Product Description

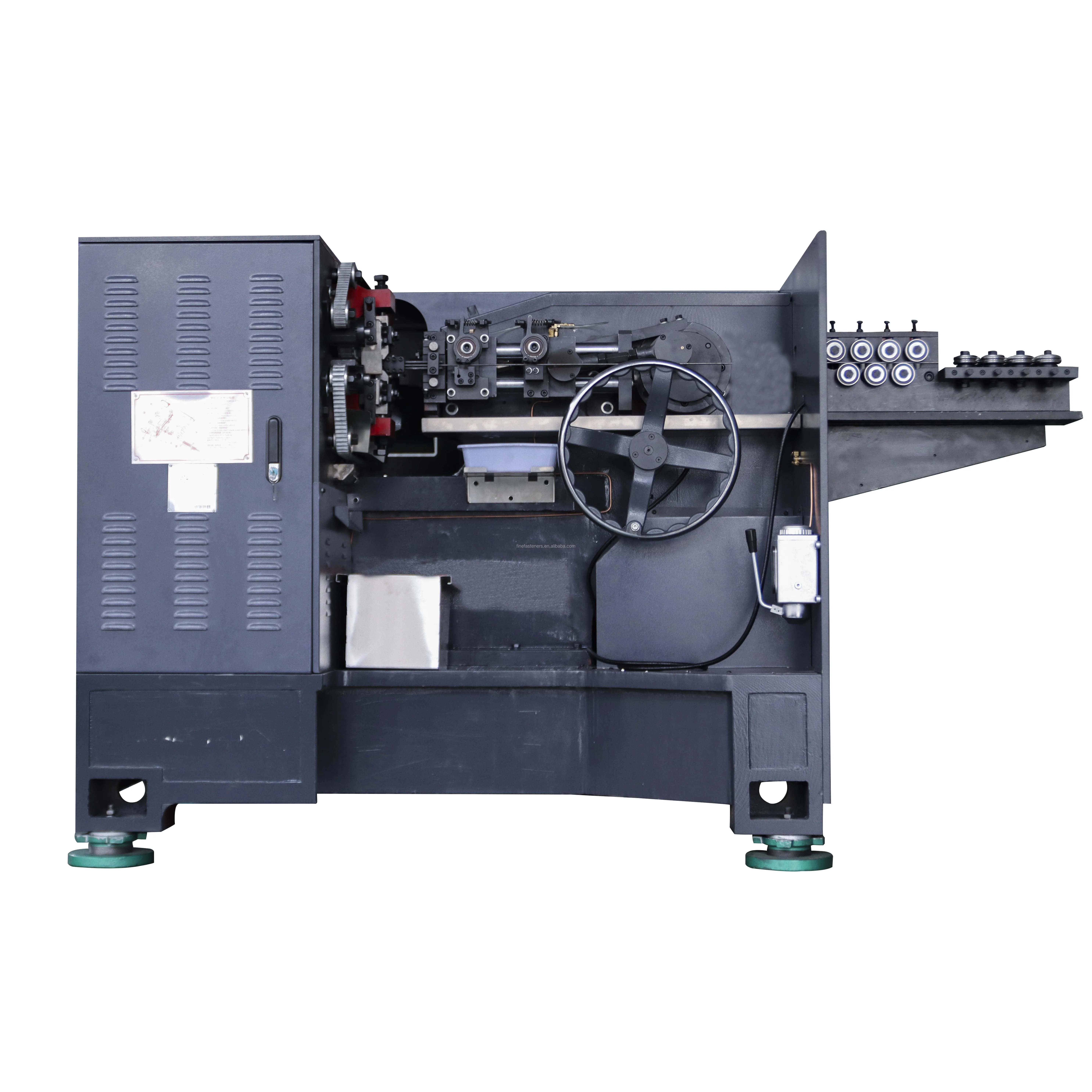

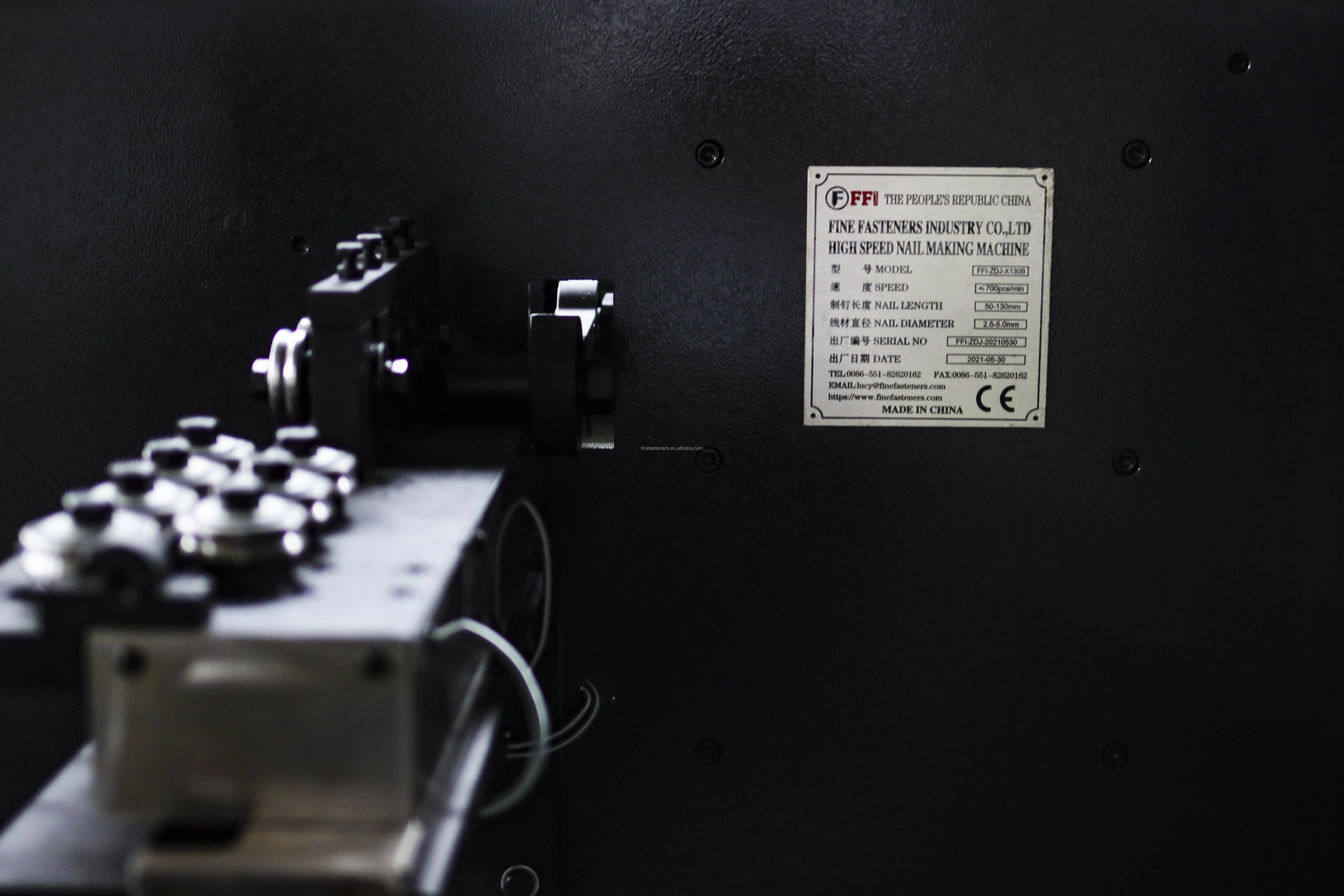

The FFI tall Speed Nail machine this is certainly making the solution that is best for high volume nail production. This machine is beneficial at creating up to 800 nails each and every minute, making this the perfect tool for large-scale manufacturing companies which consists of state-of-the-art technology.

This nail device that is making built to be easy to use, dependable, and efficient. It is perfect for producing different sizes of fingernails, along with are produced by it at high speeds without compromising quality. Its made from top-quality materials that guarantee durability and longevity, making sure you are getting the worthiness that is way better for the investment.

