Product Description

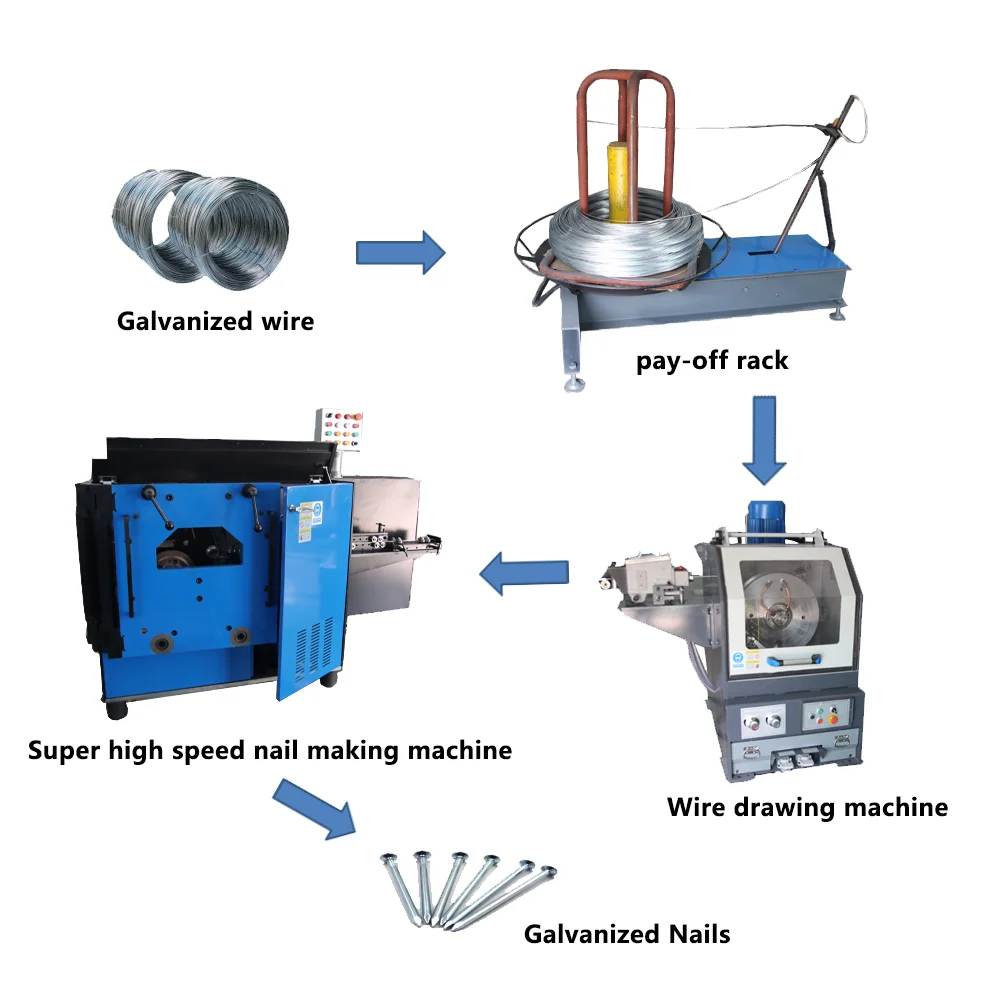

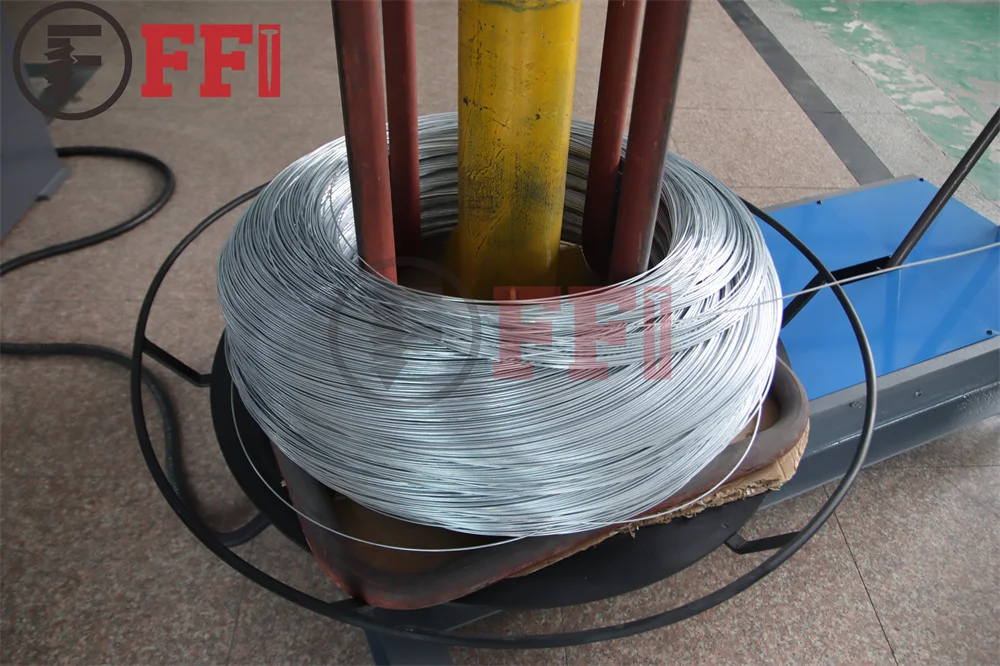

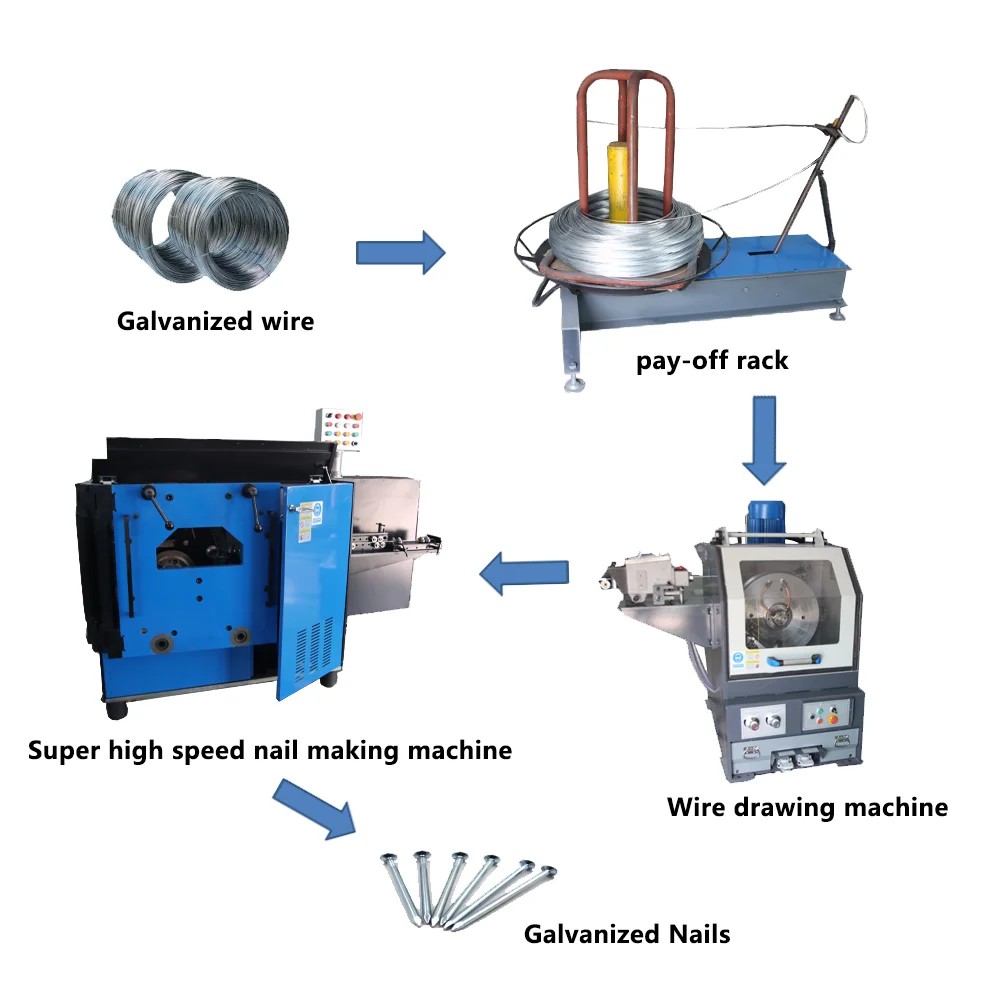

Presenting the premium Cable Toefingernail Manufacturing Line from FFI! Our advanced innovation and equipment that is also effective it feasible to build nails being premium are superb for building and construction, crafts, or DIY tasks.

