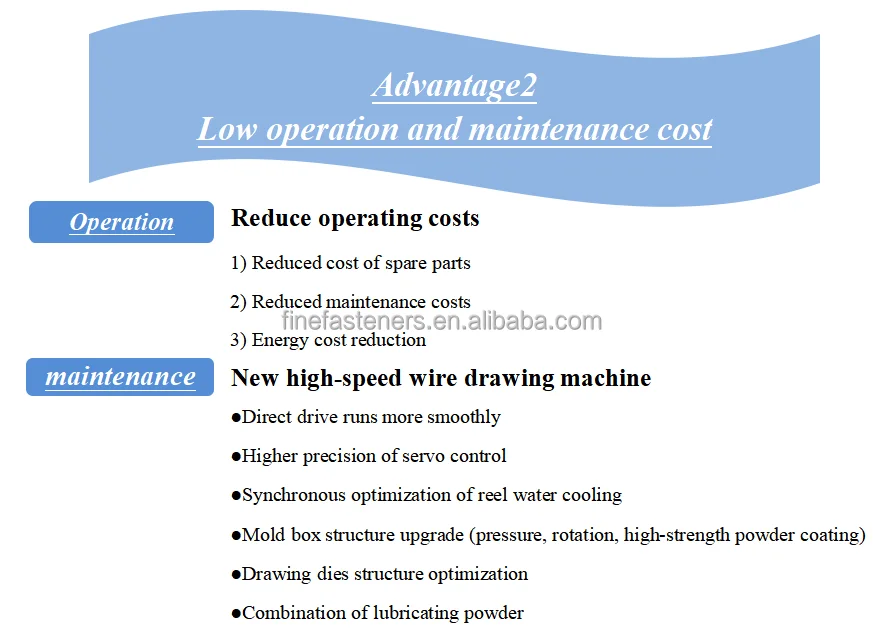

Feature |

Excellent Welding Performance |

Advantage |

Professional Manufacturer |

Certification |

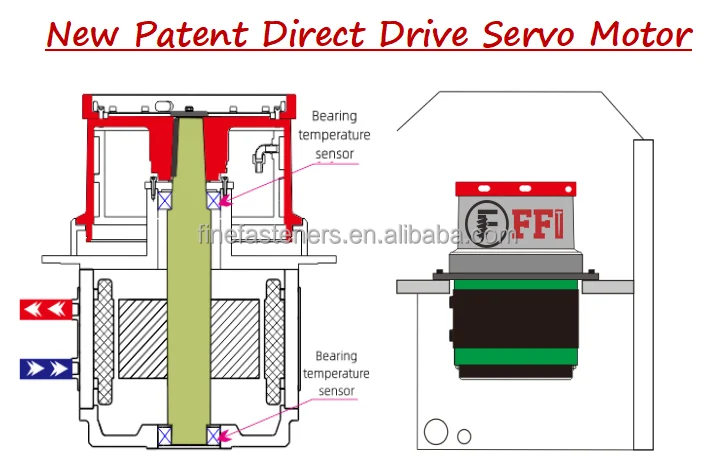

SGS CE PATENT |

Color |

Customized Color |