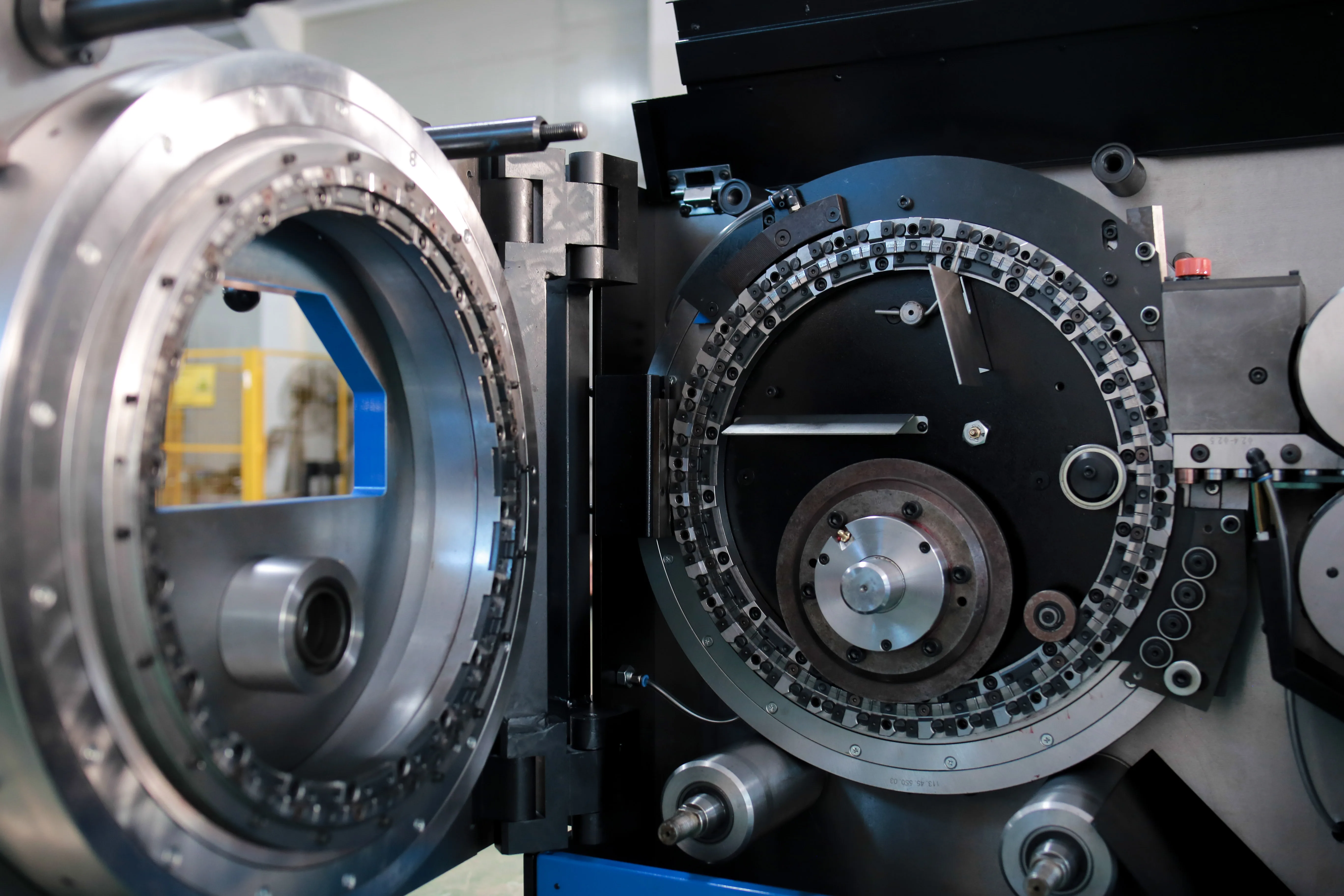

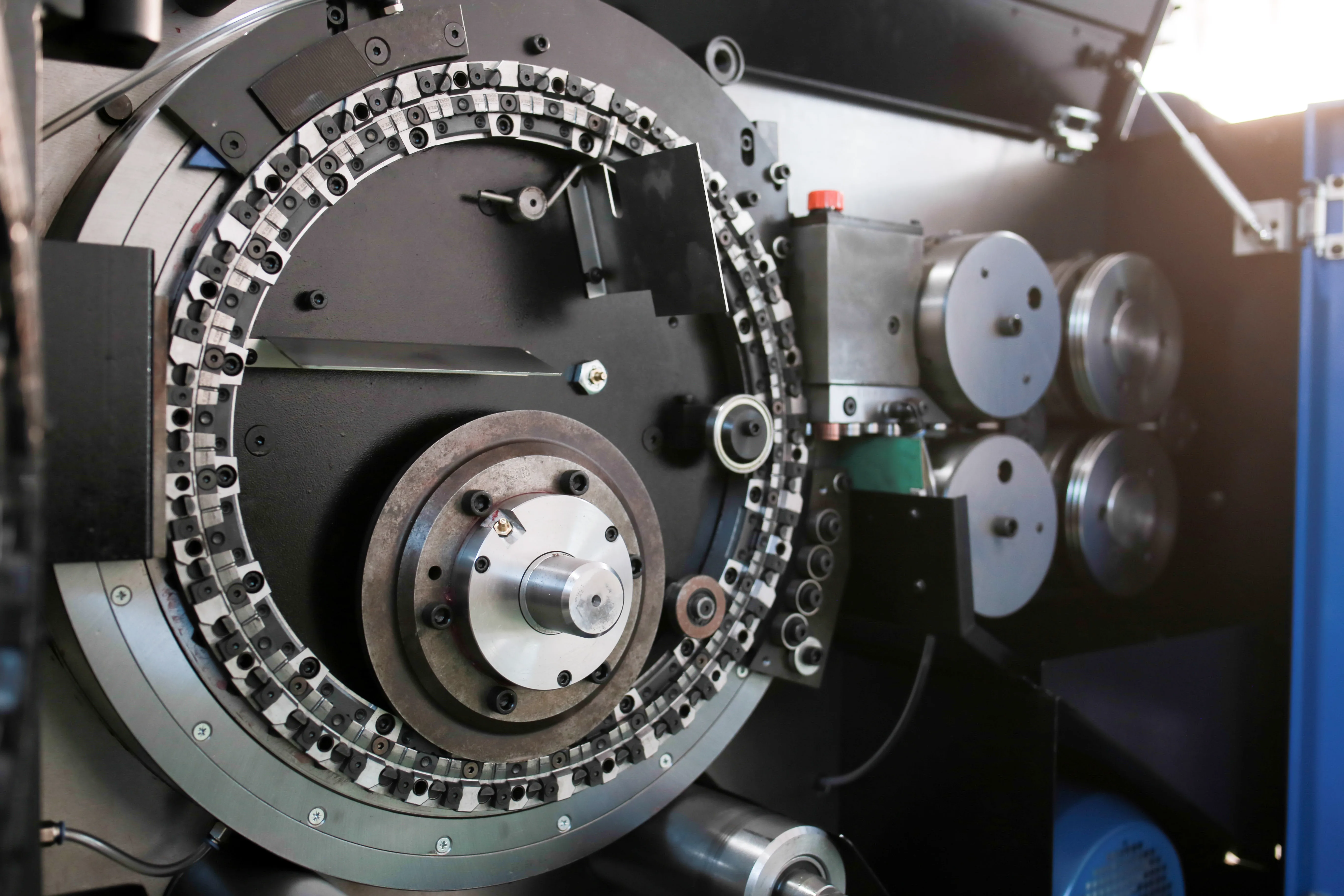

Product Description

The FFI Automated 80 Clutching Passes away are an amazing and unit that is supply that is versatile, effective and exact clutching solutions for market specialists. These passes away make the clutching procedure simpler and much more effective whether used for metalworking, auto environment up or other kind of production.

The FFI Automated 80 Clutching Passes away are adeptly developed from excellent products that do not simply assured a thing that is plain is resilient furthermore assurance efficiency that is optimal. They have really been supposed to hold an assortments that is large of with simpleness and accuracy, while maintaining the protection and safety associated with drivers. This implies they have been well matched for present in countless businesses looking business holds that hold limited in addition to help keep up use that is constant their holds.

The Automated 80 Clutching Passes away work progressed degree technologies that are modern create them fast and direct to utilizes. They normally have actually been filled with automated, programmable systems that make it possible for quick and smooth procedures, manufacturing them perfects for those that demands end that is quick while maintaining an also that is clearly a large amount of. These are typically operate on a method that is pneumatic enables smooth and energy that is consistent's clutching.

The FFI Automated 80 Clutching Passes away are likewise flexible within their abilities. These are usually developed to keep settle or curved reports of varied sizes and shapes, and appropriate use by having a real quantity of items consisting of light weight aluminum, metal, and various other steels. This is the reason them perfects for utilizes in applications where there is a prerequisite for versatility and flexibility.

