Product Description

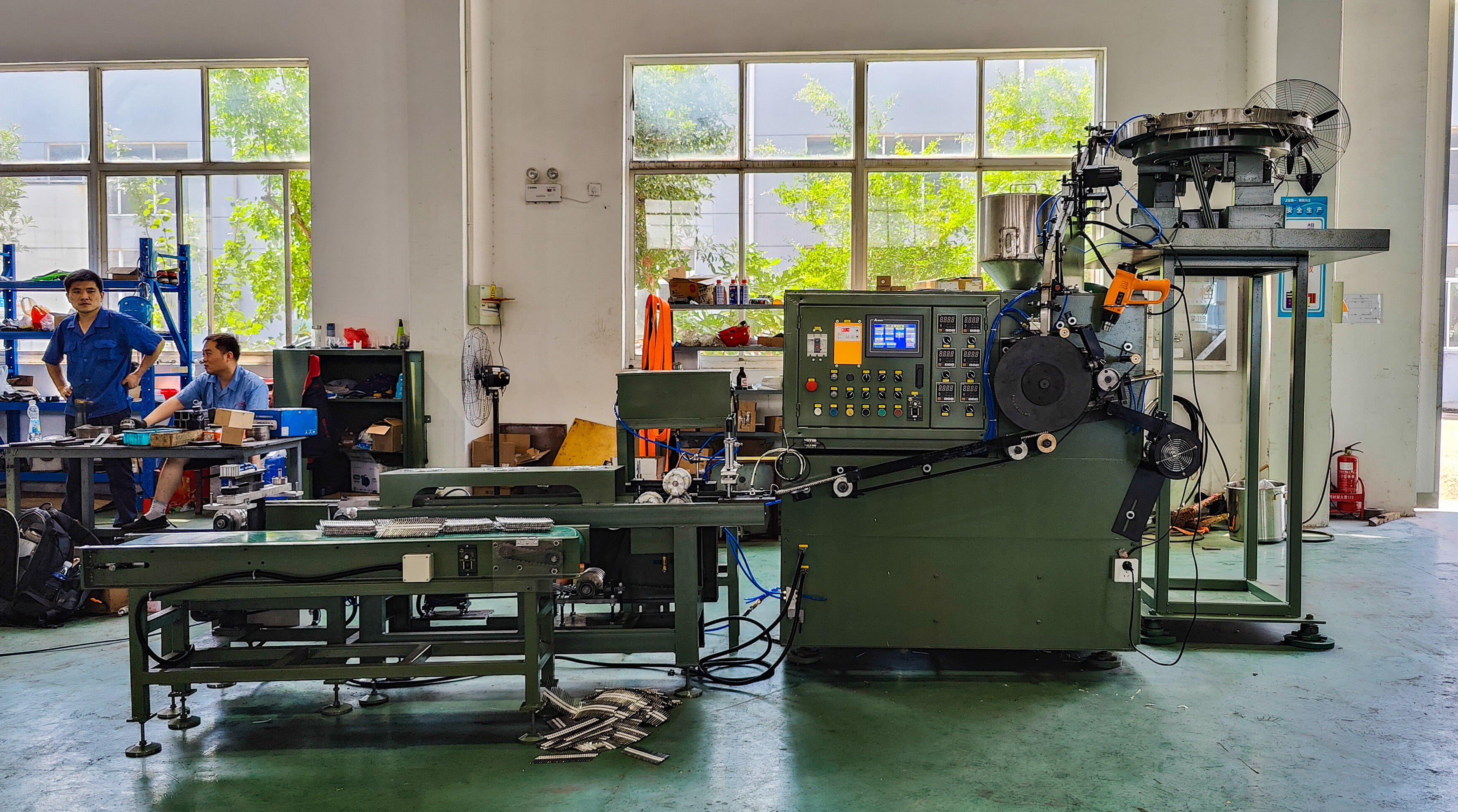

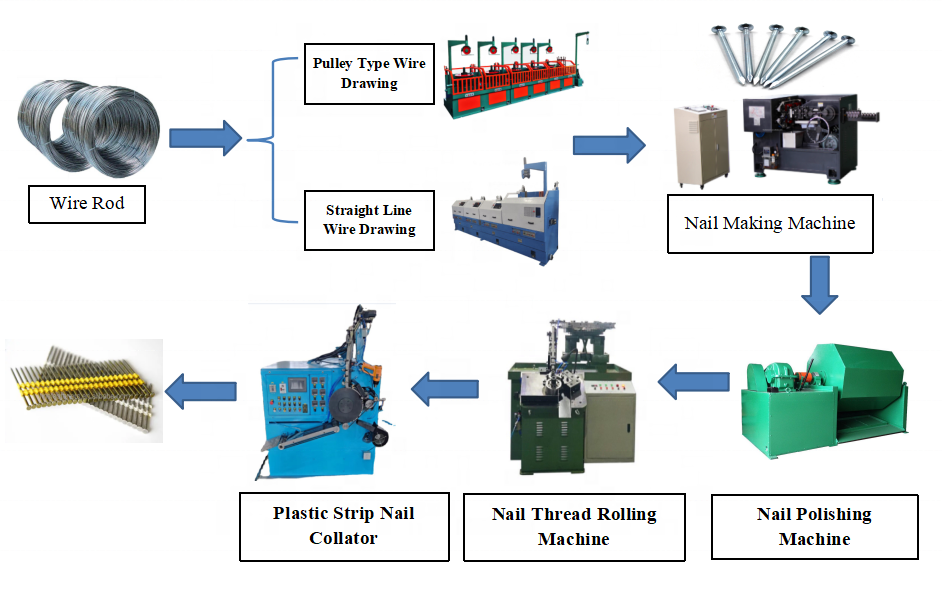

The FFI Plastic Strip Nail Production Line Stacking device with Robot Arm is definitely a product this is really made to affect a result of the creation of plastic strip nails easier and many other things efficient. The merchandise can be an investment that is great both little and business that is enormous trying to enhance their production line.

The FFI Plastic Strip Nail Production Line Stacking device with Robot Arm comes with a robot supply which has been programmed to pile plastic strip nails quickly and accurately. The robots supply works well at picking up an accumulation of fingernails through the production lines and putting them onto a pallets reason that are nicely accuracy that is enough.

