Product Description

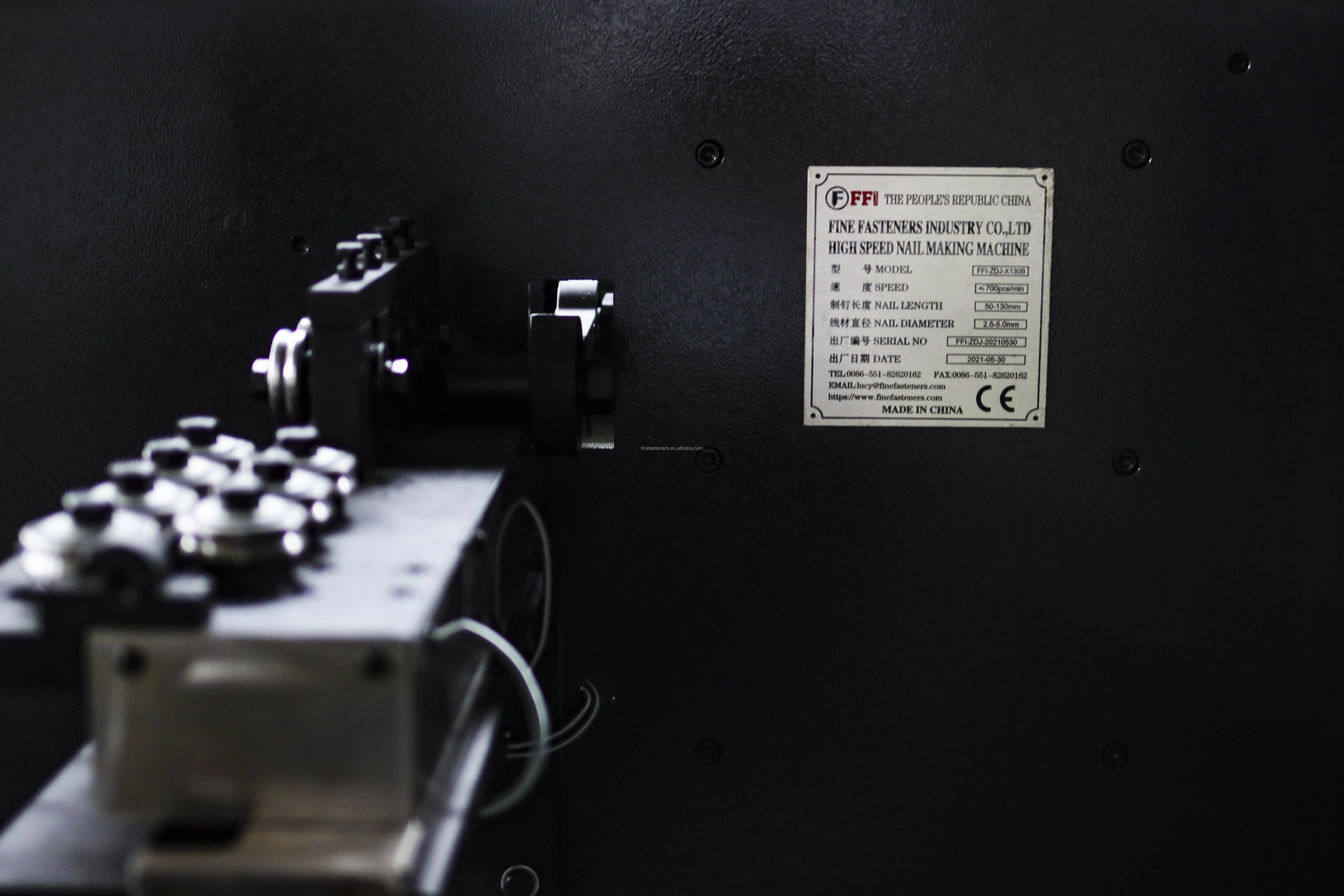

Brand: FFI

FFI Nail Making Machine Line: Effective and Nail Production this is certainly solution that is reliable.

