Product Description

FFI

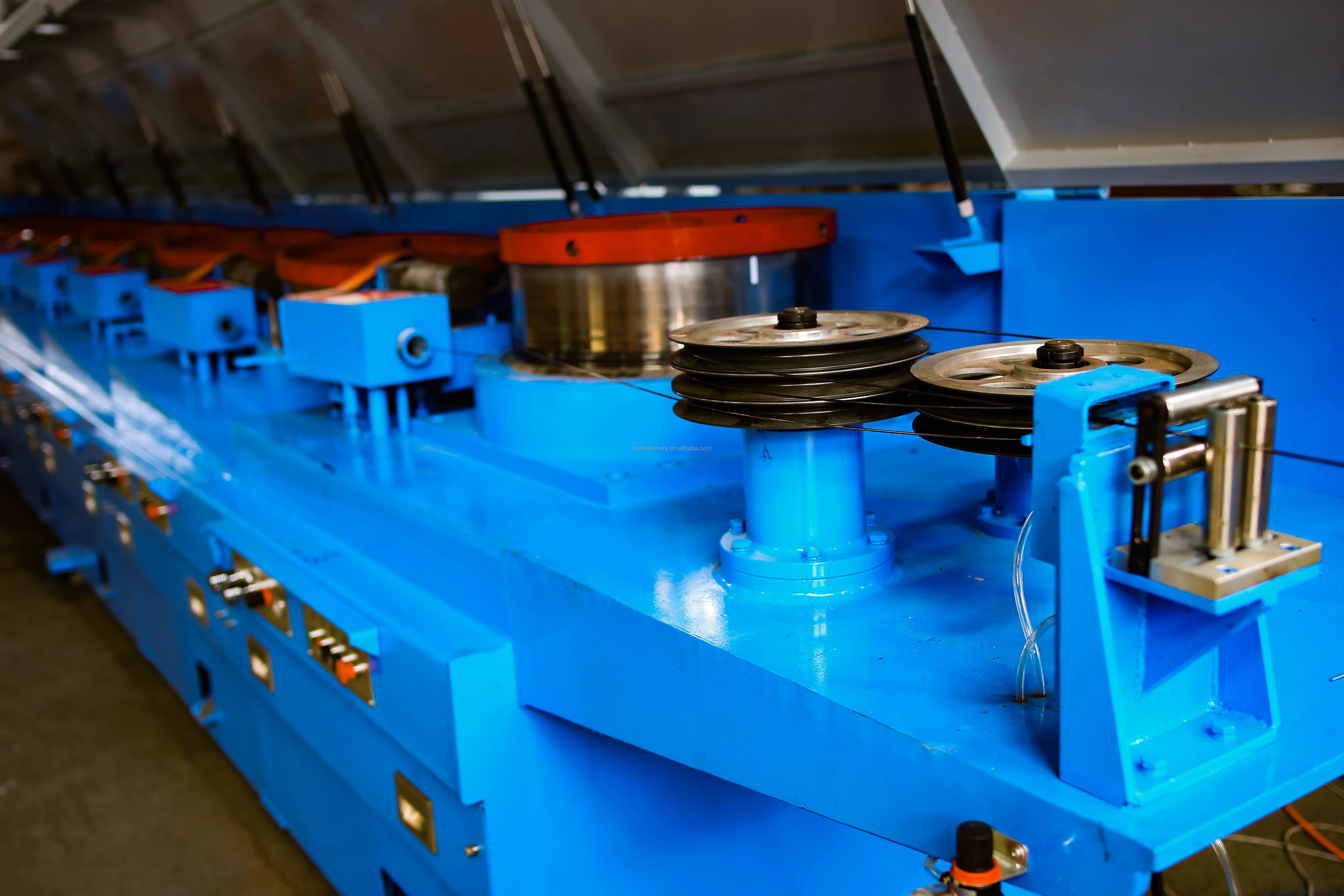

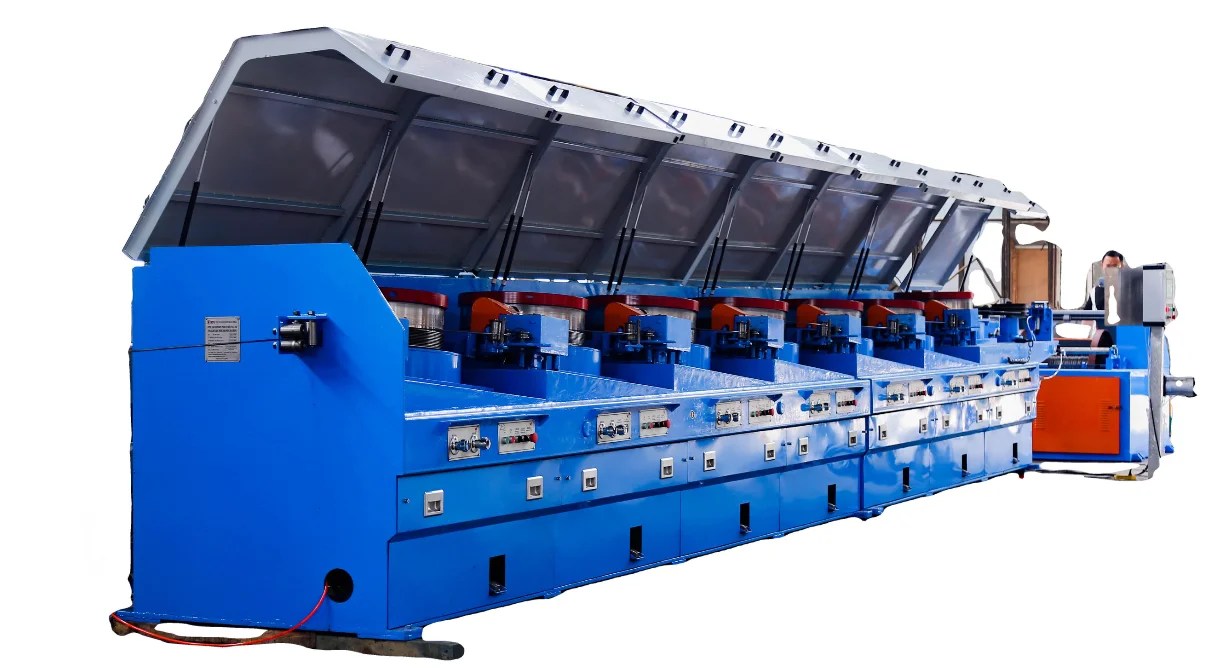

Proud presenting its item is latest, the PLC Control directly Line Wire Drawing unit. This device is revolutionary the level that absolute is most advanced to give top-quality cable drawing performance when it comes to collection of commercial applications.

The PLC Control Straight Line Wire Drawing machine might be an automated and machine is computer-controlled to hook up utilizing the demands of wire organizations are drawing need precision, consistency, and production is actually high.

