Product Description

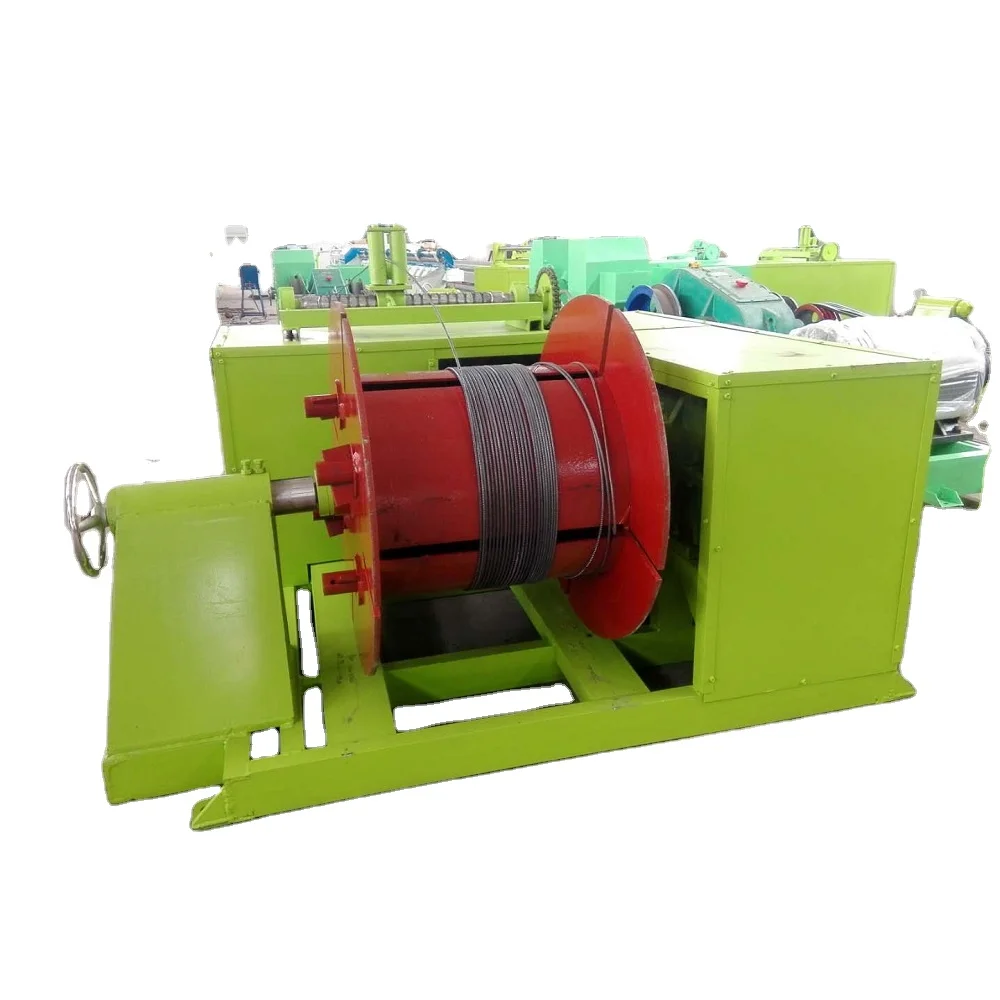

Pulley type wire drawing machine cheap price with water cooling system

Products Description

Product Paramenters

Usage and Features

The pulley wire drawing machine consists of main reducer motor, mould case, guiding wheel frame and general electrical motor control system. Each pot has JZT series or Y series motor and its own gear combination axis; the machine is drived by gears. The machine can automatically produce different specifications of products. The drawing pot work vertically. The rotational speed increases with the thinning and lengthening of the wire rods.

The pulley wire drawing machine consists of main reducer motor, mould case, guiding wheel frame and general electrical motor control system. Each pot has JZT series or Y series motor and its own gear combination axis; the machine is drived by gears. The machine can automatically produce different specifications of products. The drawing pot work vertically. The rotational speed increases with the thinning and lengthening of the wire rods.

Main Features

● Easy in installation and maintenance.

●Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

●Running in a high automatization and intellectualization,no pollution

●As the use of the frequency technology, changes in the larger context of parts of the compression ratio to meet the wide range of technology and high speed drawing.