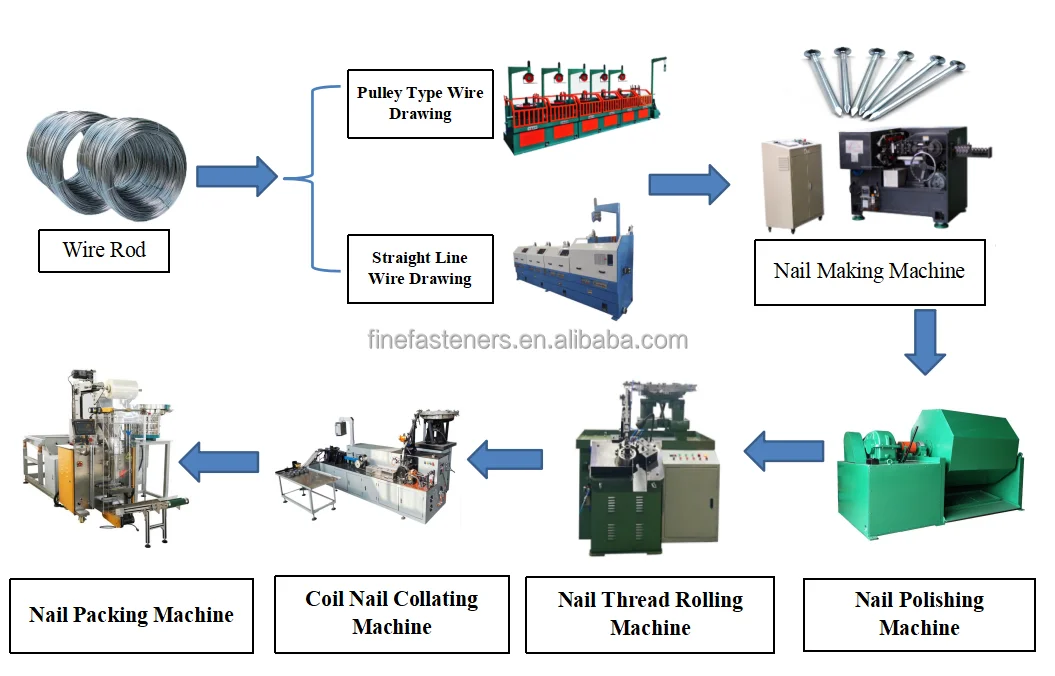

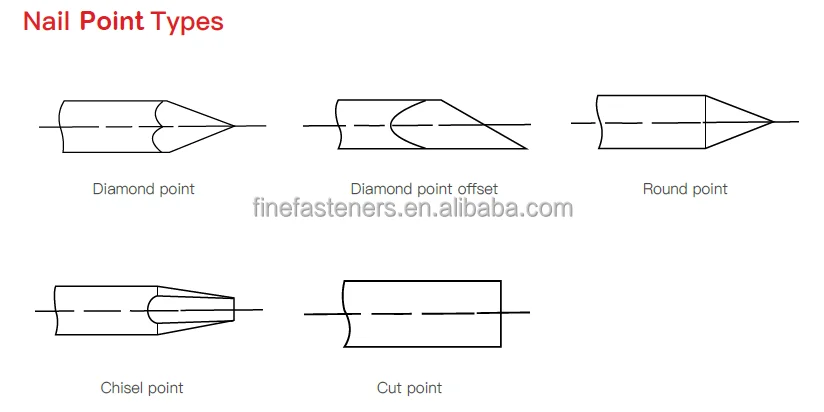

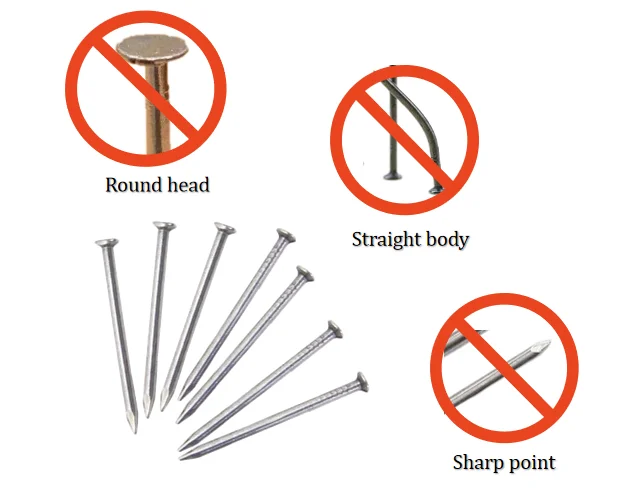

Certainly one of its standout features is being able to create various kinds of nails with ease. This revolutionary product can create wire this is certainly circular, flat mind fingernails, and concrete nails, yet others. It is versatile, and you will customize it to meet up your requirements that are specific which makes it a asset that is valuable have in your manufacturer.