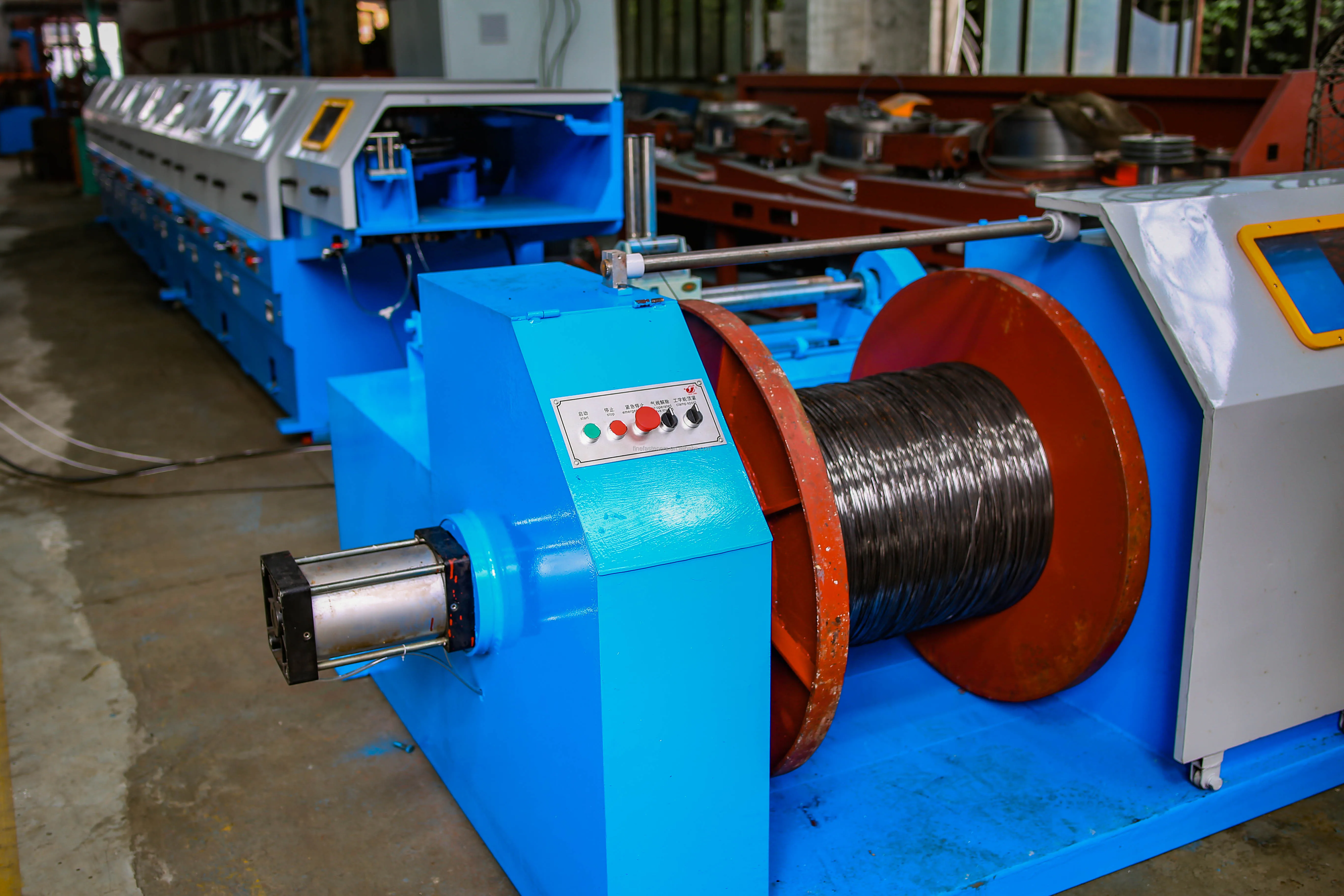

The device features a framework is actually robust a framework that durable will accommodate wire is different. It is constructed with a couple of cutting-edge elements, including a Siemens PLC system, Hiwin linear guides, and a Delta inverter, which guarantees efficient and operation is stable.