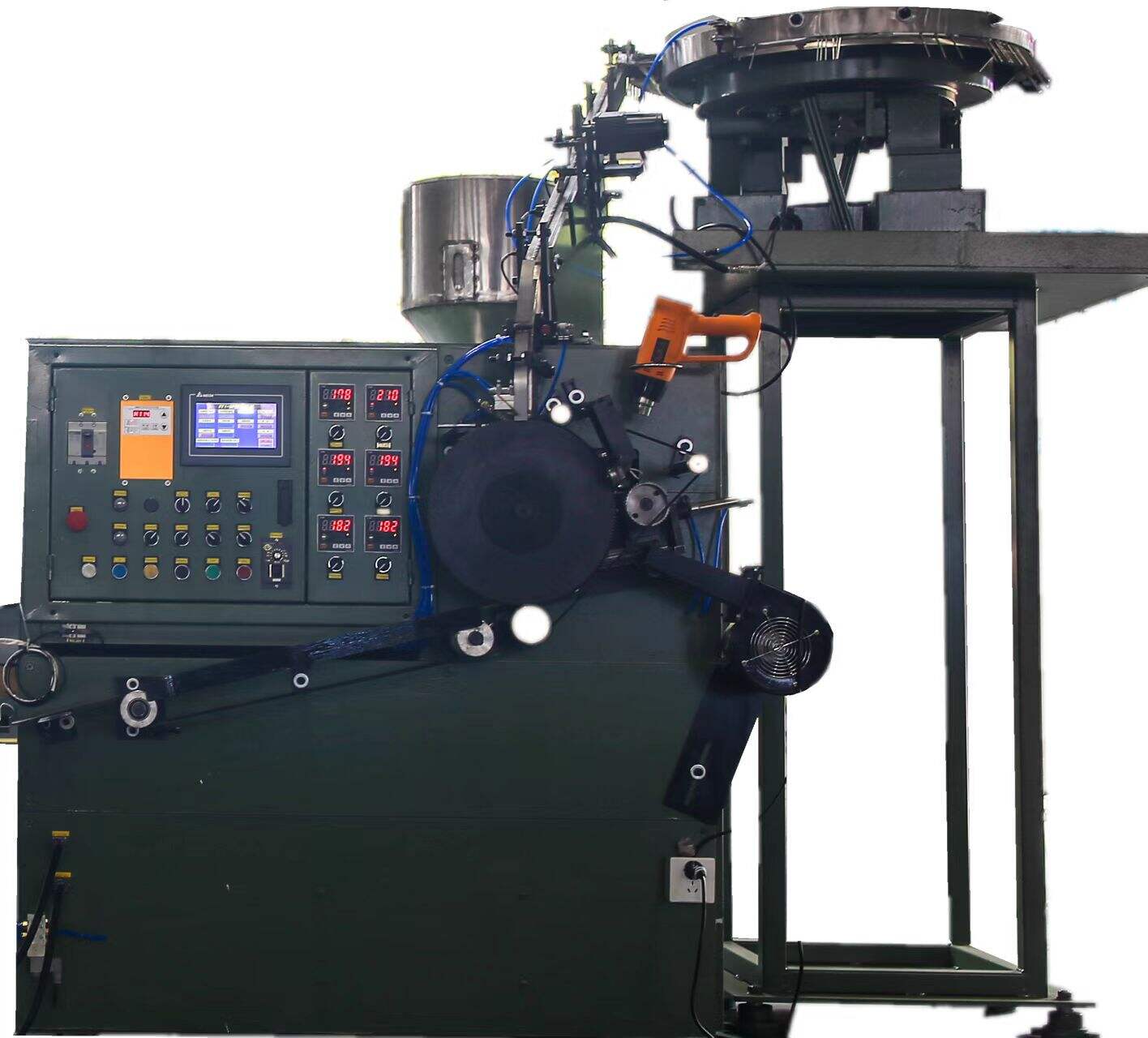

The merchandise was made to be user-friendly and just understandable. It boils down having a user that is graphical this is obviously easy-to-use enables the manufacturing line operators to control and monitor the stacking procedure. The customer interface includes a display this is programs that are undoubtedly user-friendly that is real-time the manufacturing procedures along with other essentials metrics.