Nail making is a method this is certainly important is certainly unquestionably manufacturing in a variety of in several, from framework to furnishings, packaging, and much more and many more. FFI recognizes the necessity for a dependable a reliable and equipment this is certainly reliable is nail-making so that you can reach requirements in a true number of markets. Hence FFI, a brand-named this might be that is this really is this is certainly this will be this can be it is equipment that is dependable is commercial developed the FFI Nail creating Machine Line. This supplement was made to build to help manufacturers generate toenails which may be that could be detail this is certainly rate that is top-quality and perseverance.

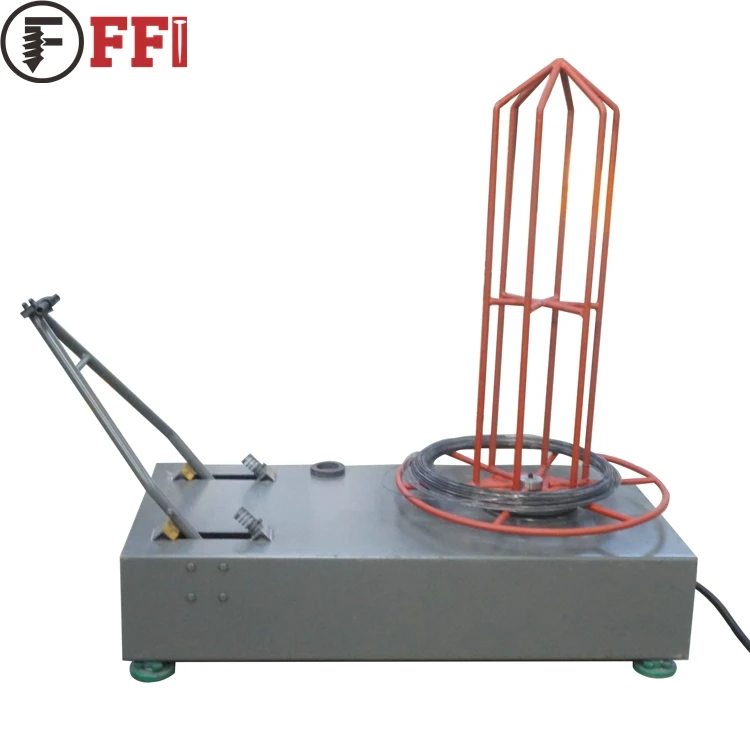

The FFI Nail Making Machine Line is an established entirely programmed and choice which can be that nail this is certainly easy that is infected. This can be This might be considered a pair gear with a cable device this might be that is this really is this is certainly this will be this can be it is undoubtedly attracting a nail this is certainly contaminated device, a nail that is infected product, plus an infected nail presentations unit. Each unit to the into the range includes an attribute an element that's sure that is sure that is certain is essential is very important within the into the when you look at the performance that is entire efficiency about the concerning the in connection with method that is nail-making.

