Product Description

The latest silver welding electrodes making machines equipment production line factory price

Product Overview

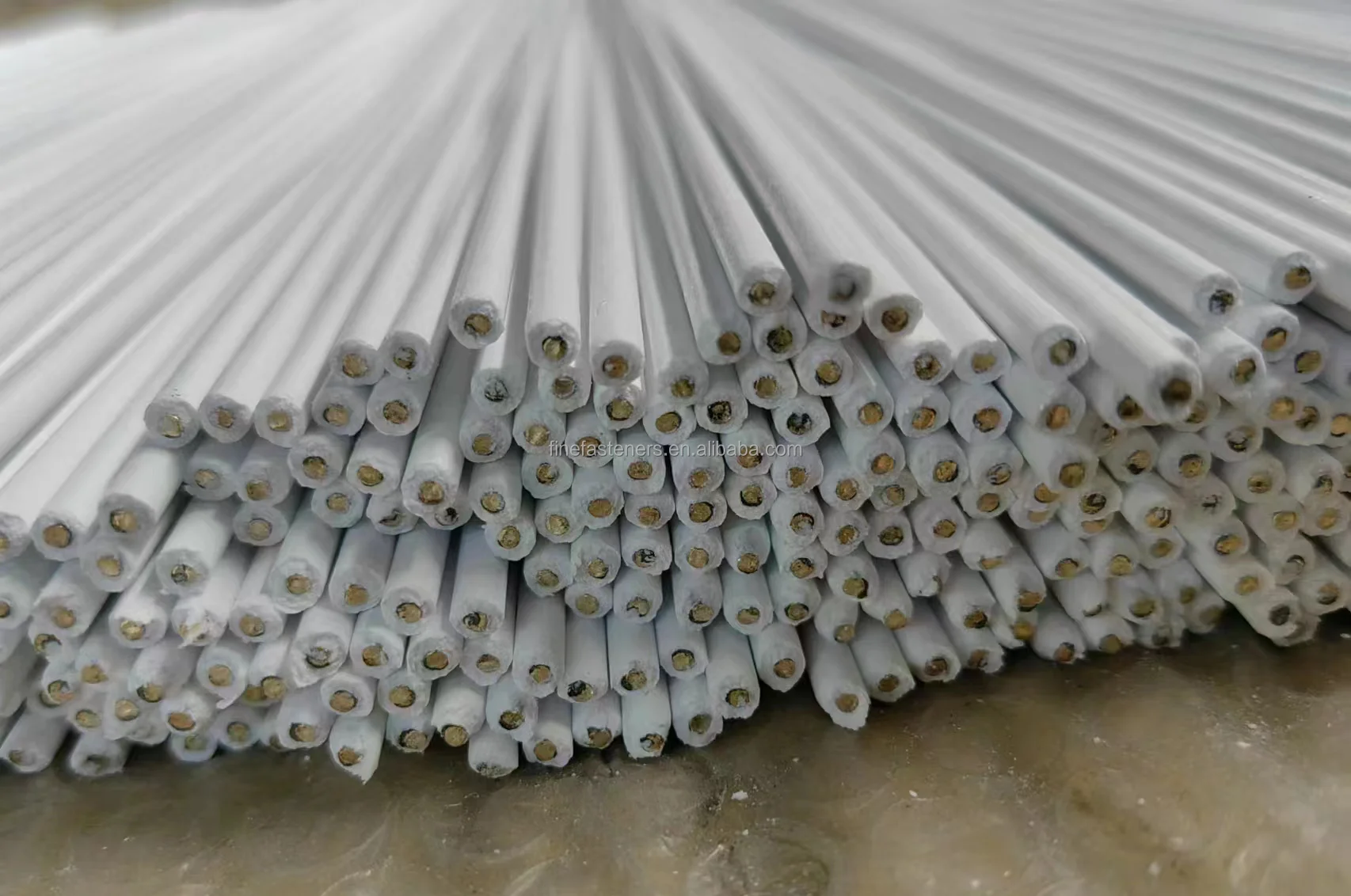

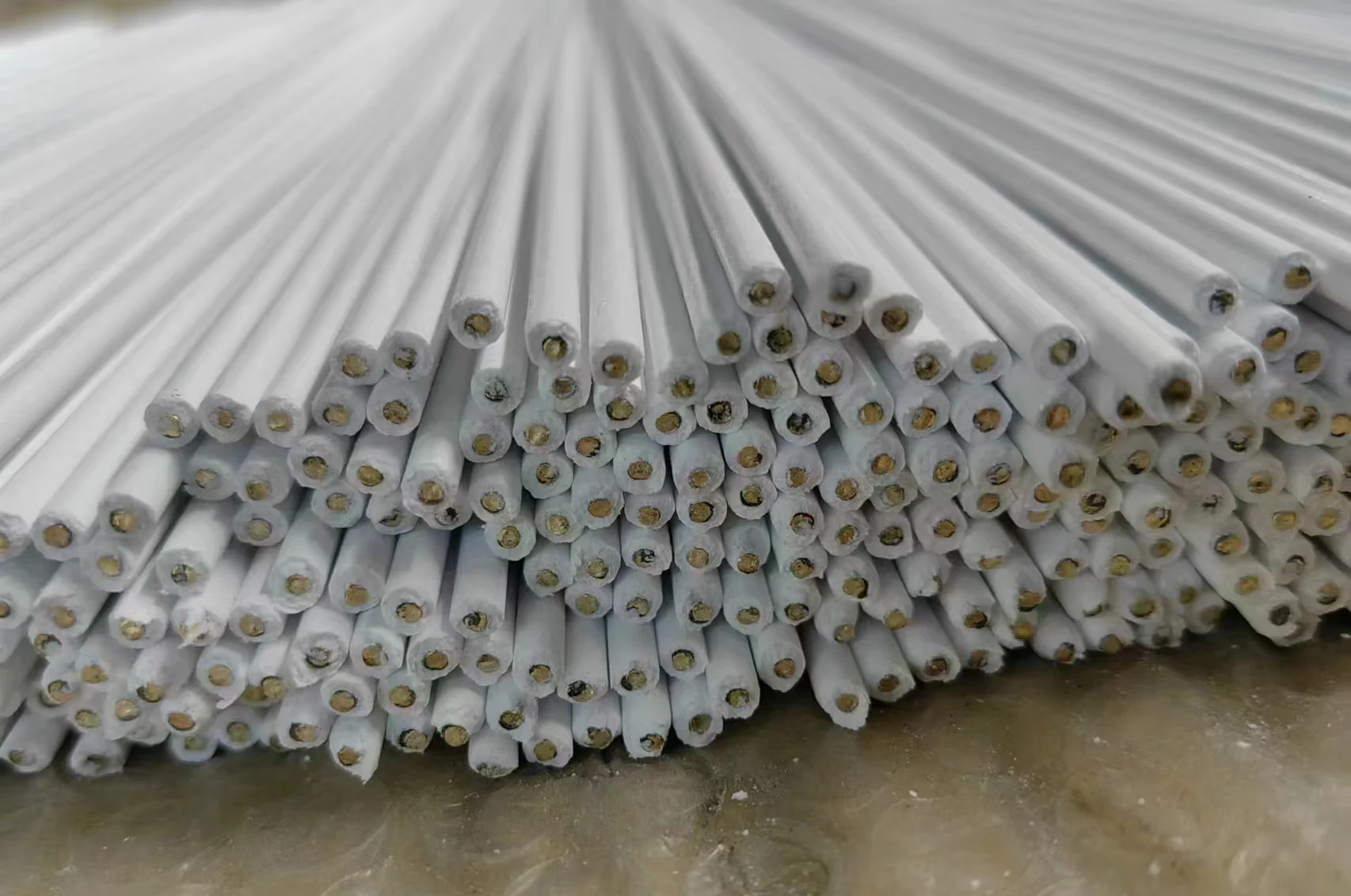

Silver welding rod is a kind of welding rod containing silver components, which is used for welding and repairing metals. Because silver has excellent electrical and thermal conductivity, silver welding rods are often used for welding electronics, electrical appliances and precision instruments. Its characteristics include: High electrical and thermal conductivity: Silver has good electrical and thermal conductivity, which enables it to quickly conduct heat during welding and improve welding efficiency. Excellent wettability: Silver welding rods easily wet with the substrate during welding to form a strong welding joint. High corrosion resistance: Silver has strong corrosion resistance, which makes the joints welded with silver welding rods stable even in harsh environments. Low melting point: Silver welding rods have a low melting point and are suitable for welding heat-sensitive materials.