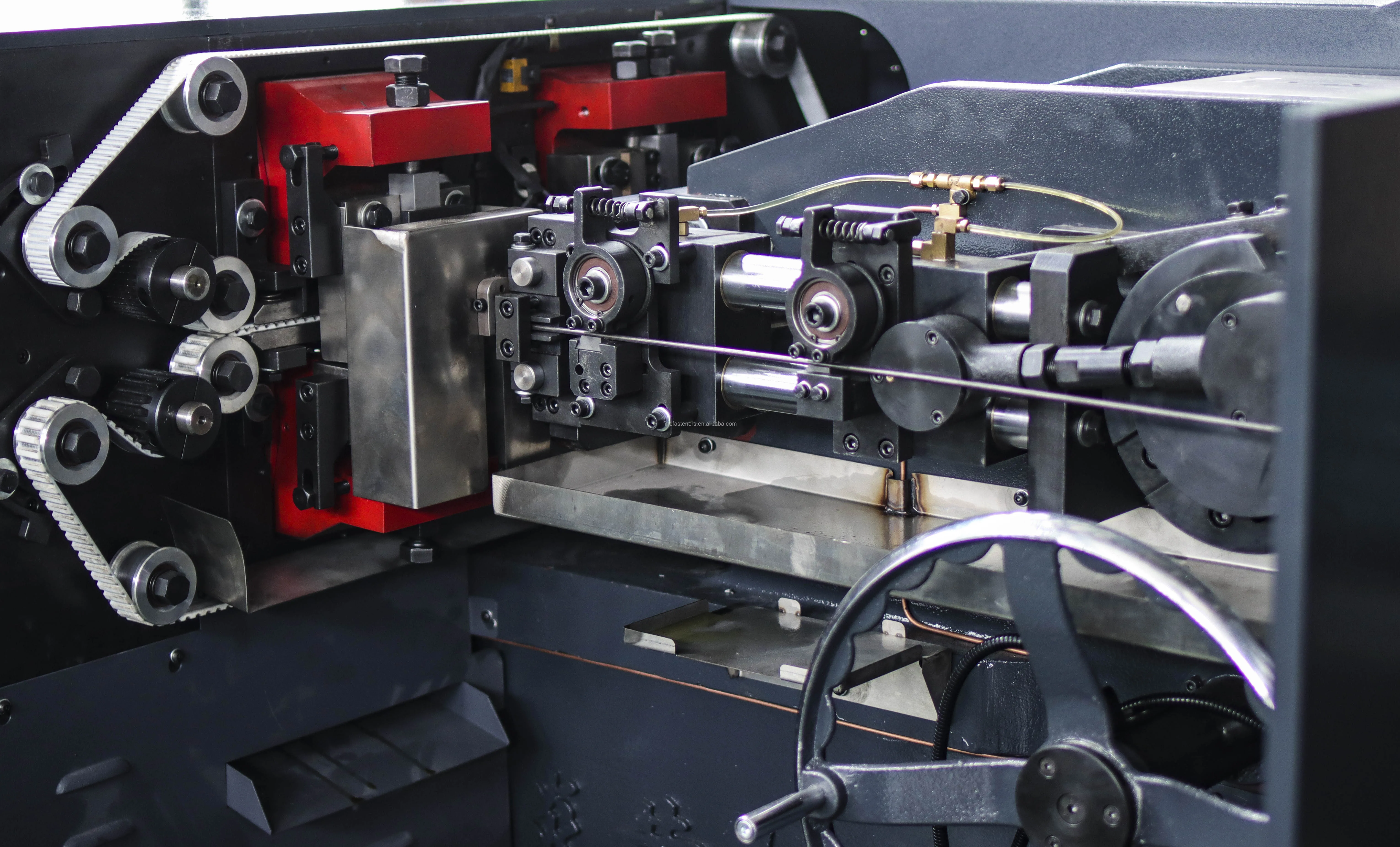

The FFI High Speed Nail Making Machine includes a simple design which allows for effortless upkeep, reducing downtime and productivity that is increasing. Its technology that is advanced guarantees it operates quietly and smoothly, minimizing the possibility of accidents and injuries to your workers.

This nail machine that is making also energy-efficient, reducing your costs that are functional. Its built to eat energy that is minimal achieving optimum production, making certain you're going to get the finest of both worlds.

The FFI High Speed Nail Making Machine saves space in your manufacturing plant along side its compact size. You can easily install and run, making certain you can quickly get going doing all your nail production operations. Additionally it is safe to use, in addition to its features being user-friendly it simple for the workers to utilize without compromising their safety.