With this specific advantage that is particular is cutting line, we make sure that every cable toefingernail is generated in your basic that is optimal to use - guaranteeing sturdiness in addition to reliability of the product. The technique that's entire of wire little finger fingernails may nevertheless appear hard on our manufacturing line is made ease-of-use that is utilizing your head. Just feed the cable Stright into the device, as well as in addition see because it really is become fingernails that are first-class product.

Utilizing the innovation which will be many recent, our Cable Toefingernail Manufacturing Line has a feeder that is electronic which permits the producer to quickly set up initiative because well as effectively on many factors. Our devices are maybe not tough to utilize and also demands barely any ability that's technical providing it a enhance that is fantastic variety of production organization or lover that is DIY.

With this installation line, it can be done to understand a production that is smooth procedure, which may generate a variety that is huge of dimensions to match your work demands. Ensures that each toefingernail that fallen leaves our production unit is excellent, to assist you rely on your own products and additionally maintain your consumers satisfied.

The FFI Cable Toefingernail Manufacturing Line has really also been developed to decrease lose, production it eco-friendly. Actually, our installation line is among probably one of the most effective offered to you, conserving the two of your money and time.

Our group at FFI takes satisfaction in supplying quality assurance that is on top to the customers, and that is why we give warranty on muscles quality that is better of your Cable Toefingernail Manufacturing Line. We wait until our product and likewise our quantity of experts provides extraordinary customer care along with support in previous times, throughout in addition to after grab.

Purchase currently and additionally have the best in Cable Toefingernail Manufacturing Line innovation.