Design specification 1. Output: 500-600kgs/ 8hour(take the Φ1.5mm’s welding electrode for example)

2. Delivery time: 60day 3. Size of the production: Φ1.5*500mm, Φ2.0*500mm, Φ3.0*500mm.

4. Production electrode type: Silver welding electrode

5. Workers: 4-5 workers, 1 assistant.

6. Transportation:1*20GP

7. Price excluding equipment wearing parts 8. HS CODE:84633000

9.Power supply: 380V,50HZ (415V,50HZ or Customized)

Customer test report after inspection

Flow Chart:

PRODUCT SPECIFICATIONS

|

No.

|

Equipment

|

Function

|

|

1

|

Descaling machine

|

Remove the dust from the wire.

|

|

2

|

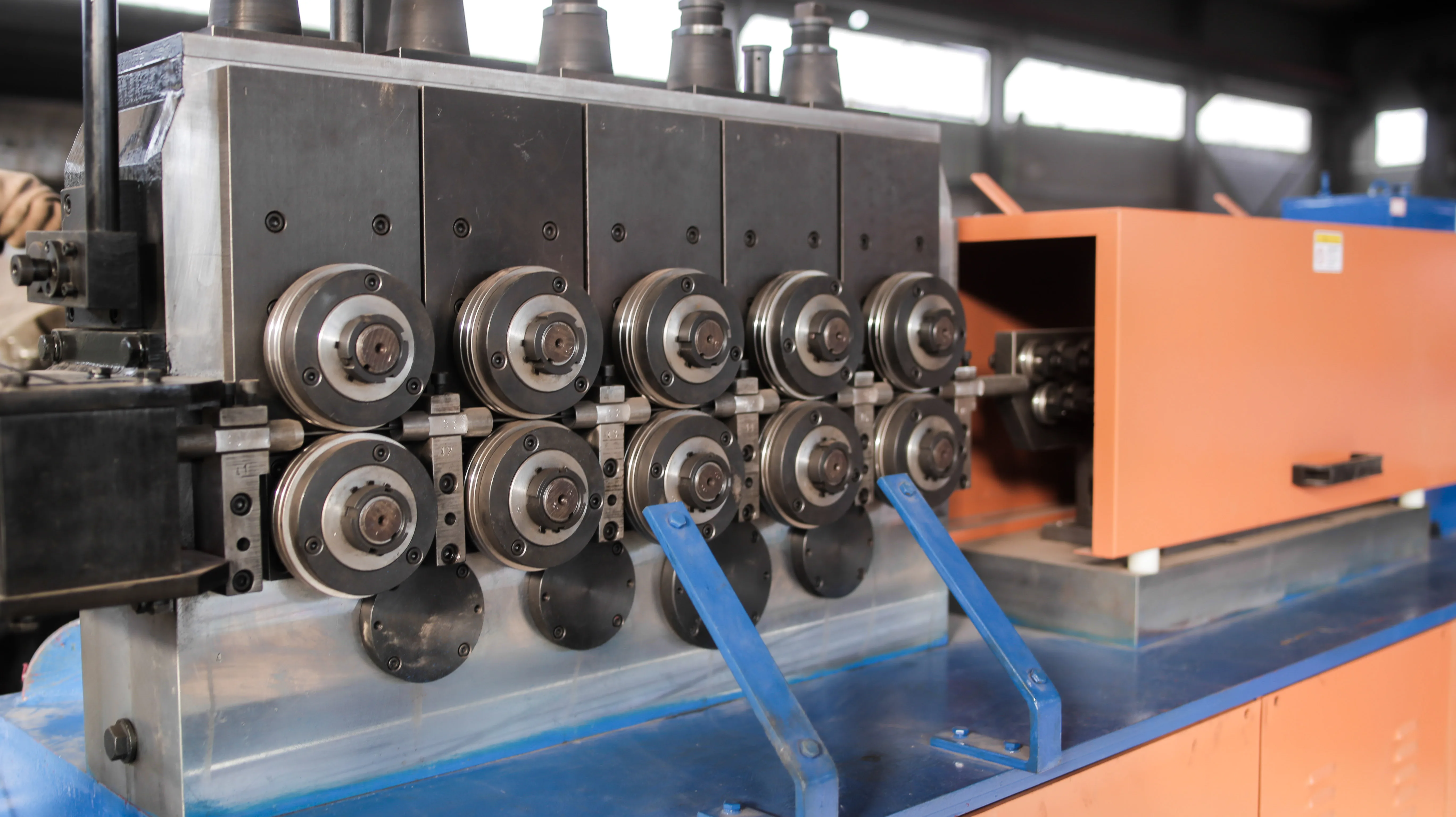

Tip roller

|

Sharpen the tip of wire.