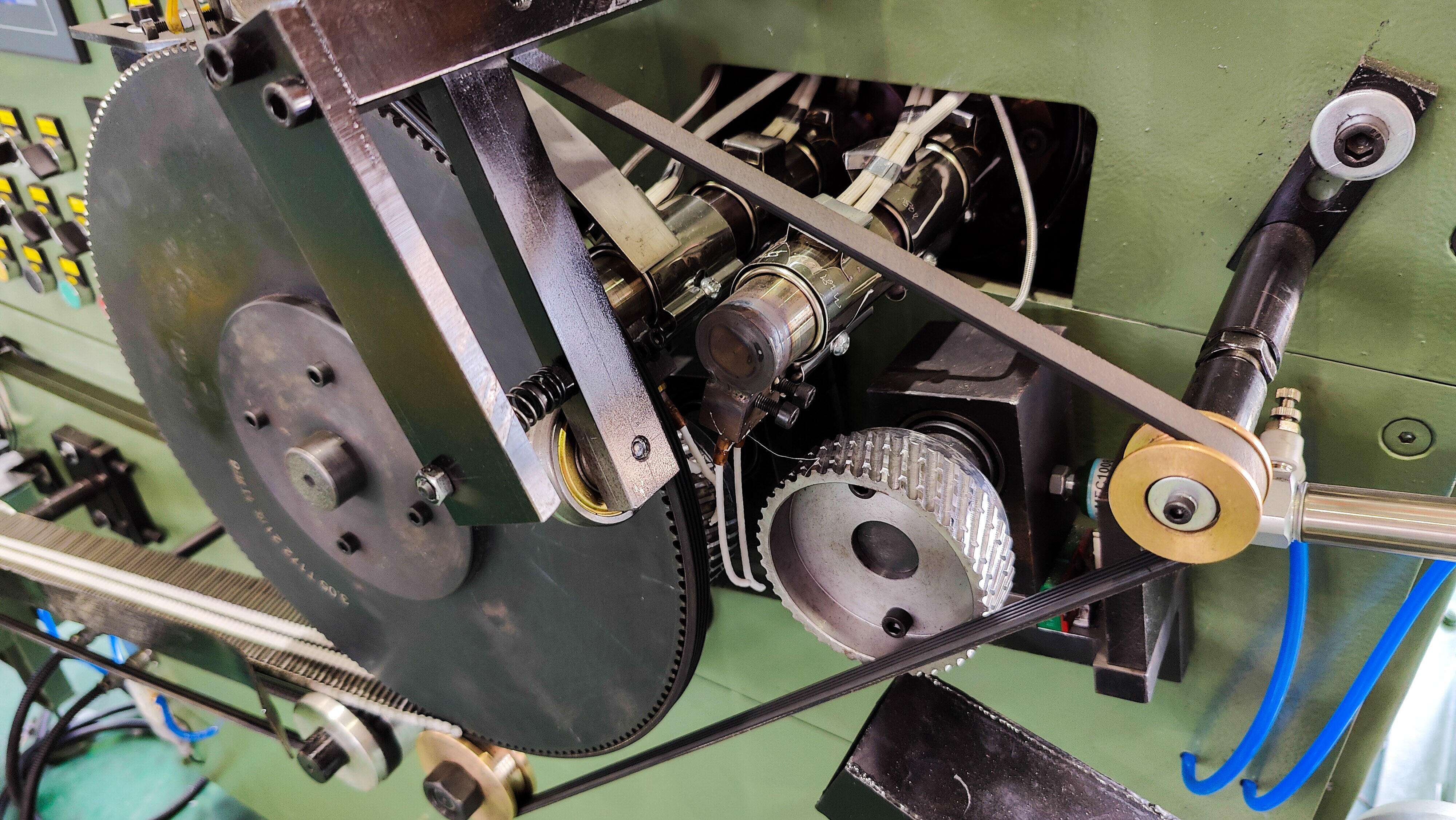

The FFI Plastic Strip Nail Production Line Stacking unit with Robot arm can be incredibly customizable. Possibly it is modified to finish business with many kinds sizes of synthetic strip fingernails, that causes it to be a device this is certainly versatile can charm to company that is various taype of work.

One of several major options that come with the FFI Plastic Strip Nail Production Line Stacking device with Robot Arm is its capability to enhance efficiency and effectiveness into the manufacturing line of the product. The product eliminates the necessity for human being intervention, thus reducing the possibility of human error and manufacturing that is increasing by automating the task of stacking plastic strip nails.