Model No./Name |

Specification |

||||

FFI-SH-001

Super High Speed Nail Making Machine

|

Nail dia. range |

2.1-3.5mm |

|

||

Nail length range |

40-90mm |

||||

Nail making speed |

1450pcs/min |

||||

Rated power |

10kw |

||||

Dimensions |

2060*980*1150mm 2000*1400*500mm

|

||||

Weight |

2100kg |

||||

FFI-SH-002

Super High Speed Nail Making Machine

|

Nail dia. range |

2.8-4.2mm |

|

||

Nail length range |

40-120mm |

||||

Nail making speed |

1050pcs/min |

||||

Rated power |

10kw |

||||

Dimensions |

2060*980*1150mm 2000*1400*500mm

|

||||

Weight |

2360kg |

FFI-SH-003

Super High Speed Nail Making Machine

|

Nail dia. range |

2.0-3.0mm |

|

||

Nail length range |

38-80mm |

||||

Nail making speed |

1650pcs/min |

||||

Rated power |

10kw |

||||

Dimensions |

2060*980*1150mm 2000*1400*500mm

|

||||

Weight |

2100kg |

Characteristics

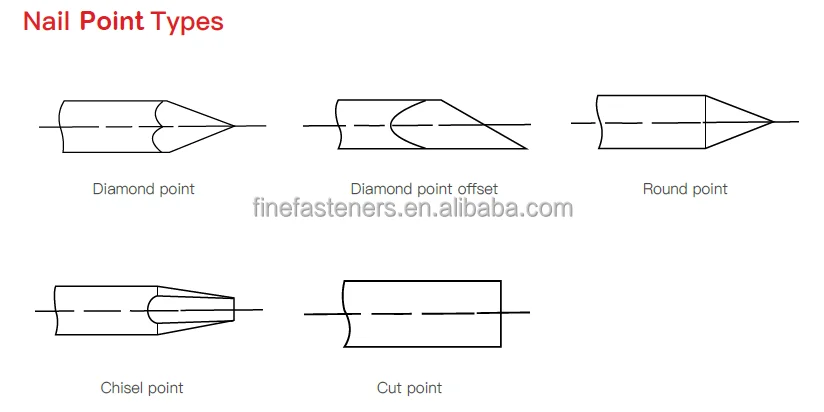

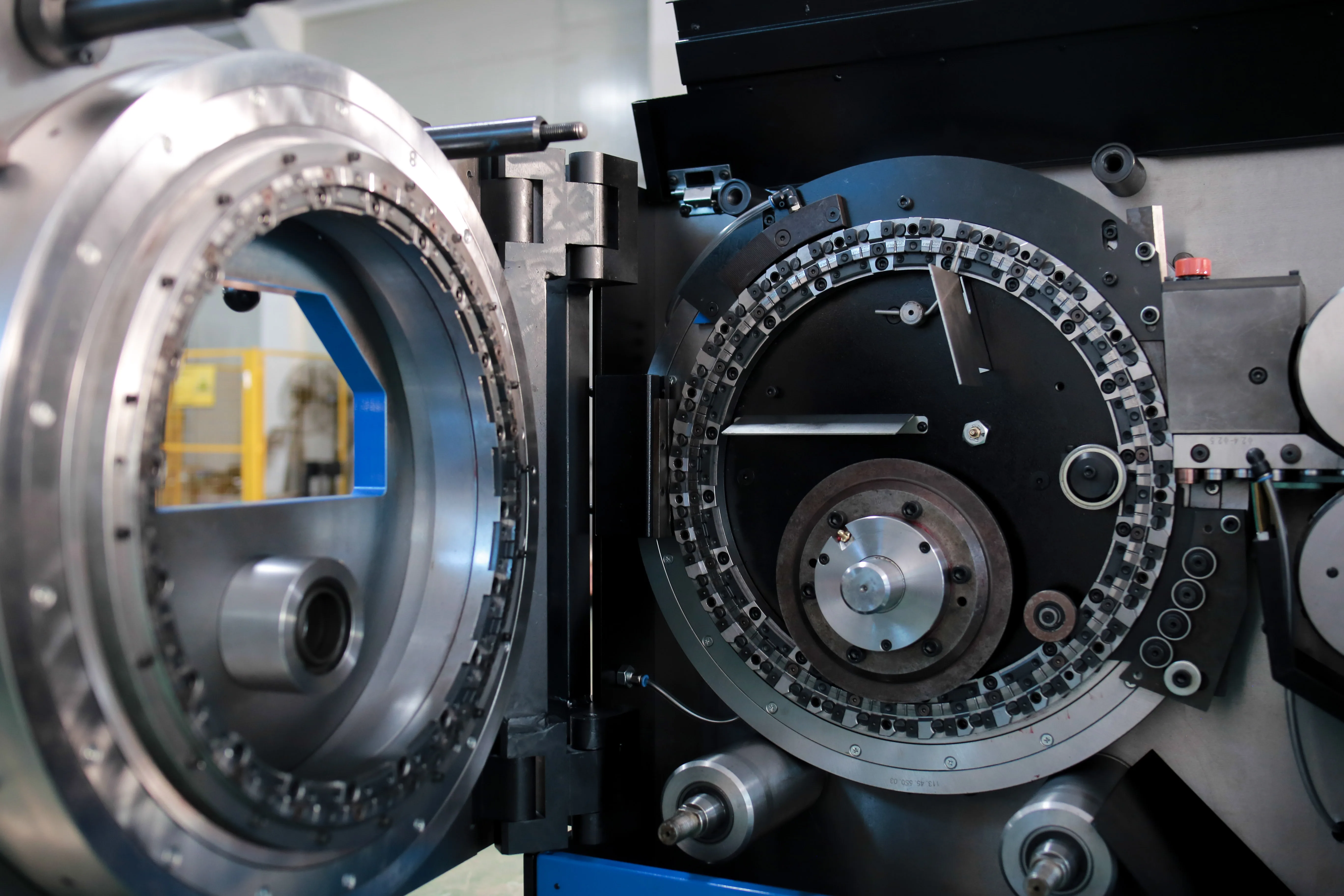

