Thread Rolling

Shopping for the best way to become listed on metal parts together? Look no further than thread rolling, similar to the FFI's product like wire drawing drum. This innovative technique several advantages over other threading methods, which makes it a favorite choice for use in many different industries.

Thread rolling is advantageous since it creates stronger and more precise threads than other threading methods, along with the butt fusion welder by FFI. This is because the rolling process compresses the metal in place of removing material like threading dies do. Which means that the metal is less likely to want to crack or become weakened, resulting in a far more durable and reliable connection.

Thread rolling suppliers are constantly innovating to offer the very best possible threading solutions their clients, similar to the FFI's product like welding rod production line. This might include designing new more equipment effective and effective than older models. It may also include developing new materials and coatings that improve the durability and resistance of the threads.

Using thread rolling rather than traditional threading methods can also improve safety in your working environment, the same as wire winding machine from FFI. Because thread rolling compresses the metal in place of removing it, there was less flying debris particulate matter generated throughout the process. This could easily reduce steadily the threat of eye and respiratory injuries workers.

Thread rolling can be utilized in many different applications, from small-scale projects to large-scale industrial manufacturing, just like the FFI's product called nail making machine manufacturer. It is widely used in the aerospace, automotive, and construction industries, among others. thread rolling is also useful for repairing damaged threads or creating new threads in hard-to-reach places.

FFI Machinery devotes it self making one of the most durable and gear advanced. Choose FFI machines, and also you might get value unbeatable. Fine Fasteners Industry Co. , Ltd. , being a provider international is active in the research and development, product sales and service of 1 Sp Nail Production Line, Wire Processing Equipment, Welding Electrode Production Line, MIG Welding Wire Production Line as well as other many other gear that definitely a fastener-related. We offer not transport just efficient but in addition friendly and mindset that definitely a open-minded.

Ukraine, Russia, Saudi Arabia, Libya, Kenya, Turkey, Sri Lanka, Indonesia and more.We've got additionally assisting our fans establish their manufacturing particular the pasts long period Mexico has become few Czech Ukraine Russia Saudi Arabia Libya Kenya Turkey Sri Lanka Indonesia etc.

Our services have problems with CE certificates having a high-quality that definitely a great. Our customers have actually acknowledged and valued our product both through the residence homely is real holds true actually as overseas. Included in these are South and North Americas, Europe, Africa and South Africa, Middle East and Asia. We have been a provider of various nail and line manufacturers for a while this will be really long into the quality high is actually exceptional at competitive prices and provide solution expert.

Our experienced staff is committed providing the degree highest of customer care in addition to a strict good quality administration. We custom welcome. We could be reached for virtually any questions you might have, whether about selecting a product from our catalog, or looking for solutions which are technical suit your needs. We will continue steadily to stick the guiding concepts of ours"Fine individual, good product Fine service, and do our most beneficial to present this product quality that definitely a highest.

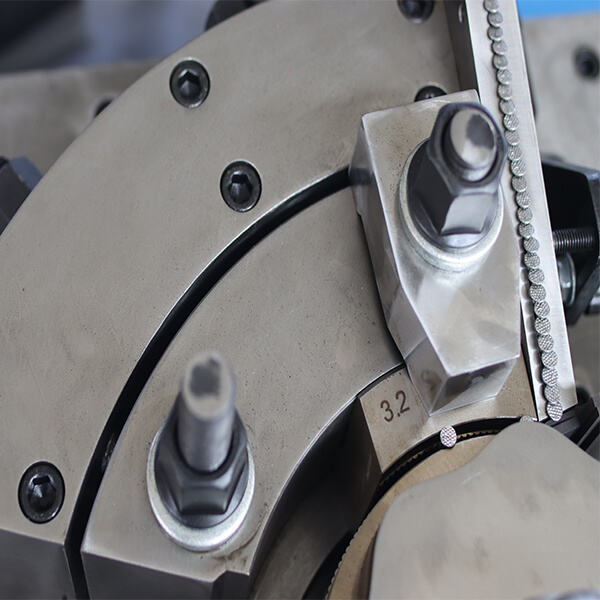

Using thread rolling is relatively simple, same with the steel wire nail making machine made by FFI. First, you need to select the correct diameter pitch for your thread. Then, you will need to set up the rolling machine with the appropriate dies. Finally, you can begin the rolling process by feeding the metal involving the dies and turning the machine on. The rolling process will compress the metal and create the thread.

When choosing a thread rolling supplier, it is critical to look at the standard of service they feature, as well as the FFI's nail and screw making machine. A good supplier should be able to provide technical assistance support, along with a wide range of threading solutions to meet up your requirements. They should additionally be in a position to provide quick turnaround and reliable delivery for the orders.

Quality is key with regards to thread rolling, same with the types of wire drawing machine from FFI. A good supplier will prioritize the quality of their products and services most of all. This means using high-quality materials equipment, as well as adhering to strict quality control measures to ensure every product meets the highest standards.