Characteristics

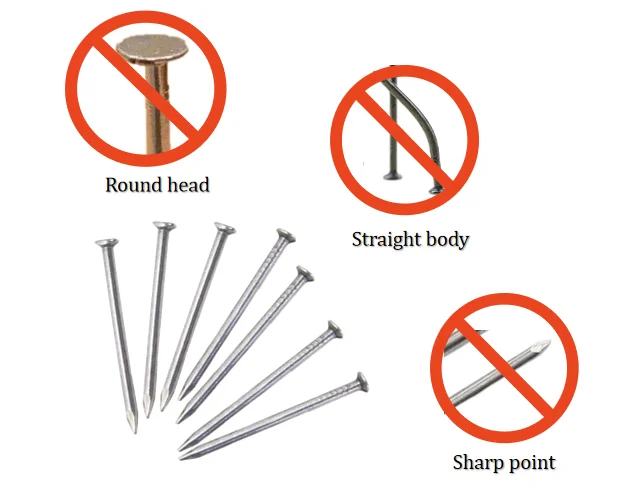

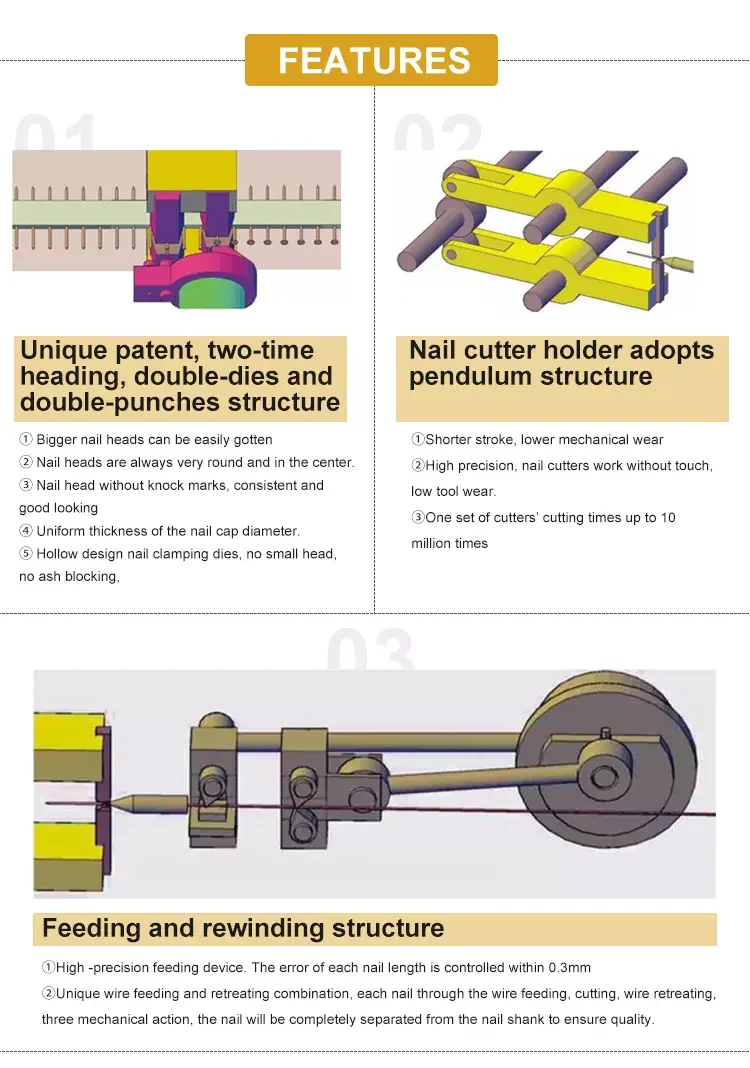

a.Stable performance, defective rate less than 1/100000

b.Lower mechanical wear

c.Gripping dies and punches are more durable.

2.The nail length can be well controlled.