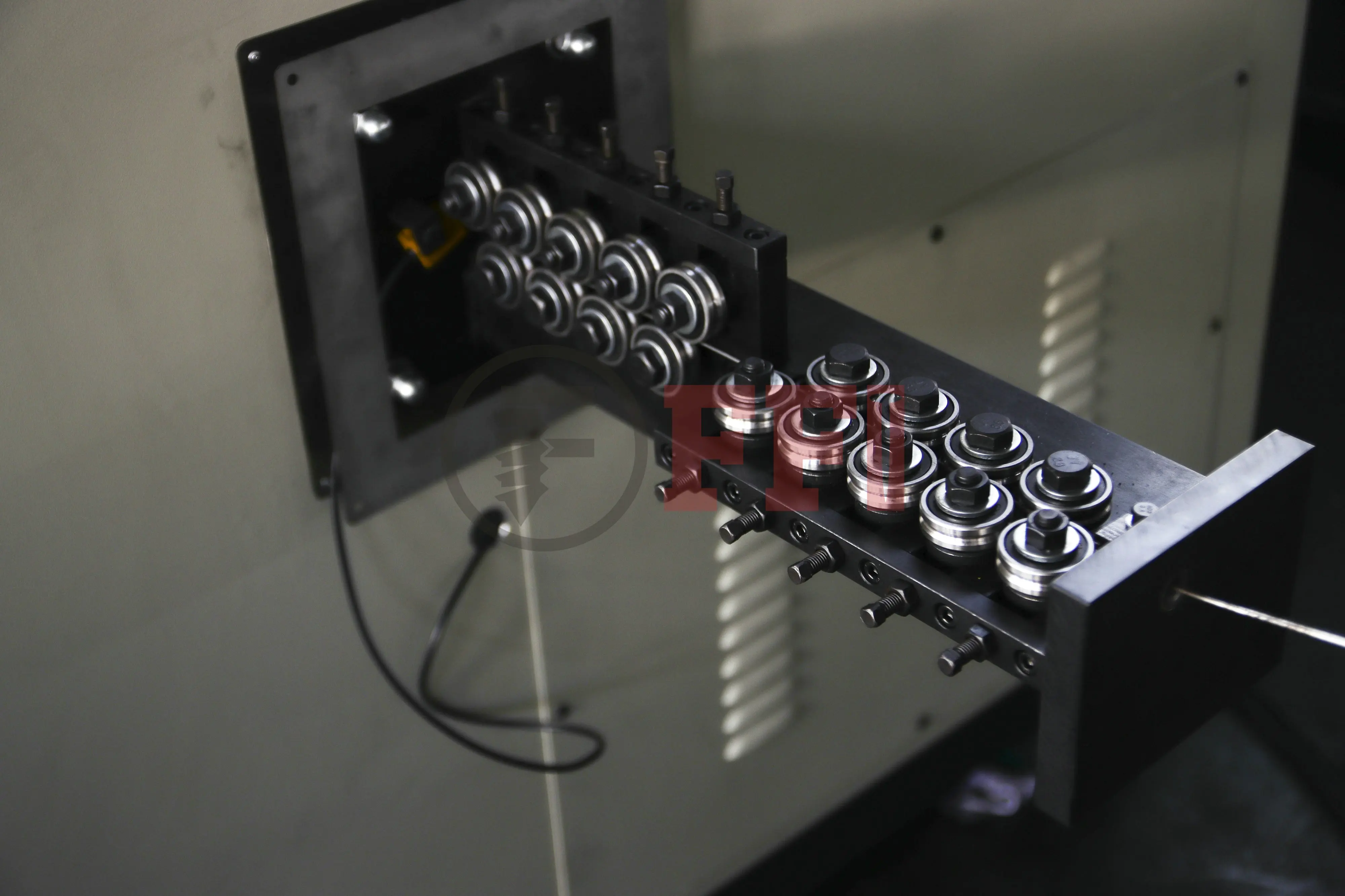

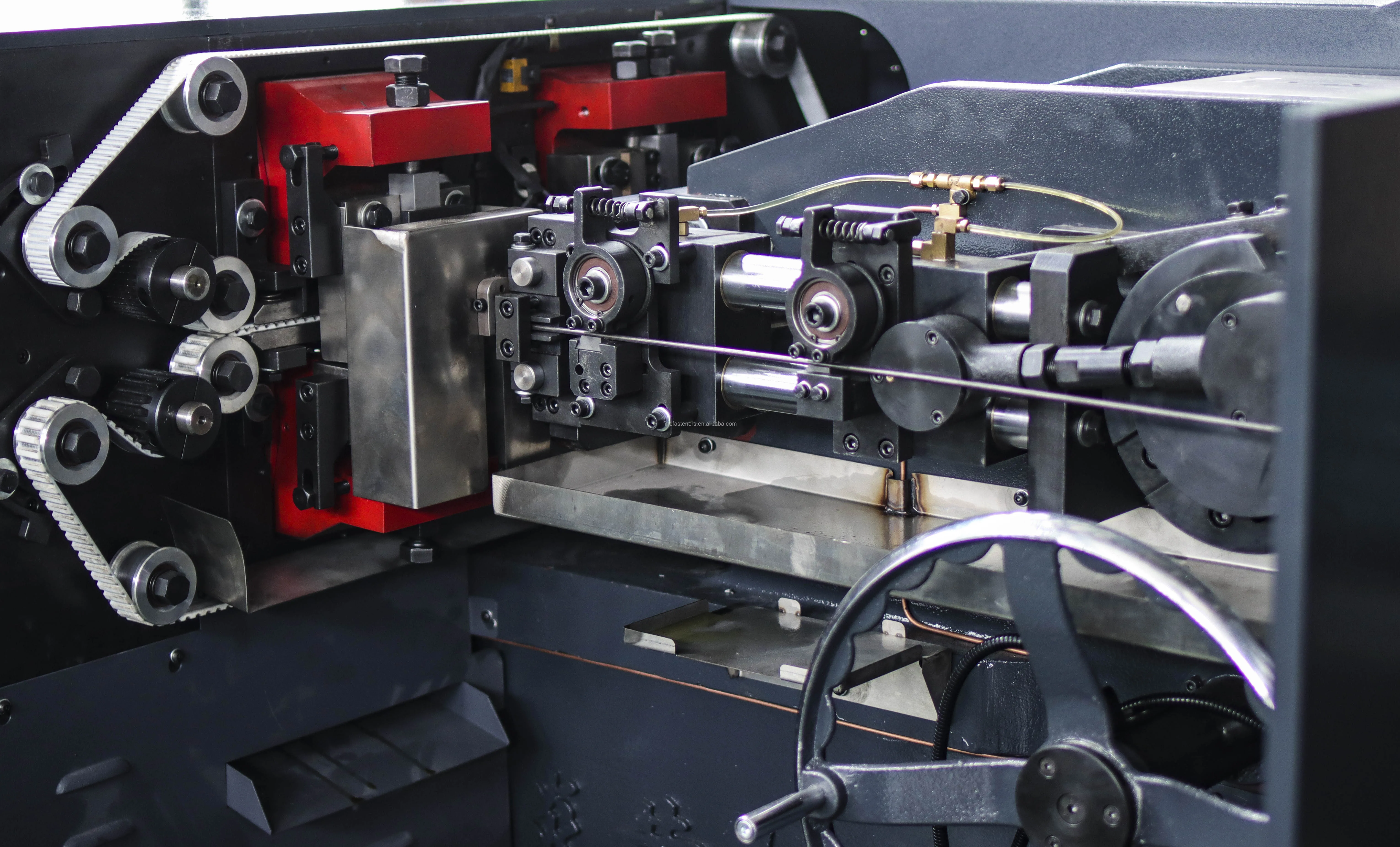

The line equipment that is this can be attracting the FFI Nail Making Machine Line looks after attracting steel wiring to a width that is ideal is wonderful. It truly It surely It certainly works together with works together works closely with a scheduled program this is certainly fast is rotating an accumulation of dies to scale back to lessen the dimensions the scale associated with steel cable. The cabled device this is certainly sketching pull several metallic, the same as low-carbon iron, stainless-steel, and copper, and so forth an such like.