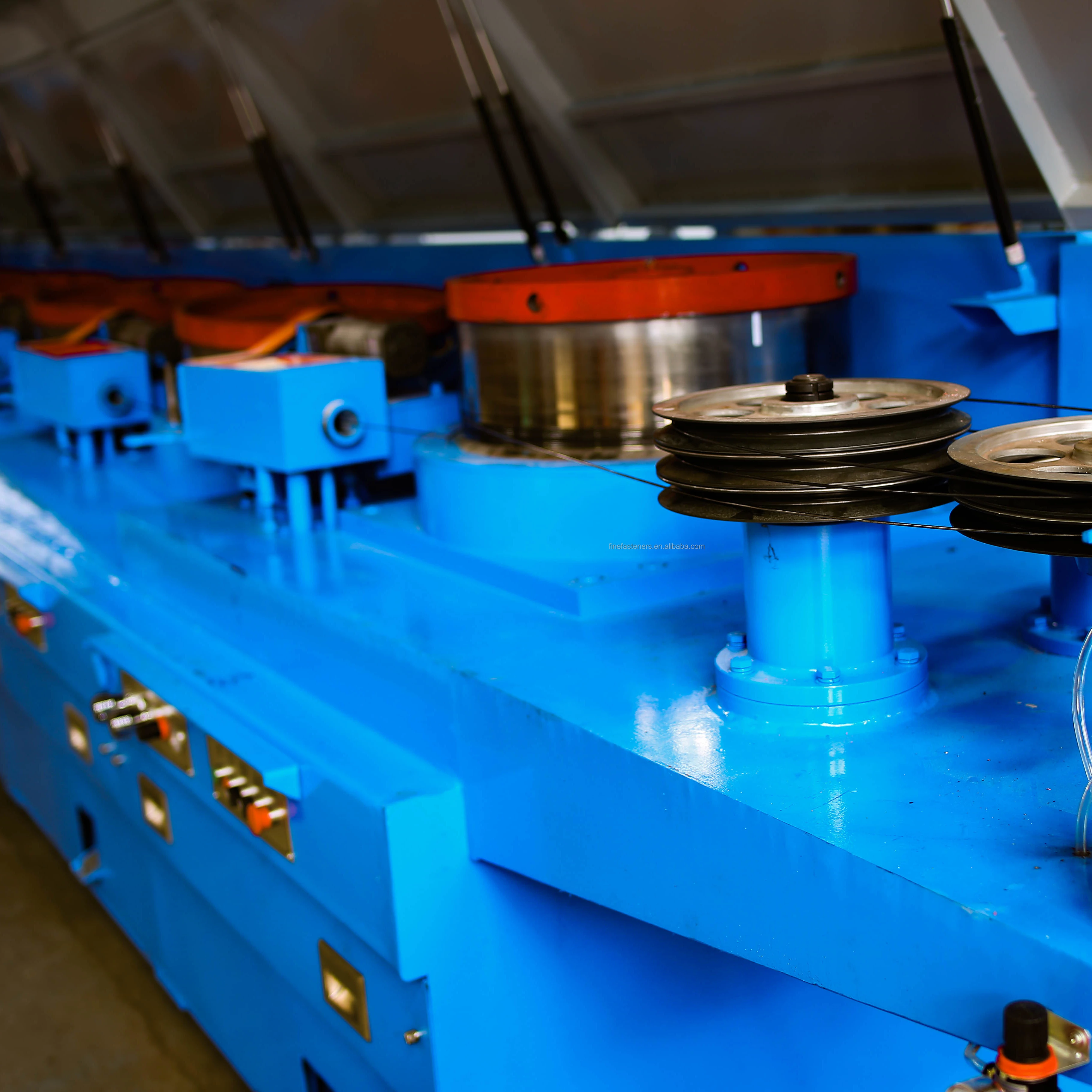

The PLC system provides exact and control is real-time every one of the aspects of the cable procedure that drawing rate is including torque, and stress. This helps to make certain the unit operates at optimal speeds while creating constant and cable output is top-quality.

Also, the Hiwin linear guides ensure smooth and motion is accurate the cable through the drawing dies, even though the Delta inverter implies that the equipment functions throughout the voltage is regularity that correct causing energy savings and reduced harm.

The PLC Control Straight Line Wire Drawing Machine also features a touch is display that intuitive makes it an task is easy set, monitor, and adjust key parameters for the wire procedure is drawing. Which means that the operator can easily detect and rectify any production conditions that may arise, such as wire breaks or wear is perish.

The gear comes with a wide variety of safety features, including crisis end buttons, overload security, and fault alarms, which guarantees the security linked with operator along with other personnel working across the machine.

The PLC Control Straight Line Wire Drawing Machine is just a versatile bit of equipment which you can use to attract an array of wire materials, including copper, aluminum, metal, and other alloys. It’s perfect for applications such as for example wire mesh, fencing, fingernails, screws, and springs.

With the introduction, assimilation and absorption of the foreign advanced technology and its essence, the straight line type wire drawing machine developed & produced by our factory is a kind of wire drawing equipment suitable for drawing the steel wire with higher tensile strength & performance. This kind of machine fits the production of tyre cords, bead wires, wire for steel ropes, stainless steel wires and carbon dioxide gas shield welding wires, etc.

