Product Description

The FFI Wire Production Line Mig Welding is the perfect solution for dependable, efficient, and welding that is top-quality. This product is built to allow you to create strong and welds which are accurate effort that is minimal maximum productivity. Whether you're welding structures that are large slim pipes, or anything in between, this machine will be the device that is much better for the job.

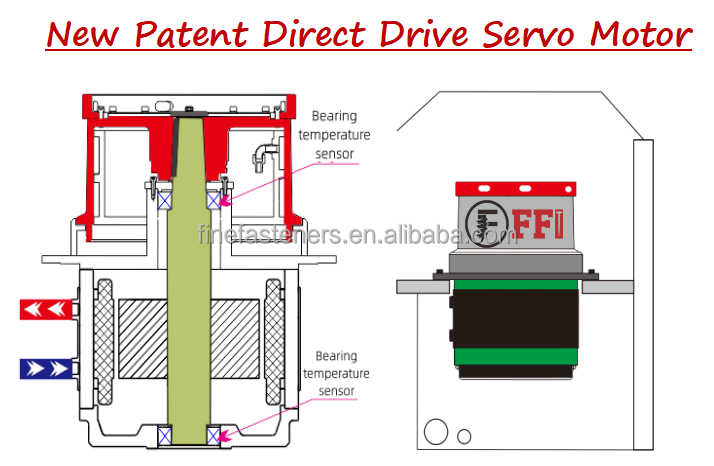

This Mig Welding machine comes with a control that is state-of-the-art that means you can easily set the cable rate and voltage to attain the weld this is certainly ideal. The FFI Wire Production Line Mig Welding normally intuitive and simple to work with, so welders which are even novice operate it with simplicity. These devices was created to deliver performance this is certainly excellent superior weld quality, rendering it an ideal choice for specialists and hobbyists alike.

The FFI Wire Production Line Mig Welding is built to your highest standards of craftsmanship and quality, making certain it'll continue for quite some right time for you to come. The frame in connection with machine is made of sturdy metal, which provides help that is complete the welding system. The device features a cable spool that makes it very easy to control and store the welding cable, plus the wire that is on-board ensures wire feed that is accurate.

The FFI Wire Production Line Mig Welding features a built-in gas regulator that helps ensure consistent and welding that is efficient. The equipment might work seamlessly by having a wide selection of metals, including aluminum, metal, and moderate metal, enabling you to manage virtually every welding task with simplicity.

The FFI Wire Production Line Mig Welding normally versatile for the reason why it might manage both slim and metals that are thick-gauge. This particular feature helps it be perfect for many applications, including fabrication, repair, and maintenance work.

I. Application range:

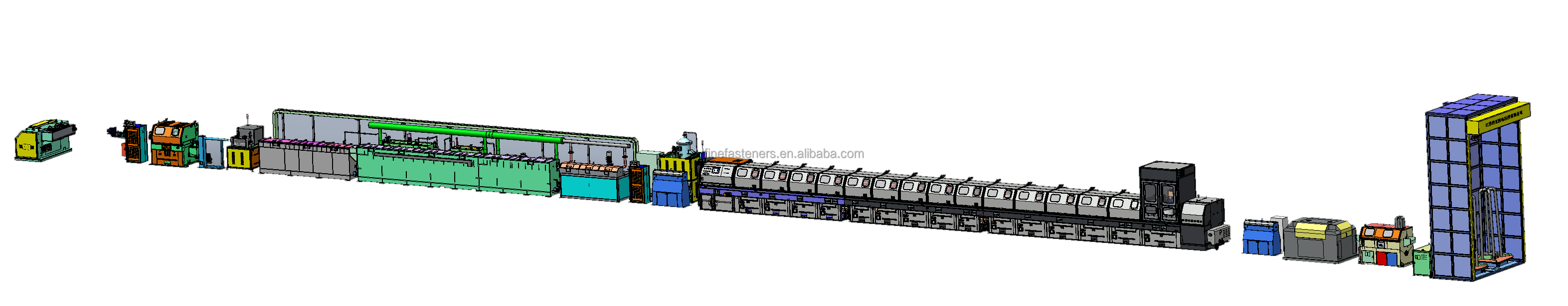

HD-20 welding wire production line is widely applied to manufacture MIG/CO2/SAW welding wires.