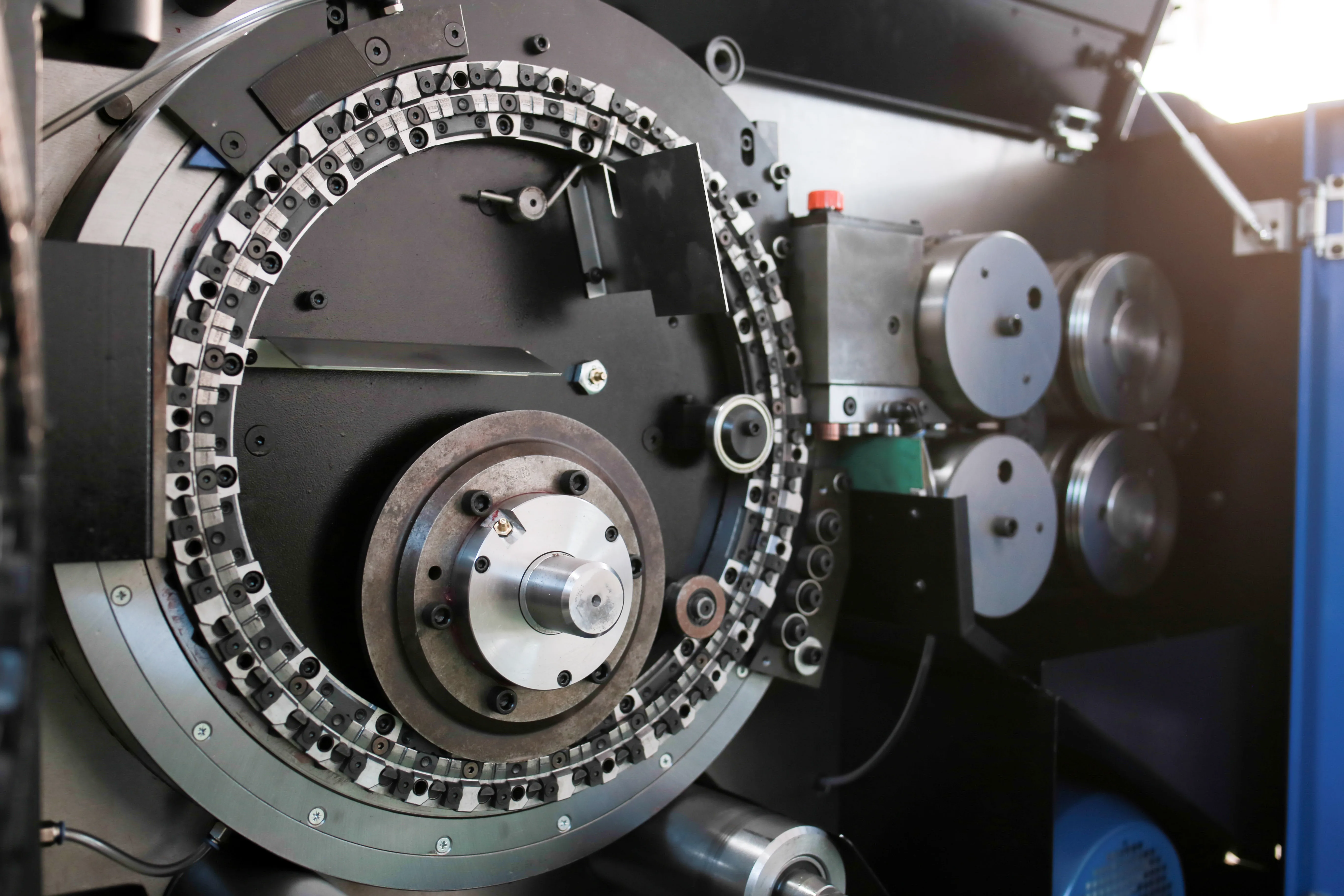

Supper High Speed Wire Nail Making Machine is our new design third generation type, it is different from traditional nail making machine, it can install the Nail counter to calculate the nails quantity, and also its max speed can reach 1650pcs/min. The nails(nails caps, nails point) produced by high speed nail making machine adopts the method of one time forming in mould, which make the nails very good quality, and also its shape is more neat and beautiful.

With the development of society, super high speed nail making machine technology is more mature, easy operation, labor saving, less land occupation, which greatly reducing production costs and increasing production efficiency. one high speed nail making machine capacity is same as around 8-10 sets common type nails making machine. In China, recently many nails factory start to adopt the super high speed nail making machine replace the traditional nails making machine.

