The Rebar Thread Rolling Machine - A Revolutionary Tool for Construction

Introduction:

The FFI rebar thread rolling machine is a powerful tool has revolutionized the construction industry, rendering it faster, safer, and more efficient. This machine can roll threads on rebar, critical for looking jobs for reinforcement of concrete structures. We shall explore the benefits, innovation, protection, use, how-to-use, services, quality, and applications with this fantastic tool.

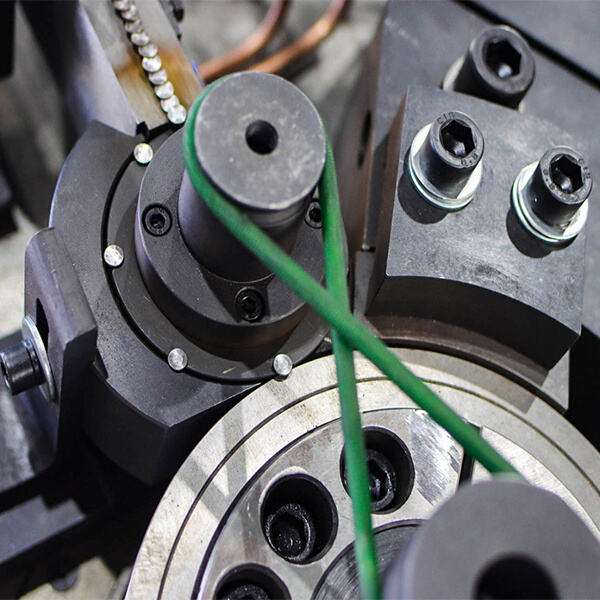

Among the key advantages of the rebar thread rolling machine is the capacity to accurately deliver high-quality threads and quickly. This FFI thread rolling machine can create threads of varied sizes and specifications, like imperial threads and metric, that makes it versatile and adaptable to different construction. Furthermore, the machine's automation feature reduces the need for manual labor and, consequently, minimizes the possibility of accidents in construction web sites.

The rebar thread rolling machine is just an item of cutting-edge innovation. It incorporates advanced tech enhances its functionality and performance. The rate, torque, and thread depth as an example, the FFI roller threading machine has a built-in electronic display displays the operator. This particular feature ensures the precision and precision of the threads produced while creating the operation more cost-effective.

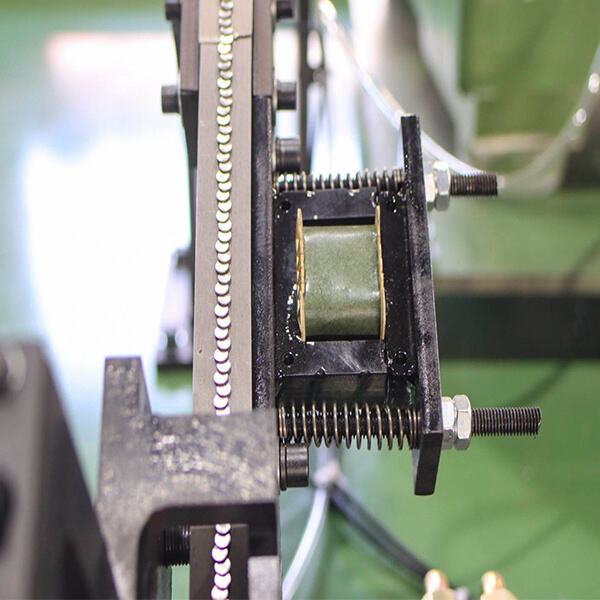

Security was vital in just about any construction venture. The rebar thread rolling machine was made utilizing the safety when it comes to operator in your thoughts. The FFI cnc thread rolling machine features a safety guard that protects the operator from connection with rotating parts. Also, the machine's automatic feeding system helps take care of the operator's hands not even close to areas and this can be dangerous.

Utilizing the rebar thread rolling machine try relatively uncomplicated. The first step should be to discover the appropriate dies adjust the thread depth and size in the electronic display. The operator then has to put the rebar in the machine's input slot, and the machine will automatically feed the bar and begin the rolling procedure. The FFI flat thread rolling machine will stop immediately if the desired thread size is attained.

Many of us of experts is specialized in supplying the amount highest of way consumers and quality-control rigorous. We are prepared to accept tasks that could be custom-designed. Call us with any concerns you've got, whether regarding picking a product from our catalog or solutions that are getting issues that are technical will likely to be practical. We shall never ever overlook the maxims of great Person Fine item, Fine Service, and we shall do our best meet your requirements.

Our products have acquired CE certifications having a quality top. Our consumers have really respected and recognized our item both in the residence genuine offshore. This is really is composed of South and North Americas Europe, Africa and South Africa, Middle East and Asia. We've been somebody that definitely a trustworthy of nail and range manufacturers for a while that definitely a lengthy to the proficient exceptional at competitive costs, and provides answer expert.

The corporation is focused on employee development and education manufacturing effectiveness seriously plain things technical getting dramatically improved. In inclusion, you can expect assisting our lovers organized their certain production outlines when you look at the couple last of Mexico, Brazil, Poland, Czech, Ukraine, Russia, Saudi Arabia, Libya,

FFI Machinery devotes it self making the absolute most durable and equipment that definitely a advanced. Select FFI equipment and produce incomparable value. Fine Fasteners Industry Co. , Ltd. is supplier experienced is worldwide associated with analysis and development, product sales and maintenance of One Sp Nail Production Line, Wire Processing Equipment, Welding Electrode Production Line, MIG Welding Wire Production Line as well as other related equipment for fasteners. We not just provide transport easy, but additionally mindset open-minded.

The operator has to follow group of actions to use the rebar thread rolling machine. The first step to prepare the machine together with dies, ensuring they may be free from any dirt and debris. Then, the operator must adjust the machine's thread level and size, with regards to the project's specifications. Once the dies have been in destination, the operator loads the rebar into the machine's input slot and waits for the machine to start rolling the thread. The FFI small thread rolling machine will minimize automatically if the length that you need is reached.

The rebar thread rolling machine requires regular repair to work optimally like most other machine. An user was furnished by producer manual that describes the maintenance procedures that ought to be properly used. The provider of FFI thread rolling equipment often include lubrication, cleaning, and inspection of components for indications of damage. Furthermore, if you will find any pressing issues with the machine's functioning, operators can contact the maker's customer care to acquire assistance.

The grade of the rebar thread rolling machine was top-notch. The FFI high speed thread rolling machine is made from top-notch durable content and robust. Its quality guarantees it might withstand the harsh working of construction sites. Furthermore, the machine's efficiency is exceptional, regularly delivering high-quality threads that meet with the venture's criteria.