Product Description

The FFI X90 Founder Nail device this is certainly building a versatile and device that is efficient anyone in need of top-notch nails for assorted projects. An amateur DIY enthusiast, or a large-scale manufacturer, this product will help produce nails at an immediate pace with unmatched accuracy whether you are a carpenter that is professional.

The FFI X90 Founder Nail device this is certainly building a versatile and device that is efficient anyone in need of top-notch nails for assorted projects. An amateur DIY enthusiast, or a large-scale manufacturer, this product will help produce nails at an immediate pace with unmatched accuracy whether you are a carpenter that is professional.

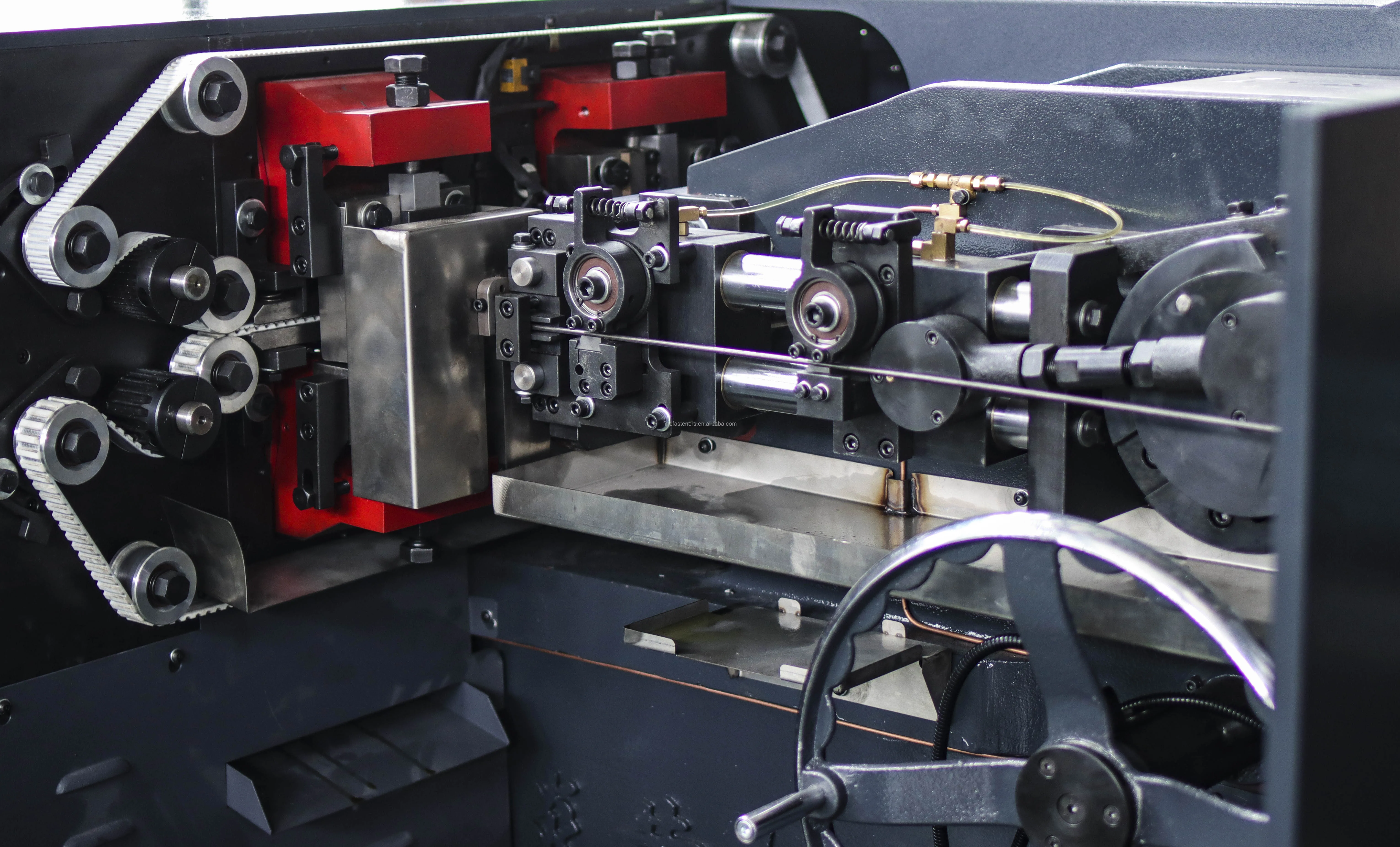

Utilising the FFI X90 Founder Nail device that is making extremely user-friendly. A control is had by the device that is easy that allows you to definitely adjust the nail size, quantity, and speed. It is possible to effectively switch between various nail sizes and types to ensure that you can tackle any task that comes the right path.

The FFI X90 Founder Nail device that is making developed to make manufacturing faster and much more efficient. It might create just as much as 700 nails each minute, and that means you will make a number that is significant of in a quick timeframe. Additionally, the apparatus is sold with multiple feed rollers which will last to fifty cables, enabling you to create different types of fingernails simultaneously.

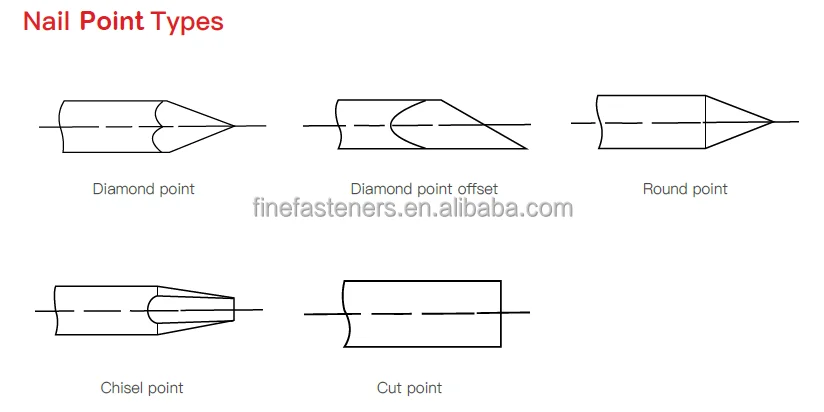

The machine is not only quick but additionally accurate. The FFI X90 Founder Nail device that is making create fingernails insurance firms a diameter starting from 1.2mm to 4mm and lengths from 9mm to 200mm. These devices's precision helps to ensure that the fingernails produced are consistent in proportions, shape, and quality.