Welding wire type Wire diameter(mm) MIG/CO2 solid wire 0.8, 1.0,1.2,1.6 SAW solid wire 2.0, 2.5, 3.2, 4.0, 5.0

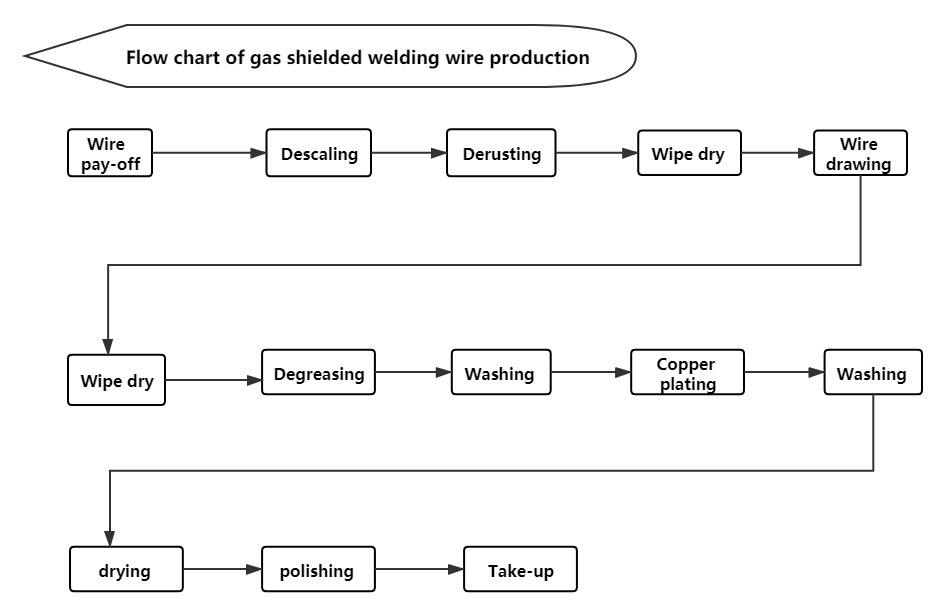

II. Process:

1. Wire rod pre-treatment line: remove the dirty from the wire surface

2. Wire drawing line: drawing the wire from large diameter to small diameter.

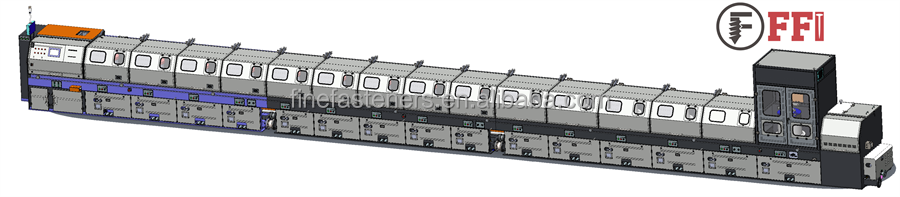

3. Copper coating line: Pay off machine+ constant tension adjusting+wire supporting wheel and wire turning wheel + big turning

device + mechanical degrease+ electrolytic acid pickling(rough cleaning )+electrolytic alkaline cleaning(fine cleaning)+ hot water

wash+ former neutralize+electrolytic acid pickling — cool water clean+ activate acid cleaning + chemical copper coating+ cool

water clean+Neutralized + hot water wash+ dry+ wire press fix wheel(roller) + big turning device + polishing drawing +take up

