Introductio ad processum productionis fili sutorii Unus locus fabricationis fili sutorii est linea productiva unica; fili expliciti sunt inventi tantum causa suturae. Sutura est methodus coniunctionis materialium, solito quod finguntur metalla aut thermoplastica. In hoc articulo, vobis narrabimus plura de eo quid sit filum sutorium et quomodo fiat. Et etiam cur accurate qualitas horum productorum inspicienda sit. Disputabimus etiam conceptus qui mutaverunt industriam et quemadmodum optimizare possimus stadium productionis minore costa.

Processus fabricandi filum Alia Basis filum utitur ad conficiendum Filum Impletorium Suturarum et initium habet a materia prima. Fili: FFI Ferrum clavium faciens machina fili formantur ex genere variorum generum materiarum, quas utuntur. Metalla maxime utilia in hoc processo sunt ferrum, aes et Zinthus. Ex his, materia ad conficiendum filum soudandum ferri est maxime curae. Ferrum primum calefit donec in liquidum solvitur. Liquidi ferri deinde inducitur in magnam lacunam. Hoc vas format ferrum in virgam fili, quod est prolongata pars metalli.

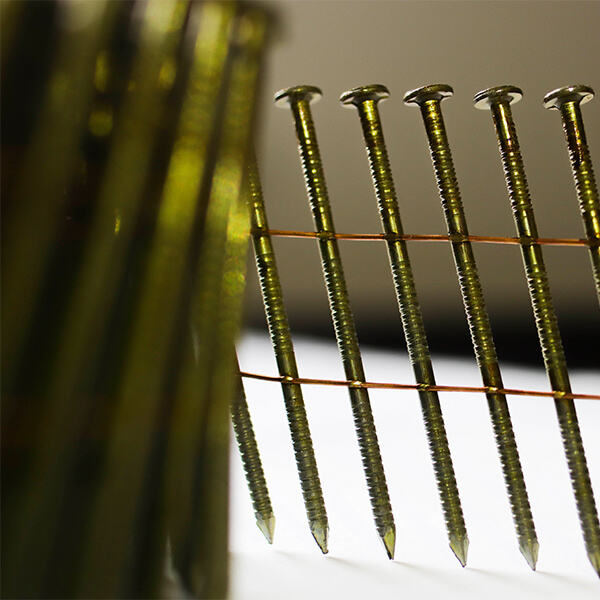

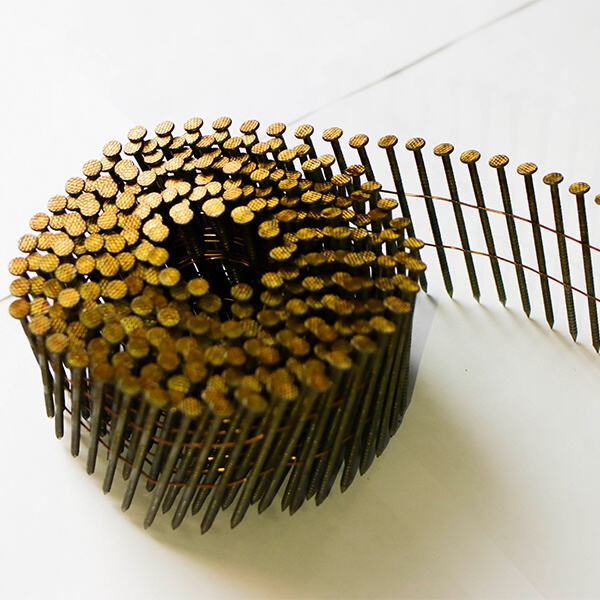

Procedo sequens postquam filum virgultum creatum est, tractatio fili. Matrices sunt instrumentum speciale per quod trahitur virgultum: vocatur Tractatio. Filius traicitur per matrices quae gradatim reducunt eum ad magnitudinem necessariam pro sutura. Cum filum ad diametrum finalem ductum est, purgatur ut terra et immunditia amoveantur. Purgatum cum tenui strato cupri vel zincum super filum. Primum est tegumentum super eum - hoc valde importante est pro conservatione fili, sicut etiam iuvat moram sui processus ferruginationis et durare diutius.

