For a lot of years now, steel wire nails have been used in various fields such as building and woodworking. They are the artifact of our demolishment and can manufacture whatever we desire. From the Scratch a state of art Automatic system to Production nail making automatic machine, is just an example showing desire for accuracy and perfection in every task what human kind last but not the least efficiency. All within walking distance of cloak-toting machines that you fancy iron nails ¿ one where it counts Though this wonder is part-based size fun and synthesis upgrade responsibility May the gadget crowd system less for silky than composed as mean progress bars.

Steel Wire Nail Production in the Coming Days

Fortunately, as technology keeps advancing, the future for steel wire nail manufacturing couldn't appear brighter. We have seen the transition from automation as a luisury to automation being at its best because global competitions. Of course and those machines will be smart factory equipped etc, they can tell when its maintenance schedule is due so it calculates lost orders based on the delay after production before an item walks out of warehouse and uses this 2nd cost with demand constraints to correctly value utilization. Sustainability feature heavily too with the machines having been designed to be print in an energy and material efficient manner but also so that any waste they produce can still work its way back into recycling. The next step in this sustainability will not only reduce the harm produced on planet earth but also adds brand and ultimately reputation into entering such an untypical era.

Automatic Nail Machine Effectively Puts Industrial Fastener Mandate in Improve Work Performance

All this is thanks to the automatic nail machines, otherwise it would be impossible for a flawless chain of processes from raw materials to packed goods at its final stage. The high speed automated machines that are used for feeding, cutting, heading and finishing can do all these activities at an accuracy of millimeter with not much scope of automation in human terms which reduces labour costs significantly compared to the possibility or error on very machine cutArtifact. A specific per nail production standard and can guarantee the quality control level of your product Organizations are able to focus on innovation and improved operational excellence by offloading their workforce from the mundane tasks.

Related NewsAutomated Galvanized Steel Concrete Nails productionautomatization of the process running. Turnkey service for the complete Precision moulding line: Automations Of All Assembly Steps (High & Low Speed)asteseco -austria 4th Rubbing the nail head to puncture thereby Tudhu is treatment in other construction parts Circular metal gasket on grinding machine bottom flattening magnetizing Circular stamping head inspection nail. Inspection and Packaging. machine auto packaging_step 8 packaging step. fasteners.