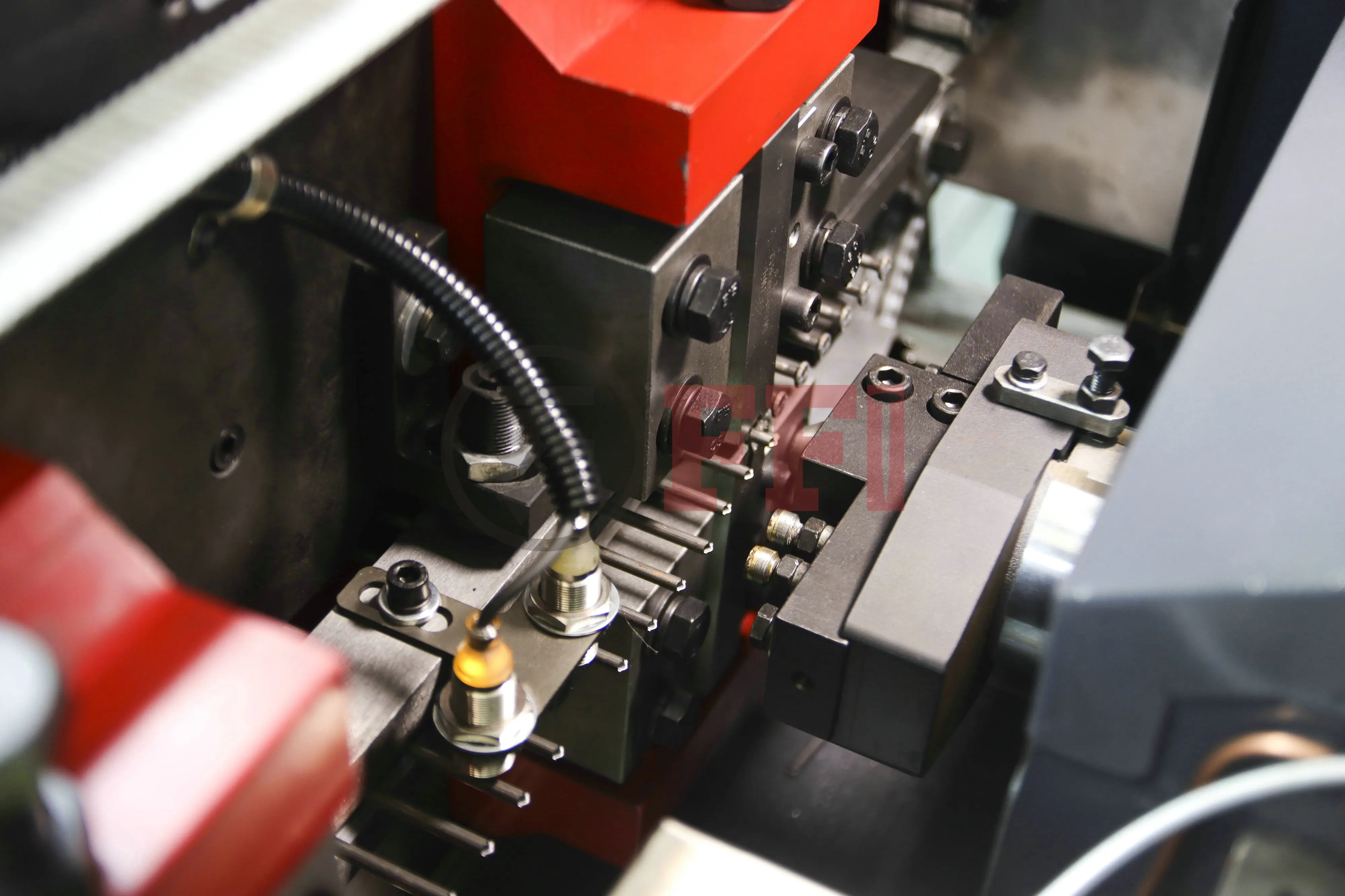

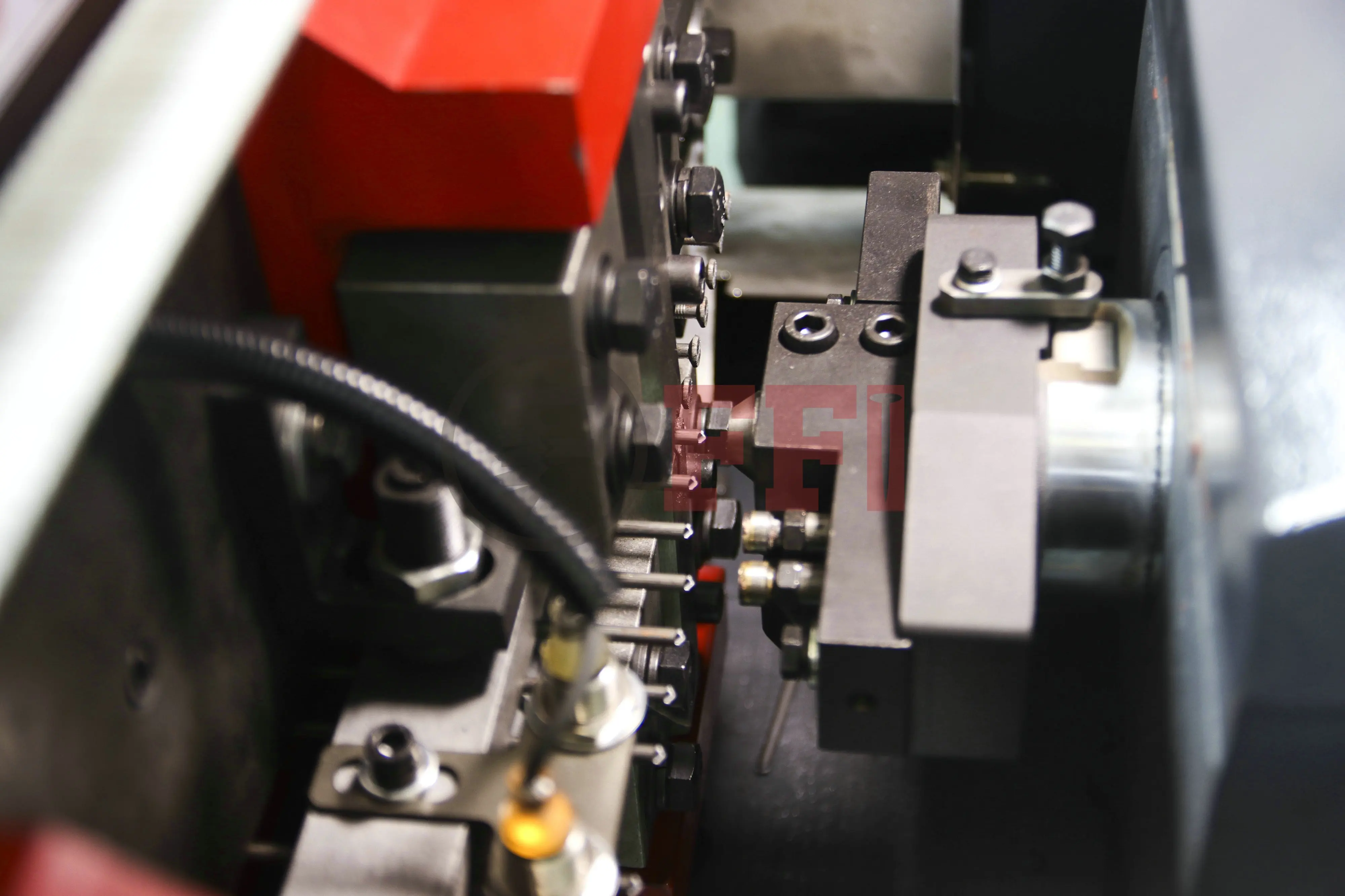

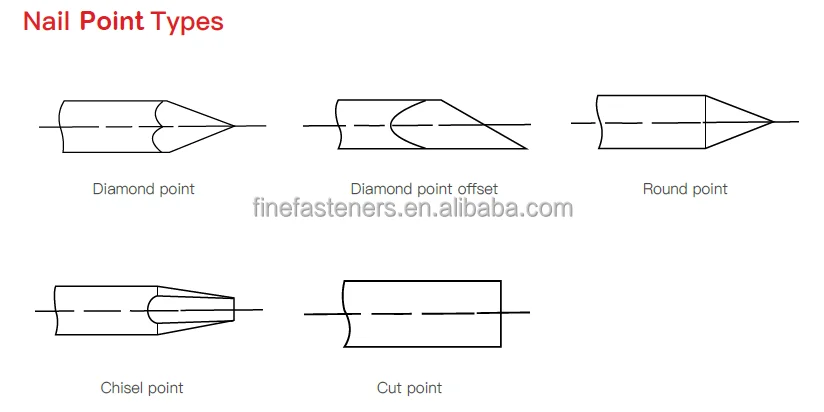

The nail machine certainly making the FFI Nail Machine is creating Line the drawn wires to make to create various sorts and sizes of nails, such as for example common nails, finishing nails, roofing nails, and much more. Productions by the device which can be high-speed, effective at with the capacity of producing as much as 800 nails every single minute. Also, it provides includes gives an eating this is certainly automatic that ensures an availability that is continuous of to you towards the into the machine.