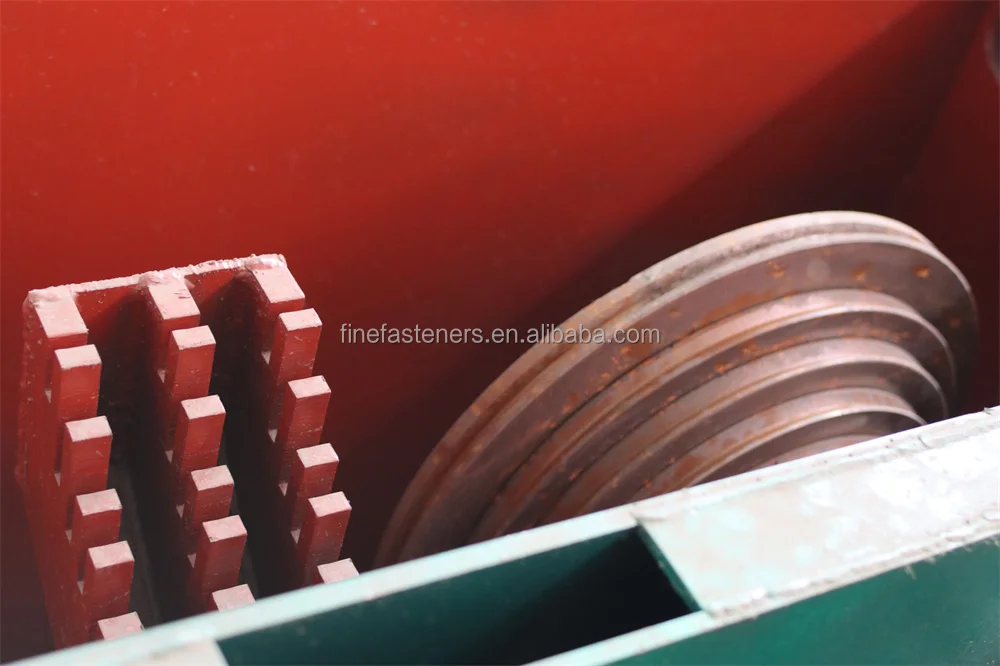

●Good cooling system, final wire quality is very good.

|

Type

|

560

|

550

|

450

|

350

|

|

Material Intensity

|

δb≥110kg/mm2

|

120kg/mm2

|

128kg/mm2

|

δb≤140kg/mm2

|

|

Max. Dia. Of Inlet Wire

|

6.5mm-4.4mm

|

6.5mm

|

4mm

|

2.6-1.5mm

|

|

Min. Dia. Of Outlet Wire

|

2.6mm-1.8mm

|

2.2mm

|

1.6mm

|

1.2-0.8mm

|

|

Block

|

1

|

1

|

1

|

1

|

|

Max. average condensation

|

0.3

|

20%

|

20%

|

21%

|

|

Total Condensation

|

78-88.5%

|

78%

|

77.90%

|

78%

|

|

Max. Speed of Block

|

245m/min

|

260m/min

|

280m/min

|

200m/min

|

|

Total Power

|

22/30kw

|

18.5/22kw

|

11/15kw

|

5.5/7.5kw

|

Accessory Equipment

|

Name

|

Model

|

Range of Dia.

|

|

Discharging Machine

|

|

|

|

Pointing Machine

|

FFI-F-96

|

6.5-1.5mm

|

|

Pointing Machine

|

FFI-F-80

|

3.5-1.0mm

|

|

Butt-Welding Machine

|

FFI-UN-10

|

8--2mm

|

|

Butt-Welding Machine

|

FFI-UN-3

|

6.5-1.5mm

|

|

Butt-Welding Machine

|

FFI-UN-1

|

3.5-1.0mm

|

|

Automatic Discharging Machine

|

FFI-XB-600

|

capacity 800kg

|

|

Automatic Discharging Machine

|

FFI-XB-360

|

capacity 400kg

|

|

I Type Spool Reeling Machine

|

FFI-SG-800

|

capacity 800kg

|

|

I Type Spool Reeling Machine

|

FFI-SG-630

|

capacity 500kg

|

|

Descaling Machine

|

FFI-SW650

|

|

|

Motorless Descaling Machine

|

with steel brush

|

|

|

Well Type Furnace

|

FFI-RJ-90-9

|

|

Compact and cost-effective

1:wire drawing in a single, compact unit

2:economic and user-friendly machine design with easy maintenance

3:left and right-hand versions for Non Ferrous

4:metal wires with the highest quality requirements

5:single wire path with no crossover effective single-wire drying

2:economic and user-friendly machine design with easy maintenance

3:left and right-hand versions for Non Ferrous

4:metal wires with the highest quality requirements

5:single wire path with no crossover effective single-wire drying

Company Information

Fine Fasteners Industry Co.,Ltd (FFI) has been a super manufacturer and exporter of nails and the related machines such as all types of wire drawing machine, nail making machine, wire collating machine, plastic and paper tape machine, thread rolling machine.Up to now our customers are spread in Europe, Asia, Africa, South Africa, Middle East and other countries & regions.We have become a long-term partner for many nail making and wire making factories and helped a number of nail and wire making plants establish their own production lines in past years.With our superior quality, competitive price and professional service, we have gained great approval and satisfaction from customers globally.

We will continuously stick to the core principle of “Fine person, Fine product and Fine service” and offer the best equipment for customers through never-ending research and development.

We are sincerely looking forward to working together with you to create a glorious future.

We will continuously stick to the core principle of “Fine person, Fine product and Fine service” and offer the best equipment for customers through never-ending research and development.

We are sincerely looking forward to working together with you to create a glorious future.

Certifications

Our Advantages

Advantages we have:

A. 20 years experiences in making nail machine.

B. Professional technical team and sales department for your service

C. Factory recognized by 'CE/FSC/ISO9001' and so on

D. 7*24 service for you.all the questions will be delay within 24 hours

Benefit you can get:

A. Stable quality ——Coming from good materials and technical

B. Lower price——Not the cheapest but the lowest at the same quality

C. Good service——Satisfactory service before and after sale

D. Delivery time——Quickliest factory direct delivery for mass production

A. 20 years experiences in making nail machine.

B. Professional technical team and sales department for your service

C. Factory recognized by 'CE/FSC/ISO9001' and so on

D. 7*24 service for you.all the questions will be delay within 24 hours

Benefit you can get:

A. Stable quality ——Coming from good materials and technical

B. Lower price——Not the cheapest but the lowest at the same quality

C. Good service——Satisfactory service before and after sale

D. Delivery time——Quickliest factory direct delivery for mass production

Customer Photos

EN

EN