Furthermore, the Automated 80 Clutching Passes away from FFI have actually a make that is guarantees that are small of utilize and transportability. The density enables drivers to function them well-suited for lots of settings up, installments, and maintenance that is basic using them in restricted areas, production.

The FFI Automated 80 Clutching Passes away are an remedy that is great those who efficiency that is well worth safety, and rate of their operate. They really are a reasoning that is forward that is technical supply an inexpensive and effective fix for clutching jobs. An accuracy is provided them perfect for people who need high degrees of accuracy by them hold which is unrivaled by old-fashioned clutching services, manufacturing. Today effort the FFI Automated 80 Clutching Passes away and go through the advantages of automation in clutching jobs.

Model No./Name |

Specification |

||||

FFI-SH-001

Super High Speed Nail Making Machine

|

Nail dia. range |

2.1-3.5mm |

|

||

Nail length range |

40-90mm |

||||

Nail making speed |

1450pcs/min |

||||

Rated power |

10kw |

||||

Dimensions |

2060*980*1150mm 2000*1400*500mm

|

||||

Weight |

2100kg |

||||

FFI-SH-002

Super High Speed Nail Making Machine

|

Nail dia. range |

2.8-4.2mm |

|

||

Nail length range |

40-120mm |

||||

Nail making speed |

1050pcs/min |

||||

Rated power |

10kw |

||||

Dimensions |

2060*980*1150mm 2000*1400*500mm

|

||||

Weight |

2360kg |

FFI-SH-003

Super High Speed Nail Making Machine

|

Nail dia. range |

2.0-3.0mm |

|

||

Nail length range |

38-80mm |

||||

Nail making speed |

1650pcs/min |