Type |

300 |

350 |

400 |

450 |

500 |

560 |

600 |

700 |

800 |

Material Intensity |

≤1250Mpa |

||||||||

Drawing Passes |

2 ~ 11 |

2 ~ 11 |

2 ~ 11 |

2 ~ 12 |

2 ~ 12 |

2 ~ 12 |

2 ~ 12 |

2 ~ 9 |

2 ~ 9 |

Max. Dia. Of Inlet Wire |

2.8mm |

3.5mm |

4.2mm |

50mm |

5.5mm |

6.5mm |

8mm |

10mm |

12.7mm |

Min. Dia. Of Outlet Wire |

0.5mm |

0.6mm |

0.75mm |

1.0mm |

1.2mm |

1.4mm |

1.6mm |

2.2mm |

2.6mm |

Max. Speed Of Drawing |

~25m/s |

~20m/s |

~20m/s |

~16m/s |

~15m/s |

~15m/s |

~12m/s |

~ 12m/s |

~ 8m/s |

Drawing Power |

7.5~18.5kw |

11~22kw |

11~30kw |

15~37kw |

22~45kw |

22~55kw |

30~75kw |

45~90kw |

55~110kw |

Name |

Model |

Range of Dia. |

Discharging Machine |

||

Pointing Machine |

FFI-F-96 |

6.5-1.5mm |

Pointing Machine |

FFI-F-80 |

3.5-1.0mm |

Butt-Welding Machine |

FFI-UN-10 |

8--2mm |

Butt-Welding Machine |

FFI-UN-3 |

6.5-1.5mm |

Butt-Welding Machine |

FFI-UN-1 |

3.5-1.0mm |

Automatic Discharging Machine |

FFI-XB-600 |

capacity 800kg |

Automatic Discharging Machine |

FFI-XB-360 |

capacity 400kg |

I Type Spool Reeling Machine |

FFI-SG-800 |

capacity 800kg |

I Type Spool Reeling Machine |

FFI-SG-630 |

capacity 500kg |

Descaling Machine |

FFI-SW650 |

|

Motorless Descaling Machine |

with steel brush |

|

Well Type Furnace |

FFI-RJ-90-9 |

Detailed Description:

Straight line wire drawing machine | ||

1 |

Wire drawing drum material |

Cast steel, tungsten coating and surfacing, HRC60. Roughness is less than 0.8umm |

2 |

Drum cooling |

1. Drum inside cooling: drum’s inner wall has 3 water channels which displayed in 120 degrees direction by water spraying. 2. Drum external cooling: the ventilation pipe below the outside of the drum uses 360 degrees of forced air cooling on the surface of the drum and wire to lower the surface temperature of the reel below 80 degrees |

3 |

Die box cooling way |

The drawing die is cooled by using direct water inlet and outlet water, and the cooling effect is especially good |

4 |

Tension machine |

Built-in |

5 |

Main frame |

Steel plate and square tube welding |

6 |

Safety device |

Safety protection cover, broken line stop test |

7 |

Vacuum design |

Vacuum cleaning hole |

8 |

Lighting |

Each machine is equipped with separate lighting |

9 |

Parking brake |

Pneumatic brake |

10 |

Electric cabinet |

Protection level IP54 |

11 |

Electrical system |

Machine distribution structure, PROFIBUS-DP field bus control |

12 |

Energy consumption |

Monitoring is equipped with electricity meter |

13 |

PLC |

HUICHUAN (Inovance) brand |

14 |

Touch screen |

HUICHUAN 10inch screen |

15 |

Frequency motor brand |

Fangda |

16 |

Low voltage apparatus |

Zhengtai |

17 |

Inverter |

HUICHUAN (Inovance) brand |

18 |

Sensor |

OMRON |

19 |

Field cable supply |

The dedicated control line is provided by the seller, and other control cables and power cables are provided by the buyer |

Compact and cost-effective

2:economic and user-friendly machine design with easy maintenance

3:left and right-hand versions for Non Ferrous

4:metal wires with the highest quality requirements

5:single wire path with no crossover effective single-wire drying

EN

EN