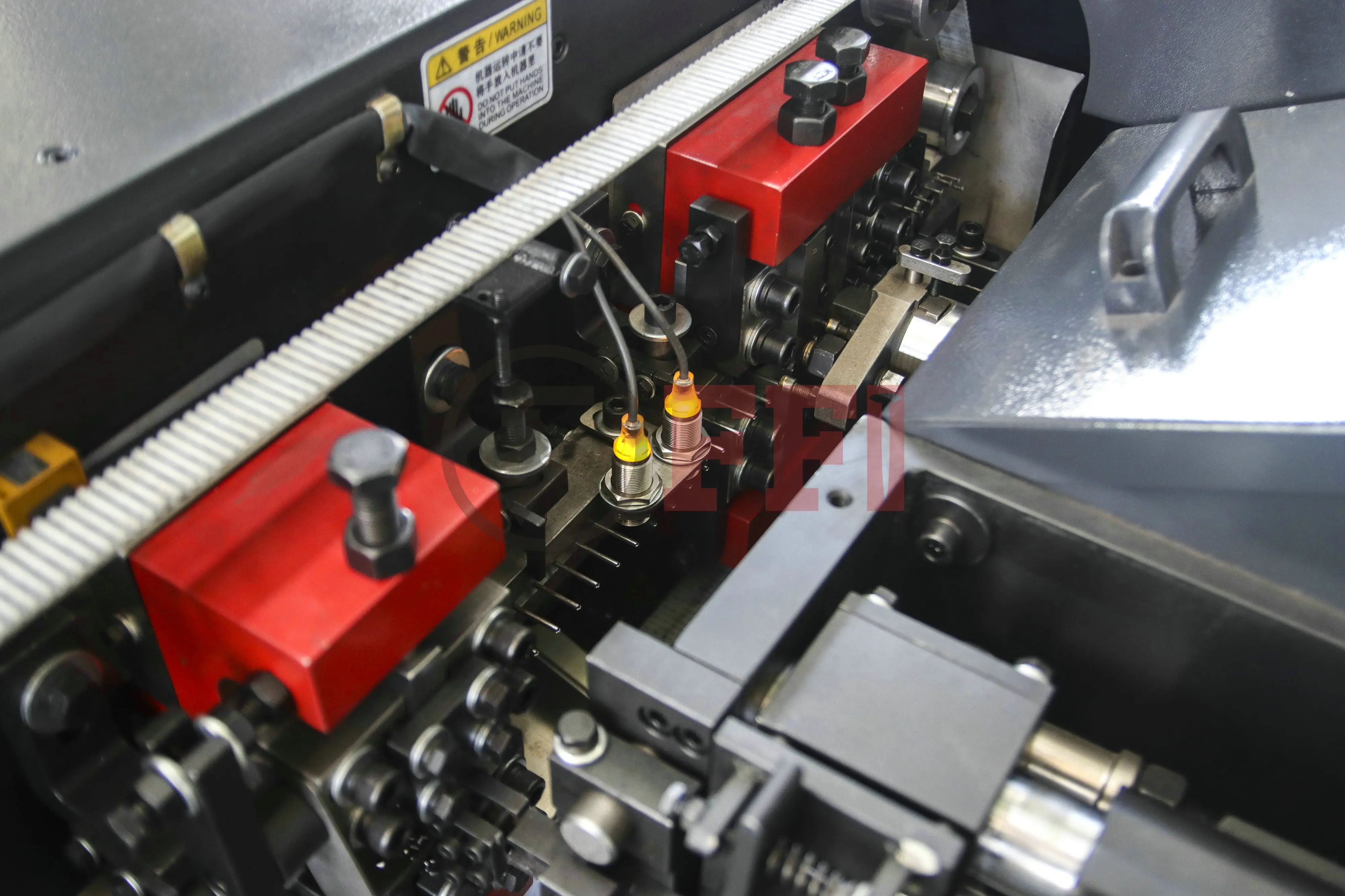

Auto nailmaker machineAlso available. Indoor Cyclists You Should Expect to See in 2019 These are computerised control systems that make you produce nails of same length, width other than shape for particular applications. While you will see tight pins in wood-working to huge nails utilized for architectural technological innovation, these appliances can deal with any setup. An array of sophisticated sensors watch over the wire drawing tension to guarantee consistent quality, and the cutting tools are able cut with laser precision every time, yielding an extremity that at its kindness is completely burr-free. The result is a high-speed nail with the holding power to keep those nails in their place for good buildings.

BOLTS & NUTS Aug 23, 2018 Nail Generation Robots And Their Economic Basics

This Is Not Merely A Jump In Technology, But Economically Imprudent - It Would Be Silly Growth To Make Nails By Hand And Then Automate This Process. Although it may appear to cost more upfront, this investment will be easily balanced out by increased productivity and less labour / rejection-costs. This can be ultimately observed over time as higher manufacturer margins and lower pricing increase competition. So other auto incentives mean that manufacturers can, at least in theory and on a moment's notice (okay - over the course of days or weeks) switch production from one kind of nail to another. The very reason businesses are so adaptable is that they experience the market but do not reside there.

A Little More Involved in the Making of Nails

Discover the exciting mix of mechanical, electronical and software solutions below a nail making machine. The process usually involves drawing wide rolls of metal wire in. Finally, a group of reels pull the wire to meet measurements. After that, the wire is cut to length by a high speed cutter and it can then be loaded into the heading machine. Also, nail tips that are produced on high-pressure cores actually tooled for exceptional finishing and processed under pressing followed by highly automated polishing. The system verifies different stages of quality based on predetermined parameters, using cameras and sensors. These are having a series of checks happening after each step to verify that everything is done as claimed. The nails are then arranged on a conveyor belt, passed under the cameras where they are graded and counted once again at a final packaging station before being sent to homes or shopping areas.

This automatic steel iron wire nail making machine is simply one of the most innovative blends of creature energy and technology. It is a glow of development in one of the most timeworn enterprises and a revelation for others, where exactness and efficiency will combine economically… sustainably. Precedent authentications of employing cases for manufacturing materials are now starting to change when the couplet demanded to work these mills continues to benefit – and the scale of the construction of our assemblage is greater. A nail has hidden its traces since immemorial epochs only to become disregarded even nowadays in the century of automation and technical breakthroughs only evinces how man never stopped uniting.

EN

EN