||||

Rated power |

10kw |

||||

Dimensions |

2060*980*1150mm 2000*1400*500mm

|

||||

Weight |

2100kg |

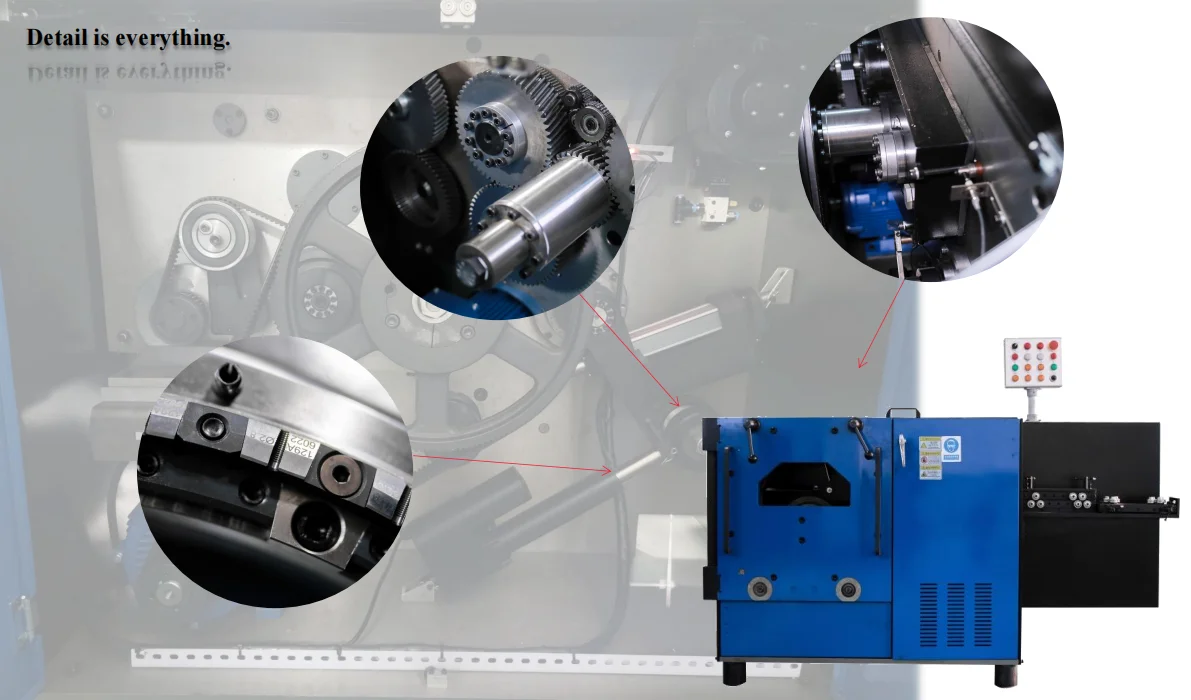

Characteristics

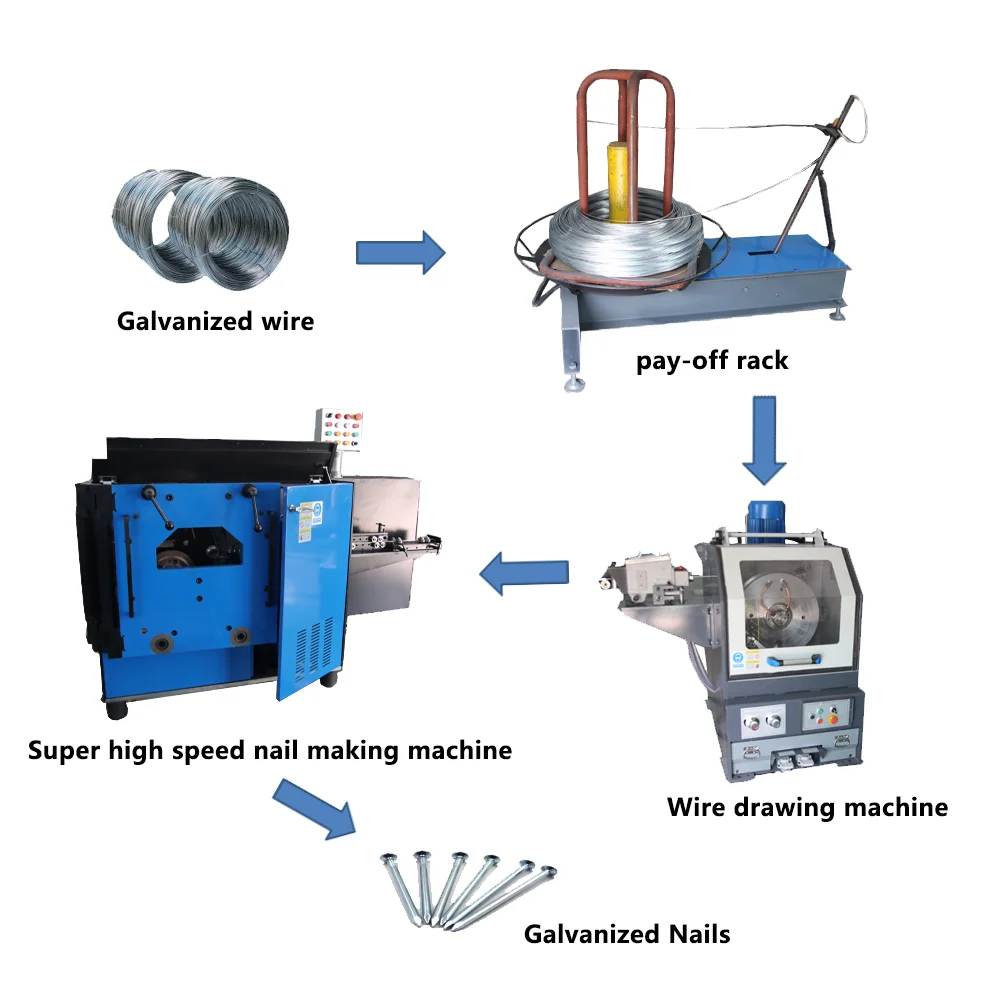

With the development of society, super high speed nail making machine technology is more mature, easy operation, labor saving, less land occupation, which greatly reducing production costs and increasing production efficiency. one high speed nail making machine capacity is same as around 8-10 sets common type nails making machine. In China, recently many nails factory start to adopt the super high speed nail making machine replace the traditional nails making machine.

Customized Color and Spare Parts

If only adjust the length of nails and keep the same wire diameter. 3-5 minutes is enough. If the nail diameter also need to be changed, then around 20 minutes will be needed for adjusting the feeding unit and gripping dies.

2. The lifespan for nail cutters, gripping dies and punches. ---->

Normally two months. It depends on the operator’s proficiency

3. The material for nail cutters, gripping dies and punches. ---->

Tungsten Carbide with alloy steel.

4. If there is some problems during machine running, what technical support can be provided? ---->

Video technical support and online service can be provided.

5. The tolerance for nail length ---->

± 0.25mm.

6. Installation service ---->

We can send engineers to your company for machine installation. The round trip flight tickets, local transportation, local accommodation should be paid by your company. Engineer service charge is US$100/day.

EN

EN