Qualitas FFI Filum cuprinitum ferri etiam potest examinari secundum vim suam tractionem. Hoc appellatur vis tractionis. Parametrus criticius in pompa tua caloris est eius vis tractionis seu quantum vis filum sustinere potest antequam frangatur. Filius probabiliter cito frangetur durante sutura, reddendo ipsum inutile ad usum in opere. Hoc est ratio cur fabricatores fili tam diligenter probant pro fortitudine.

Memento, altera probatio critica qualitatis est mensura fili argentei tui. In hoc casu, filum aut nimis parvum aut magnum est et non operabitur in machina soudanti. Hoc, vicissim, causat problemata cum coniunctionibus infirmis et norma laboris non ad par esse. Quid hoc FFI Pretium machinae conficiendae clavorum ferreorum facit ut filum recte operetur et poterit bene superare expectationes pro eo quod clientela eius eam indiget.

Automatisatio est una ex modis quibus meliorem facere licet processum. Ut antea dixi, robotess utiliores possunt fieri ad volumen fili conficiendi augens quod vicissim exitum levabit. Id fieri potest per minuentes errores qui ultra meliorem facient processum. Maior qualitas controllo etiam deprehendit problemata ulterius in linea ante quam ad hanc stadium perveniunt. Negotium citius est, suggerre offendo supportem et minus materialem tempus perdere possumus.

Parcimonia in denariis etiam per conquirendum ingredientia rudimenta viliora consequi potest. Hoc significat altercandam cum praestantibus mercatoribus pro meliore praeio, vel circumferendo ut novos invenias qui viliora praebere possint. Fabricatores qui possunt sumptus regere et aliquot puncta percentuales a structura sumptuum abscidere, habent facultatem diutius negotium gerere, vendere si volunt aut summam pecuniam ab investitoribus accipere in omnibus stadiis productionis.

FFI Machina se dedicat suppeditare recentissima et perpetua instrumenta. Eligere FFI apparatus, et forsitan pretium incomparabile consequeris. Fine Fasteners commercium Co. , Ltd. , peritus suppetitor qui vere orbem terrarum coniungit cum investigatione et promotione, simul cum acquisitione et conservatione 1 Sp Clavus Productio Linea, Filum Processus Apparatus, Coniunctio Electrode Productio Linea, MIG Coniunctio Filum Productio Linea aliaque apparatus coniuncta cum firmamentis. Nostri non solum scientiam praebemus sed etiam strategiam efficacem coniunctam cum apparatu necessario.

Servitia et producta nostra vere acceperunt certificata CE societates bonitatem quam plane magnam. Consumatores nostri verum agnoverunt et aestimarunt servitia nostra tam in America quam ultra mare. Includentes Americam Meridionalem et Borealem, Europam, Africam et Africam Meridionalem, Orientem Medium et Asiam. Fuerimus pars fabrorum clavorum et tectorum per tempus quod vere longum est, praebentes optima qualitate ad pretia nimis parva. Praestamus etiam servitia perita.

Negotium intendit circa exercitationes ministerii et in technologias quae potuerunt meliorem productivitatem et qualitatem optimam praebere. In nostris conatibus, item iuvamus clientes nostros stabilire particularia productionis suae tempus est proprium suum ante dies.

Ad quaestionem rigorosi controlis qualitatis et clientium attenti, noster peritus ministerium saepe servabit diligenter lineam interactionis apertam ad nos dedicatos consumptores. Velimus vere audire de operibus consuetis. Sumus nobis si cogitas aliquid ex nostro catalogo, vel si quaeris solutiones technicas quae satisfaciant desideriis tuis. Continuabimus conformes principiis nostris: homo bonus re bona bonum servitium et faciemus ut suppeditemus optimum qualitatem maximam.