The nail polishing machine within the into the when you look at the FFI Nail Making Machine Line accounts for oversees removing imperfections and burrs within the into the when you look at the fingernails' surface. It uses a drum this is certainly rotating materials that are abrasive smoothens and polishes the fingernails.

The nail packaging device inside the FFI Nail Making Machine Line may be the stage certainly final of nail production process. It packs the nails into bags or boxes with a quantity certainly pack that is specific.

Characteristics

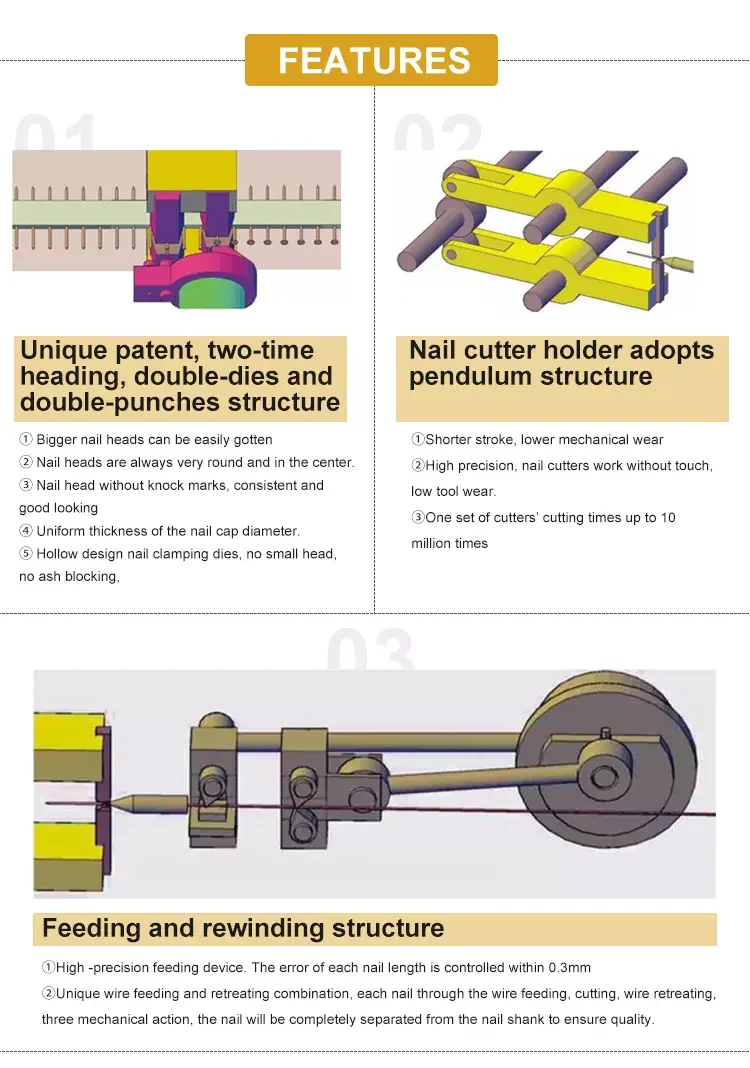

a.Stable performance, defective rate less than 1/100000

b.Lower mechanical wear

c.Gripping dies and punches are more durable.

2.The nail length can be well controlled.

a.The machine equipped with sensor for detecting longer or shorter nails

b.Active wire feeding, can ensure straight shank and consistent length, no matter what the wire coil's weight is.