a.The machine equipped with sensor for detecting longer or shorter nails

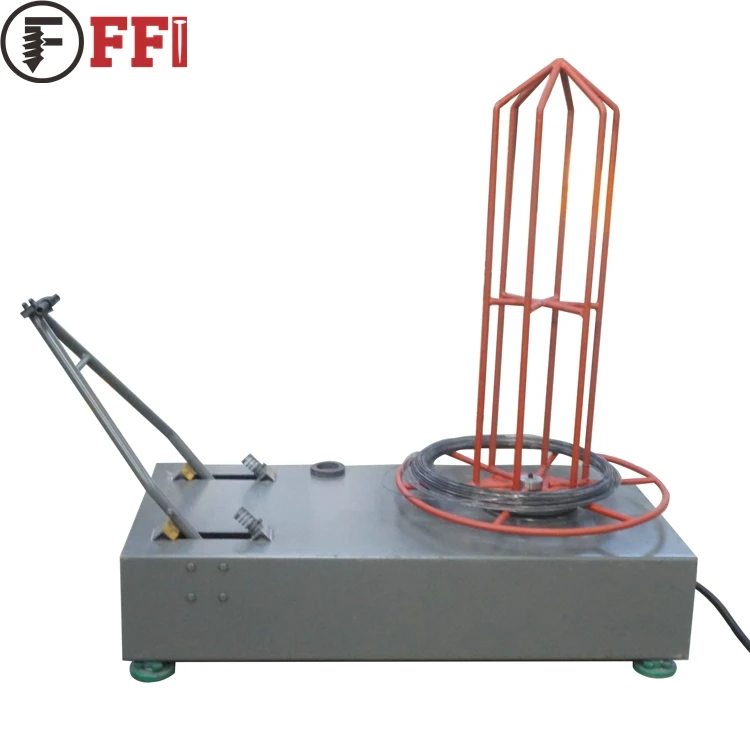

b.Active wire feeding, can ensure straight shank and consistent length, no matter what the wire coil's weight is.

3.Metal scraps can be separated with nails very well

a.Effectively protect the nail conveying belt

b.Ensure the good shape nail head

4. High quality nails: consistent nail head and shank length (tolerance 0.5mm), defective rate 1/100000, which is very good for

coil nail collating and strip nail making.

5. Easy operation and high efficient: the machine is fully automatic and runs stably.

6. Low use-cost and tooling cost.

7. Automatic oiling system with oil pump

8. With seven alarming sensors to protect the machine and ensure the nail quality

9. Low maintenance cost

10. Save energy and labor cost

Model No./Name |

Specification |

||||

FFI-ZDJ-X90-ZX

High Speed Nail Making Machine

|

Nail dia. range |

2.0-3.5mm |

|||

Nail length range |

45-100mm |

||||

Nail making speed |

≤760pcs/min |

||||

Rated power |

7kw |

||||

Dimensions |

1500*1320*1250 |

||||

Weight |

2800kg |

||||

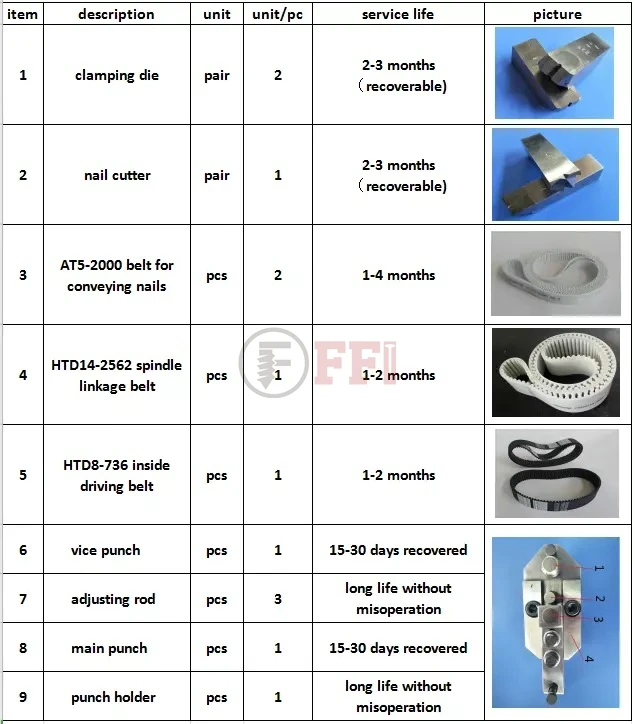

Spares

If only adjust the length of nails and keep the same wire diameter. 3-5 minutes is enough. If the nail diameter also need to be

changed, then around 20 minutes will be needed for adjusting the feeding unit and gripping dies.

2. The lifespan for nail cutters, gripping dies and punches. ---->

Normally two months. It depends on the operator’s proficiency

3. The material for nail cutters, gripping dies and punches. ---->

Tungsten Carbide with alloy steel.

4. If there is some problems during machine running, what technical support can be provided? ---->

Video technical support and online service can be provided.

5. The tolerance for nail length ---->

± 0.25mm.

6. Installation service ---->

We can send engineers to your company for machine installation. The round trip flight tickets, local transportation, local

accommodation should be paid by your company. Engineer service charge is US$100/day.

EN

EN