machine

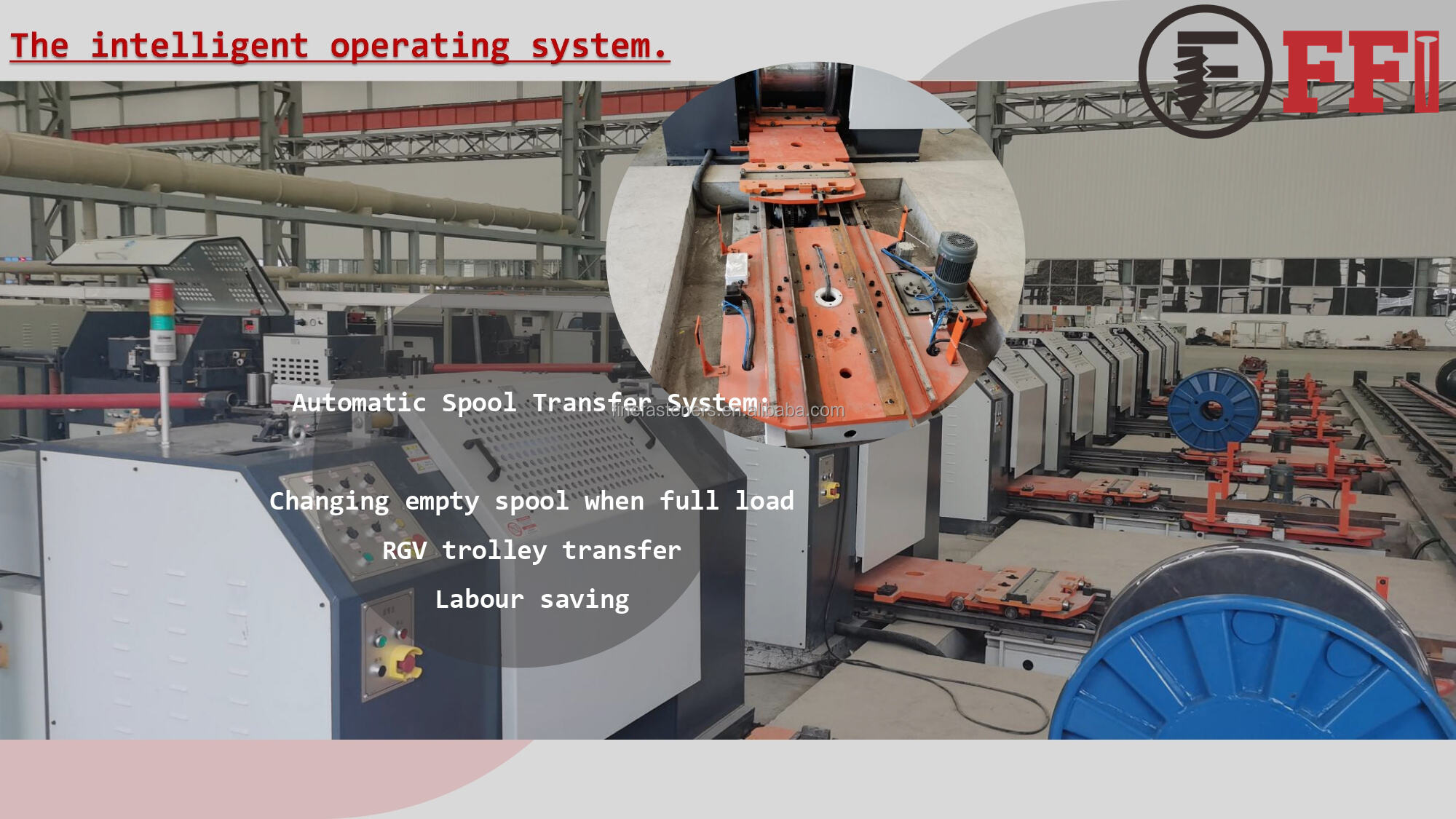

4. Laye winding machine: respooling the welding wire from the steel spool onto small plastic bobbin.

5. Drum packing machine: coiling the welding wire into a drum.

Product Name |

CO2 GAS MIG WELDING WIRE PRODUCTION LINE |

Wire Diameter |

6.5mm,5.5mm |

Brand Name |

FFI |

Year |

2022 |

Model Number |

FFI--XXCO2-6508B |

Dimension(L*W*H) |

21.5*1.450*1.6m |

Weight |

31280KG |

Place of Origin |

China |

Anhui |

|

Automatic Grade |

Semi-automatic |

Voltage |

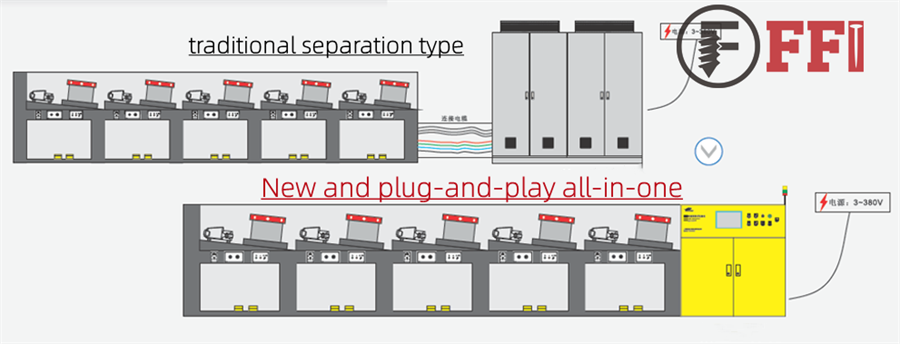

380V or Customize |

Power |

3000W |

Machinery Capacity |

Production capacity: 0.8mm--6.5t /1.0mm-10t/1.2mm-17t (20 working hours Max one day) |

Key Machines |

Metal Electroplating Machinery, Metal Polishing Machine, Metal Sheet Processing Machine, Lathe |

Product Type |

ER70S-6 Welding wire |

Finished Product |

15kg pallet weldingwire |

Usage |

Vehicles Bridge-engineering Machine-engineering Steel structures Ship manufacture Trade container |

Type |

Gas Shield Welding Wire |

After Warranty Service |

Online support, Field installation, commissioning and training |

Raw material |

Carbon Steel |

Capacity |

0.8mm--6.5t /1.0mm-10t/1.2mm-17t |

Feature |

Excellent Welding Performance |

Advantage |

Professional Manufacturer |

Certification |

SGS CE PATENT |

Color |

Customized Color |

EN

EN