Spare Parts

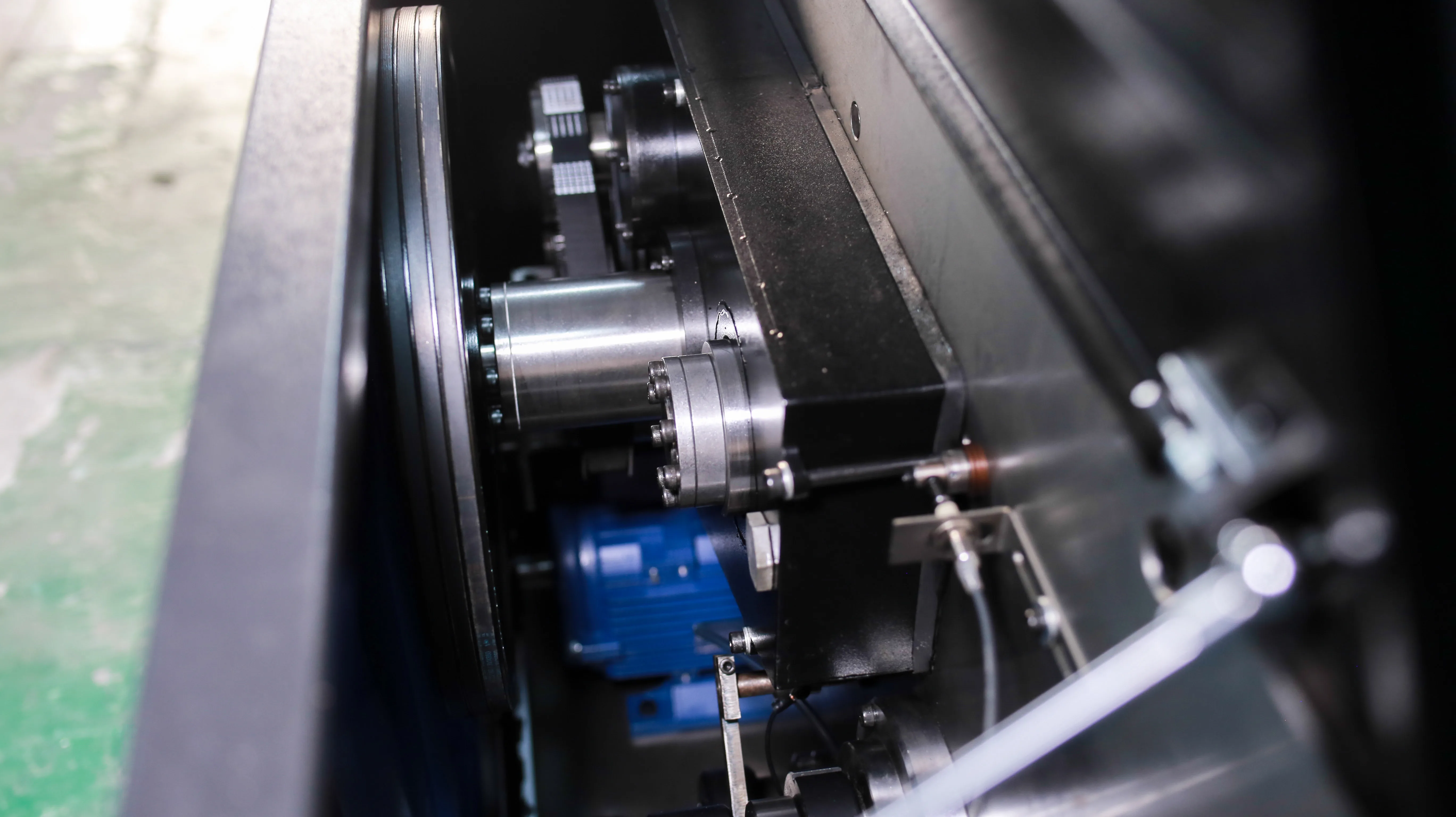

If only adjust the length of nails and keep the same wire diameter. 3-5 minutes is enough. If the nail diameter also need to be changed, then around 20 minutes will be needed for adjusting the feeding unit and gripping dies.

2. The lifespan for nail cutters, gripping dies and punches. ---->

Normally two months. It depends on the operator’s proficiency

3. The material for nail cutters, gripping dies and punches. ---->

Tungsten Carbide with alloy steel.

4. If there is some problems during machine running, what technical support can be provided? ---->

Video technical support and online service can be provided.

5. The tolerance for nail length ---->

± 0.25mm.

6. Installation service ---->

We can send engineers to your company for machine installation. The round trip flight tickets, local transportation, local accommodation should be paid by your company. Engineer service charge is US$100/day.

EN

EN