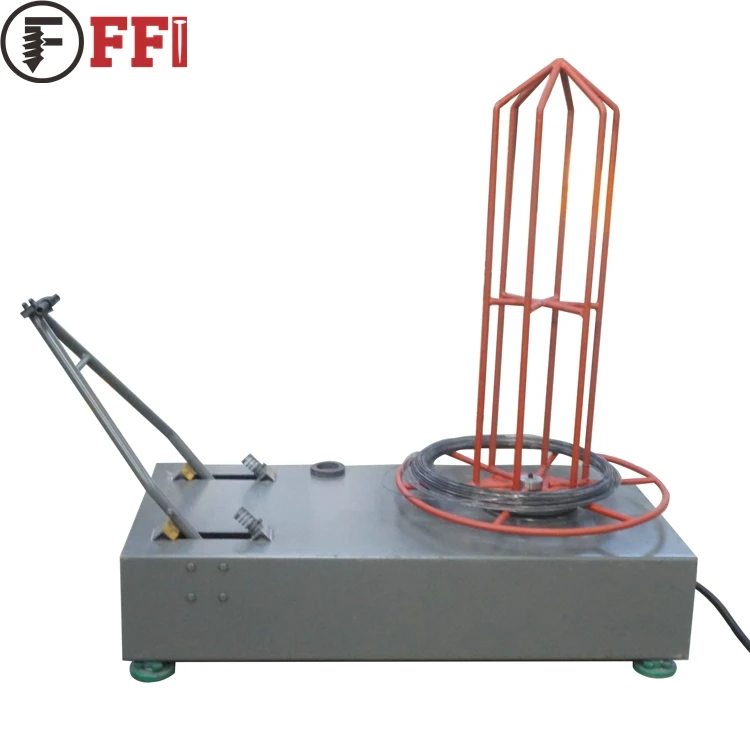

Additionally, the FFI X90 Founder Nail machine this is certainly making made with safety at heart. The device's safety guard protects the operator from the components that are going stops any accidents and that can be potential. The electrical and components that are mechanical been developed to be simple to get at for upkeep.

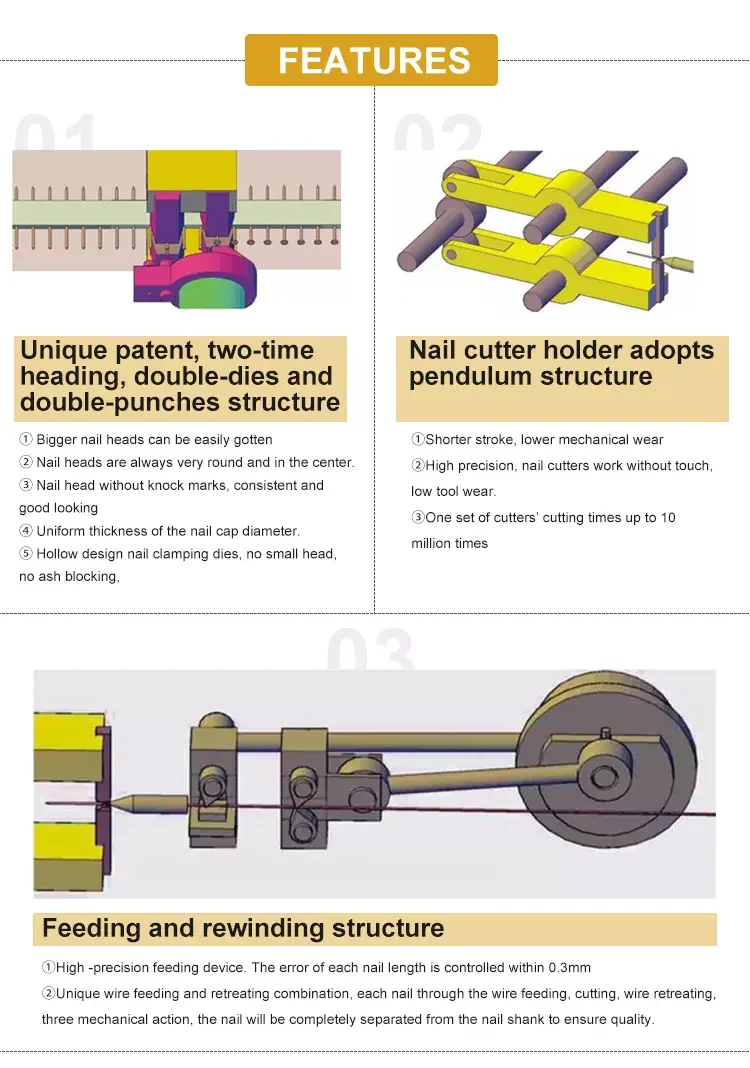

Characteristics

a.Stable performance, defective rate less than 1/100000

b.Lower mechanical wear

c.Gripping dies and punches are more durable.

2.The nail length can be well controlled.

a.The machine equipped with sensor for detecting longer or shorter nails

b.Active wire feeding, can ensure straight shank and consistent length, no matter what the wire coil's weight is.