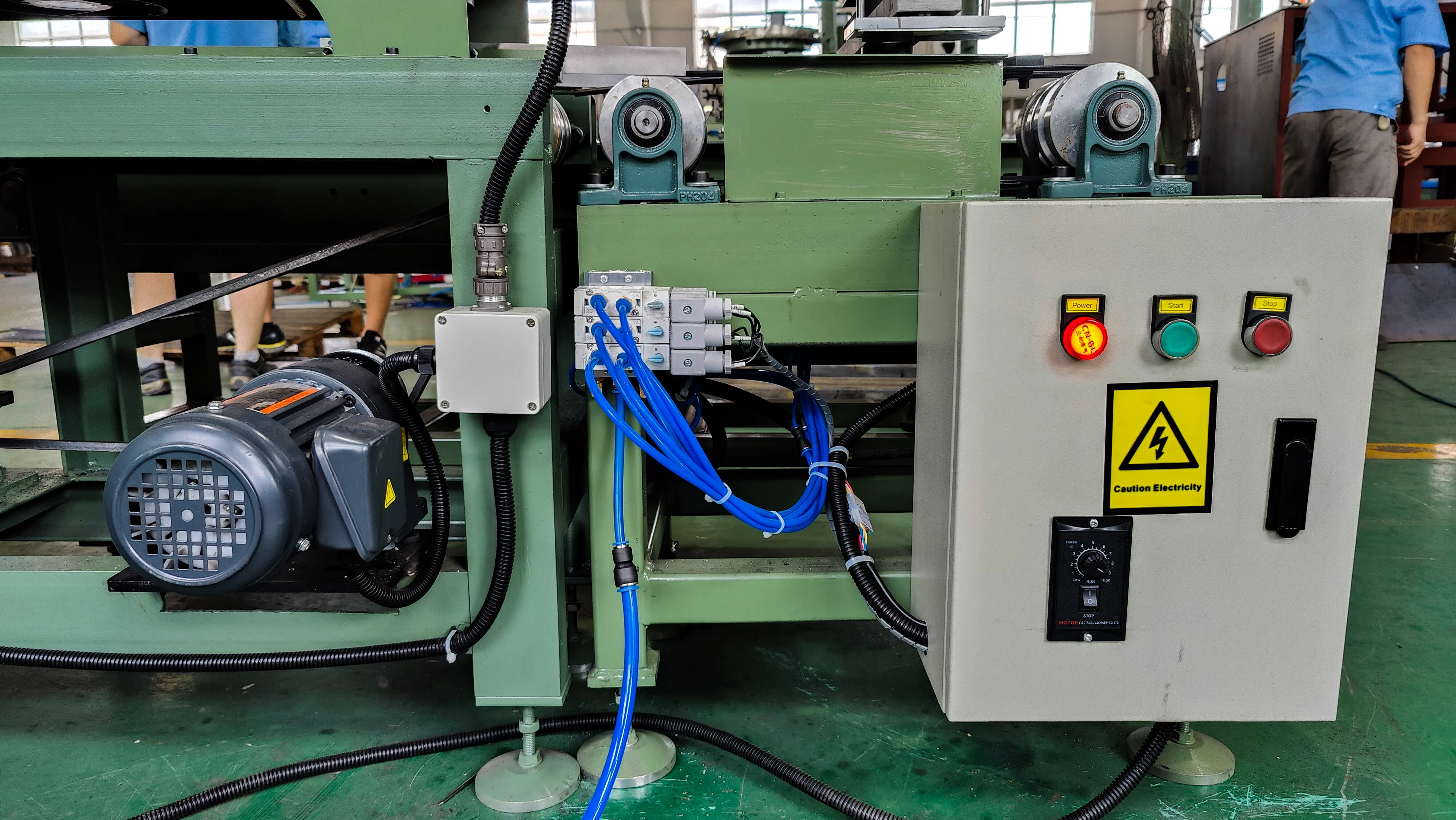

In addition, the FFI Plastic Strip Nail Production Line Stacking product with Robot Arm is incredibly dependable and safe to take advantage of. It was made to satisfy and exceed all quality and security requirements, making specific the productions operators being lined this product itself are protected on a regular basis.

Stay static in front side associated with game in the present market that is competitive.

Nail making speed |

1200pcs/min |

||||||

Length of nails |

50-100mm |

||||||

Diameter of nails |

2.5-4.0mm |

||||||

Angle of nail |

21 degrees |

||||||

Hot melting temperature |

0-400 degrees |

||||||

Air pressure |

5 kg per cm2

|

||||||

Voltage |

380v,50hz |

||||||

Machine Size |

L:2800MM*W:1800MM*H:2500MM |

||||||

Total weight: |

1600kg |

||||||

Plastic Position |

24-36/32-44 |

||||||

EN

EN