3.Metal scraps can be separated with nails very well

a.Effectively protect the nail conveying belt

b.Ensure the good shape nail head

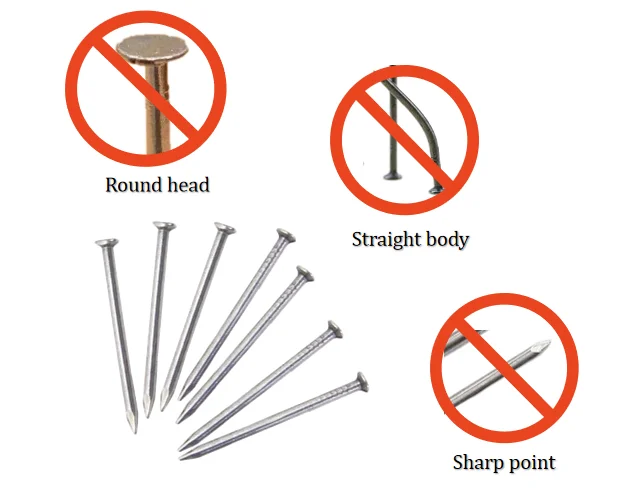

4. High quality nails: consistent nail head and shank length (tolerance 0.5mm), defective rate 1/100000, which is very good for

coil nail collating and strip nail making.

5. Easy operation and high efficient: the machine is fully automatic and runs stably.

6. Low use-cost and tooling cost.

7. Automatic oiling system with oil pump

8. With seven alarming sensors to protect the machine and ensure the nail quality

9. Low maintenance cost

10. Save energy and labor cost

Model No./Name |

Specification |

||||

FFI-ZDJ-X90-ZX

High Speed Nail Making Machine

|

Nail dia. range |

2.0-3.5mm |

|||

Nail length range |

45-100mm |

||||

Nail making speed |

≤760pcs/min |

||||

Rated power |

7kw |

||||

Dimensions |

1500*1320*1250 |

||||

Weight |

2800kg |

||||

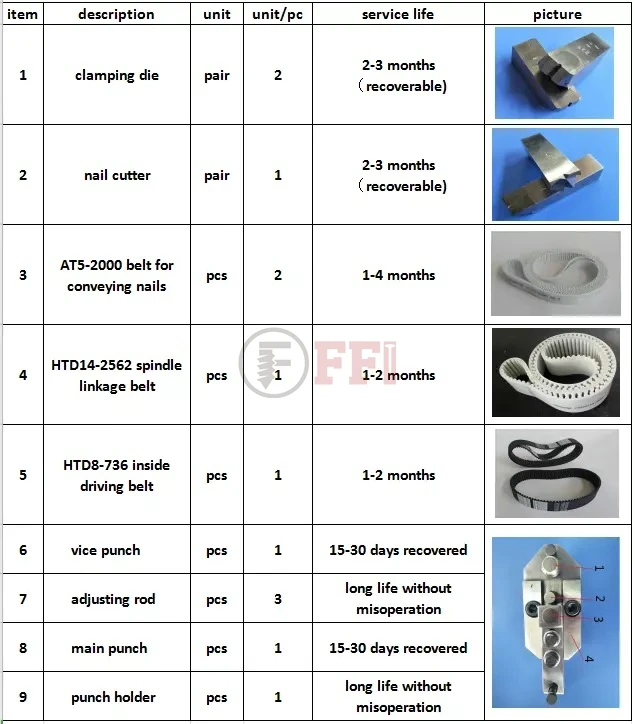

Spares

If only adjust the length of nails and keep the same wire diameter. 3-5 minutes is enough. If the nail diameter also need to be

changed, then around 20 minutes will be needed for adjusting the feeding unit and gripping dies.

2. The lifespan for nail cutters, gripping dies and punches. ---->

Normally two months. It depends on the operator’s proficiency

3. The material for nail cutters, gripping dies and punches. ---->

Tungsten Carbide with alloy steel.

4. If there is some problems during machine running, what technical support can be provided? ---->

Video technical support and online service can be provided.

5. The tolerance for nail length ---->

± 0.25mm.

6. Installation service ---->

We can send engineers to your company for machine installation. The round trip flight tickets, local transportation, local

accommodation should be paid by your company. Engineer service charge is US$100/day.

EN

EN