|

|

3

|

Butt-welding machine

|

To weld the wire tips when 1 roll is finished.

|

|

4

|

Wire drawing machine

|

To draw the wire into diameter needed.

|

|

5

|

Single arm crane

|

To lift the wires.

|

|

6

|

Wire cutting machine

|

To cut wire into size.

|

|

7

|

Mixing Machines Double "S" Type

|

Mix the powder for coating.

|

|

8

|

Silicate Mixer

|

Silicate stirring barrel is special for stirring liquid silicate.

|

|

8

|

Wire-feed machine

|

Wire supply.

|

|

9

|

Hydraulic powder coating machine

|

Coat the mixed powder onto the wire.

|

|

10

|

Head-Tail Grinder machine

|

To grind the head and tail into standard shape.

|

|

11

|

Electrode eccentric measuring Instrument

|

Eccentric checking.

|

|

12

|

Control panel for spiral line

|

Main control of electricity.

|

|

13

|

Auxiliary line machine

|

Internal conveying.

|

|

14

|

Box type hot air circulation drying furnace(electricity)

|

Drying the coating on the core.

|

|

15

|

Words printer

|

Printing dates or brand name.

|

|

16

|

Shrink packaging machine

|

Plastic packing.

|

|

17

|

Strapping machine

|

Wrapping.

|

|

18

|

Reclaiming machine

|

Peel the coating off.

|

|

19

|

Straightening machine

|

Straighten the wire.

|

|

20

|

Vibrating screen

|

To filter the recycled coating.