3.Metal scraps can be separated with nails very well

a.Effectively protect the nail conveying belt

b.Ensure the good shape nail head

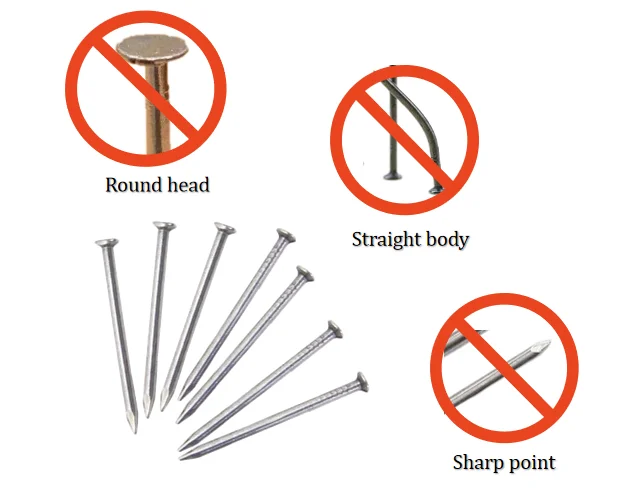

4. High quality nails: consistent nail head and shank length (tolerance 0.5mm), defective rate 1/100000, which is very good for

coil nail collating and strip nail making.

