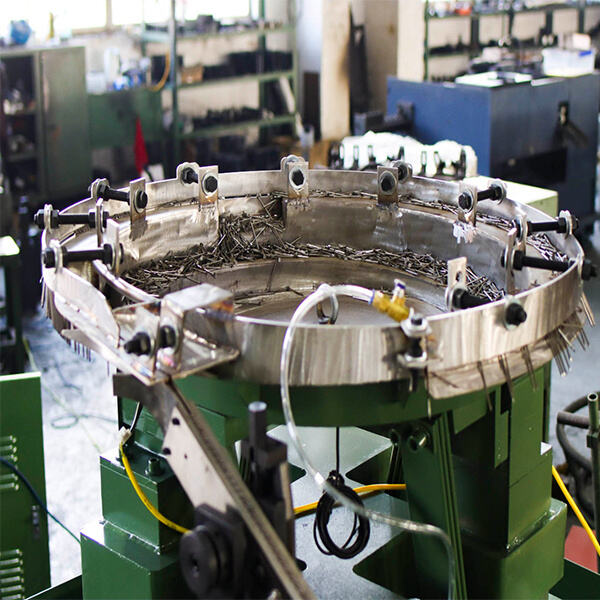

Thread rolling machines is an innovative product creates threaded parts by pushing a workpiece against a rotating, hardened die. The thread rolling machine flat die is a versatile FFI instrument can be utilized in a variety of ways to save time, effort, and resources. We’ll explore the importance of thread rolling machines and the way they could be utilized for different applications.

The thread rolling machine flat die has some FFI advantages other ways of creating threaded parts. It could be utilized to produce threads in many thread rolling machine materials, including metals, plastic materials, and composites. Thread rolling machines create a higher degree of, durability, and persistence, making them perfect for mass manufacturing of identical parts.

The thread rolling machine flat die is certainly a revolutionary FFI product uses advanced level manufacturing ways create threaded components quickly and efficiently. Their unique roller threading machine design allows to create precise, high-quality threads that was resistant to put on, corrosion, as well as other kinds of damage. thread rolling machines can be versatile and may be used of the wide range of applications, assisting to cause them to an excellent investment company trying to reduce manufacturing expenses and improve efficiency.

Security is a top issue it comes down seriously to using thread rolling machines. These FFI machines are loaded with safety features such as guards, emergency stop buttons, and automated shut-offs. Users must also follow appropriate protection, such as wear protective gear avoiding free clothing or precious jewelry that may easily get caught in the thread roller machine. Utilizing the precautions being best can be used safely and effectively.

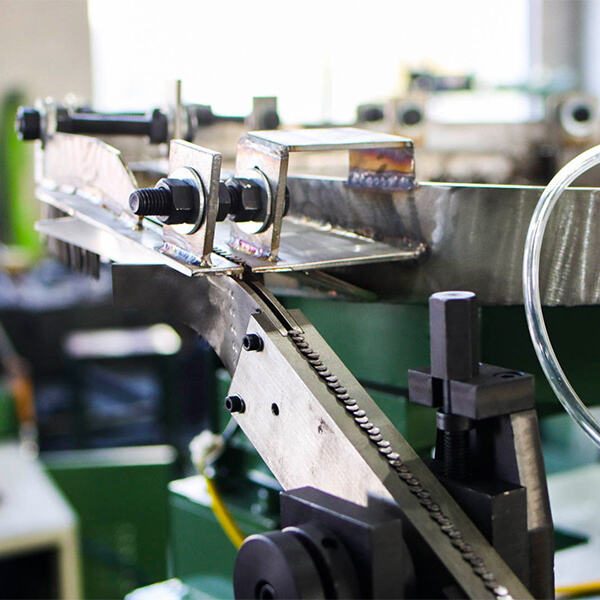

Using a thread rolling machine flat die are reasonably simple. First, the workpiece is inserted into the FFI machine, and the die is positioned against it. The thread roller dies machine is then triggered, and the die try rotated, which in turn causes it to press contrary to the workpiece and form threads. Once the threads are formed, the workpiece is taken from the machine, and the threads are checked for precision and quality.

Kenya, Turkey, Sri Lanka, Indonesia and several other items.We offer assisting our followers in order make his or her manufacturing outlines in the few absolutely past of Mexico Brazil Poland Czech Ukraine Russia Saudi Arabia Libya Kenya Turkey Sri Lanka Indonesia etc.

FFI Machinery devotes it self making one of the most durable and gear advanced. Choose FFI machines, and also you might get value unbeatable. Fine Fasteners Industry Co. , Ltd. , being a provider international is active in the research and development, product sales and service of 1 Sp Nail Production Line, Wire Processing Equipment, Welding Electrode Production Line, MIG Welding Wire Production Line as well as other many other gear that definitely a fastener-related. We offer not transport just efficient but in addition friendly and mindset that definitely a open-minded.

Our things have already been provided CE certifications because of their exemplary quality. Our clients have really recognized and respected our item when you look at the residence true abroad. They feature South and North Americas Europe, Africa and South Africa, Middle East and Asia. We've a thing superior competitive prices, along with our option expert have already been a lover that definitely a protracted of nail and cable manufacturing services.

In the quest for rigid quality-control and a approach thoughtful customer support, our experienced staffs continuously keep carefully the interaction window ready accept our dear customers. We would want to learn about custom-designed projects. You can easily call us for just about any inquiries you could be having, whether it's about selecting a item from our catalog or solutions that are acquiring issues that are technical will meet your requirements. We intend continue stick to the fundamentals of ours': Fine person, good item Fine service, so we'll always do our utmost.