|

Company Profile

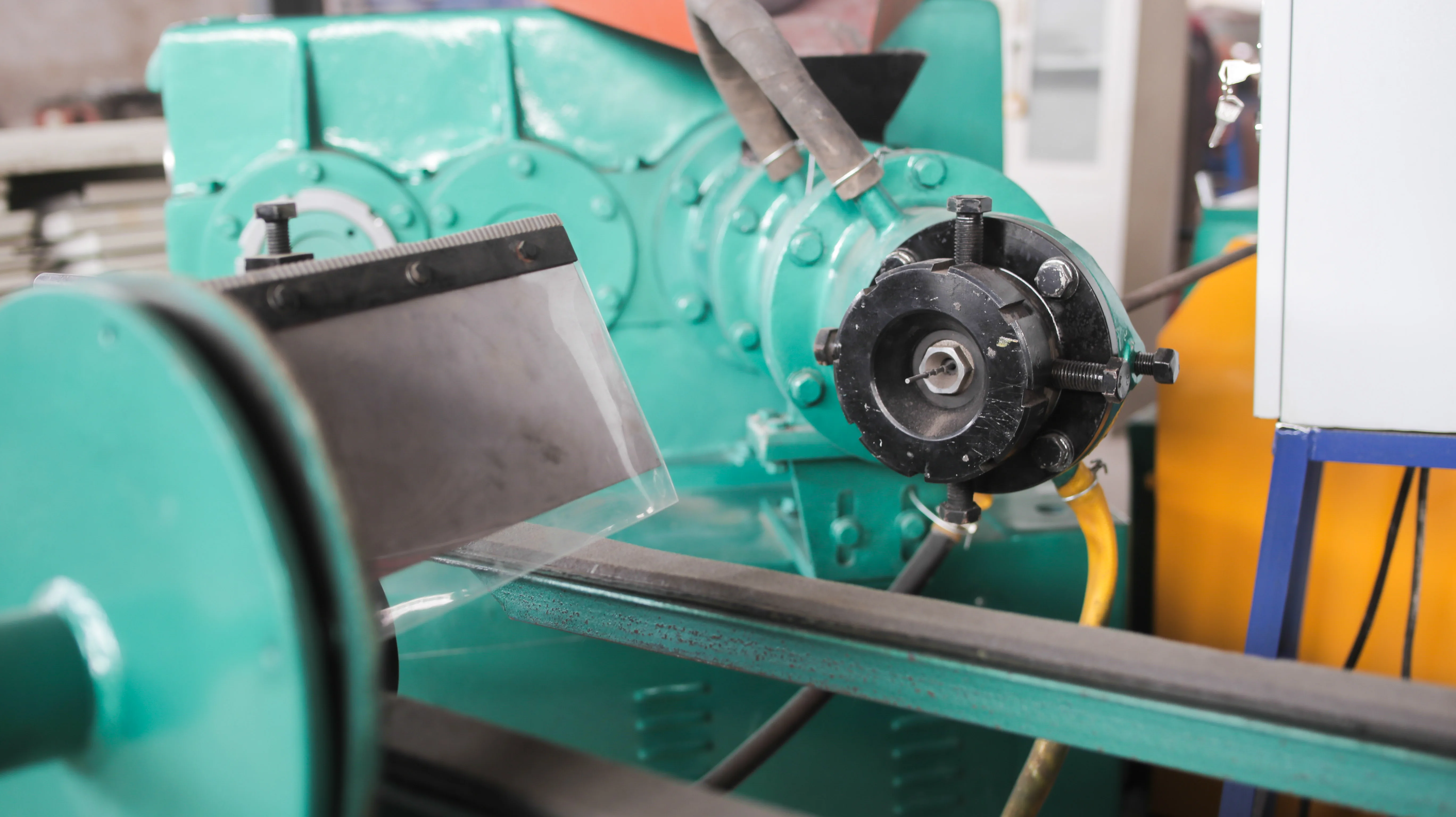

Fine Fasteners Industry Co.,Ltd (FFI) has been a super manufacturer and exporter of the spiral coated electrode production line series, hydraulic coated mechanical and electrical welding rod production line series has excellent manufacturing equipment, advanced production technology, product quality is stable and high production efficiency, high speed, and make the coating thickness uniformity, smooth, dense, the advantages of stable quality,

also can make the pressure of electrode coating, transfer, grinding head grinding tail, printing, drying and packing process to realize full mechanization and automation, such as is currently the major electrode production enterprise much-loved electrode device. Our company also supplies various types, specifications of welding rod production raw materials, to provide customers with one-stop service.Up to now our customers are spread in Europe, Asia, Africa, South Africa, Middle East and other countries & regions. With our superior quality, competitive price and professional service, we have gained great approval and satisfaction from customers globally.

We will continuously stick to the core principle of “Fine person, Fine product and Fine service” and offer the best equipment for customers through never-ending research and development. We are sincerely looking forward to working together with you to create a glorious future.

also can make the pressure of electrode coating, transfer, grinding head grinding tail, printing, drying and packing process to realize full mechanization and automation, such as is currently the major electrode production enterprise much-loved electrode device. Our company also supplies various types, specifications of welding rod production raw materials, to provide customers with one-stop service.Up to now our customers are spread in Europe, Asia, Africa, South Africa, Middle East and other countries & regions. With our superior quality, competitive price and professional service, we have gained great approval and satisfaction from customers globally.

We will continuously stick to the core principle of “Fine person, Fine product and Fine service” and offer the best equipment for customers through never-ending research and development. We are sincerely looking forward to working together with you to create a glorious future.

Customer Photos

Why Choose Us

1 Our company has professional installation & commissioning teams, we will install and debug the production

line at the customers’ place until the equipment produces qualified products.

2 We supply spare parts all the year round. The guarantee of equipment is one year.

3 We are responsible for the technical consultation and service all the year around and help to solve all kinds

of technical problems at any time.

4 We will help customers do the consignment and the relevant procedure for import and export.

5 Our company supply the information of the seller for all kinds of raw materials and relevant information for free.

line at the customers’ place until the equipment produces qualified products.

2 We supply spare parts all the year round. The guarantee of equipment is one year.

3 We are responsible for the technical consultation and service all the year around and help to solve all kinds

of technical problems at any time.

4 We will help customers do the consignment and the relevant procedure for import and export.

5 Our company supply the information of the seller for all kinds of raw materials and relevant information for free.

Packing And Delivery

EN

EN