5. Easy operation and high efficient: the machine is fully automatic and runs stably.

6. Low use-cost and tooling cost.

7. Automatic oiling system with oil pump

8. With seven alarming sensors to protect the machine and ensure the nail quality

9. Low maintenance cost

10. Save energy and labor cost

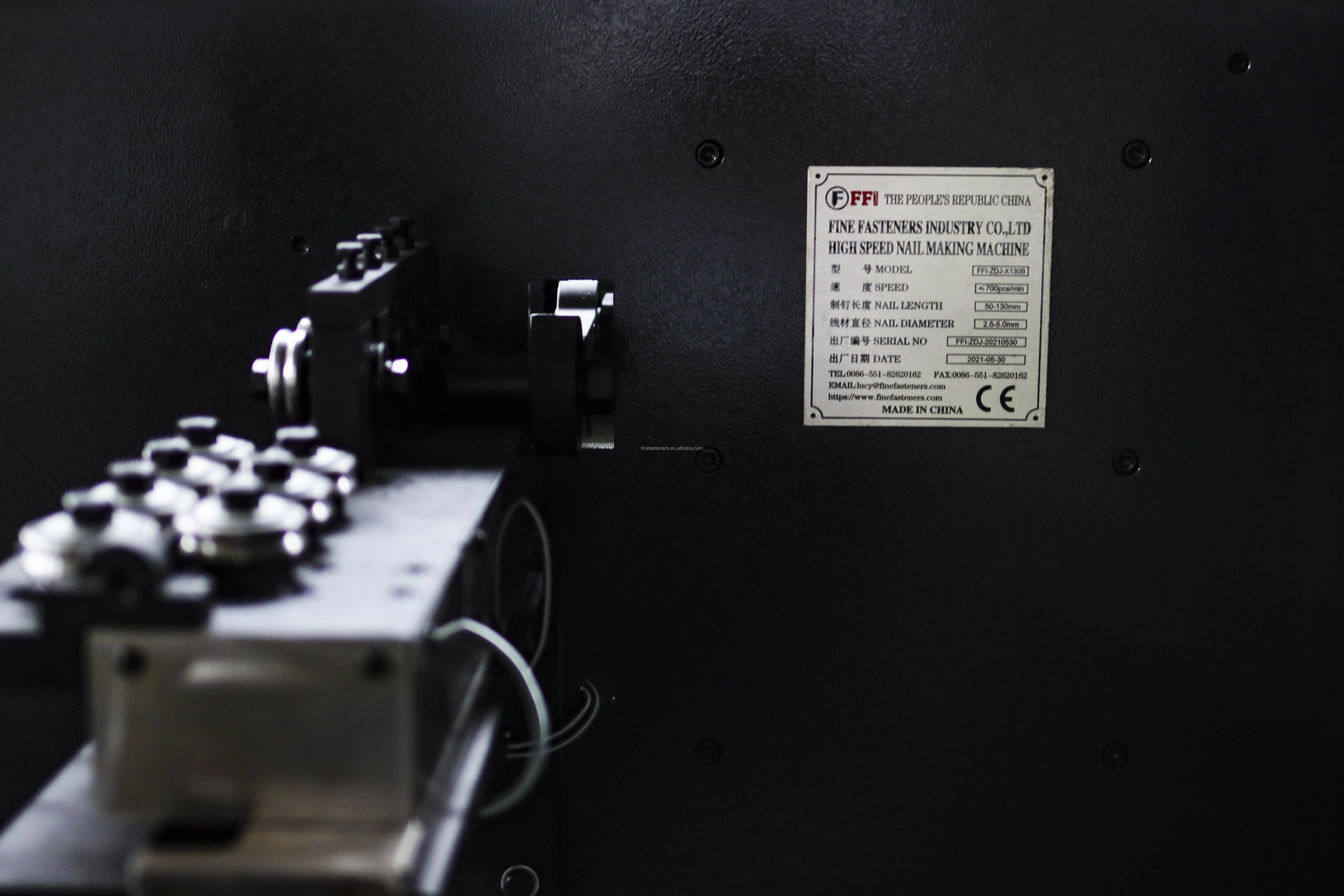

Model No./Name |

Specification |

||||

FFI-ZDJ-X90-ZX

High Speed Nail Making Machine

|

Nail dia. range |

2.0-3.5mm |

|||

Nail length range |

45-100mm |

||||

Nail making speed |

≤760pcs/min |

||||

Rated power |

7kw |

||||

Dimensions |

1500*1320*1250 |

||||

Weight |

2800kg |

||||

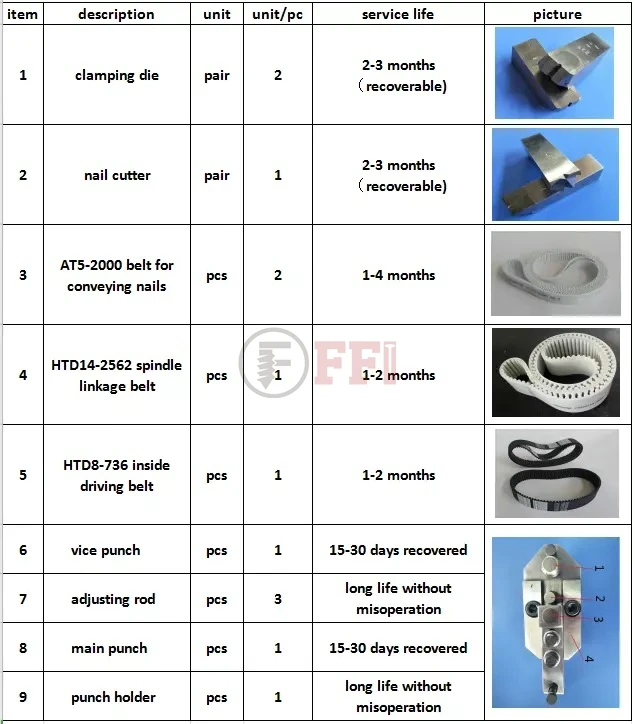

Spares

If only adjust the length of nails and keep the same wire diameter. 3-5 minutes is enough. If the nail diameter also need to be

changed, then around 20 minutes will be needed for adjusting the feeding unit and gripping dies.

2. The lifespan for nail cutters, gripping dies and punches. ---->

Normally two months. It depends on the operator’s proficiency

3. The material for nail cutters, gripping dies and punches. ---->

Tungsten Carbide with alloy steel.

4. If there is some problems during machine running, what technical support can be provided? ---->

Video technical support and online service can be provided.

5. The tolerance for nail length ---->

± 0.25mm.

6. Installation service ---->

We can send engineers to your company for machine installation. The round trip flight tickets, local transportation, local

accommodation should be paid by your company. Engineer service charge is US$100/day.

EN

EN