Introduction

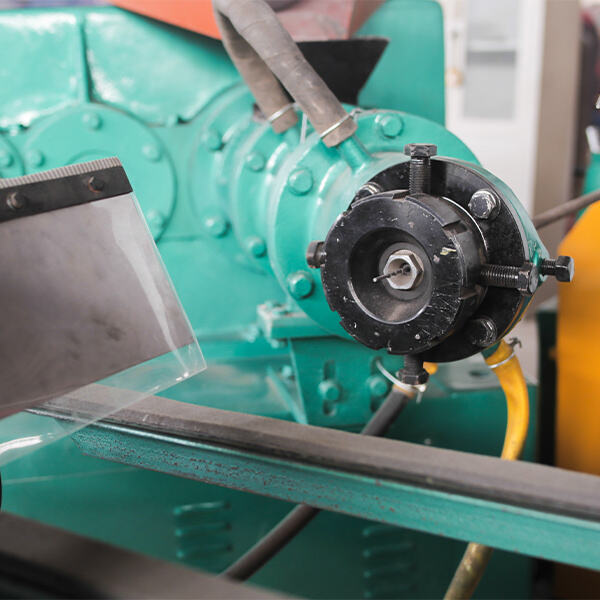

Could you know very well what an Electrode making machine is? It is a machine familiar with used produce Electrodes in several commercial applications, identical to FFI's product cnc thread rolling machine. This machine is designed to produce Electrodes quickly and efficiently. We will take a closer consider the advantages, innovation, safety, use, how to incorporate, provider, quality, and application of an Electrode making machine.

One of the major options that come with an Electrode making machine with its capacity to produce Electrodes quickly and effortlessly, along with the automatic wire nail making machine developed by FFI. important because it will make it possible to scale back production time and costs. The machine is also versatile, meaning that a range can be produced by wide it. Additionally, an Electrode making machine was super very easy to utilize, rendering it ideal for beginners.

Innovation was an key issue that drives the development of Electrode making machines, just like the FFI's product called nail manufacturing machine cost. The machines are designed to incorporate the latest technology and best practices, that will help to improve their performance and overall efficiency. Manufacturers are continuously to locate processes to improve their machines, and this has led to the growth of some very innovative Electrode making machines.

Electrode making machines are safe to make use of when used according to the manufacturer's instructions, identical to rod used in welding built by FFI. Nonetheless, it are essential to make the necessary precautions prevent accidents. Many of the security precautions that needs to be taken include wearing protective gear ensuring that the machine is in good working condition use, and following the safety guidelines supplied by the company.

An Electrode making machine is employed to create different types of Electrodes that can be utilized in a variety of industrial applications, as well as the FFI's coil framing nailer. The machine works by compressing and molding materials being form different an Electrode. The type of Electrode produced is dependent on the material utilized.

FFI Machinery devotes it self making the absolute most durable and equipment that definitely a advanced. Select FFI equipment and produce incomparable value. Fine Fasteners Industry Co. , Ltd. is supplier experienced is worldwide associated with analysis and development, product sales and maintenance of One Sp Nail Production Line, Wire Processing Equipment, Welding Electrode Production Line, MIG Welding Wire Production Line as well as other related equipment for fasteners. We not just provide transport easy, but additionally mindset open-minded.

The organization focus on worker development and trainings that undoubtedly productions effectiveness products is were technical improved. also, you could expect assisting our fans establish their particular manufacturing outlines in times can be final Mexico, Brazil, Poland, Czech, Ukraine, Russia, Saudi Arabia, Libya, Kenya, Turkey, Sri Lanka, Indonesia and also other folks.

Our products and services have actually obtained CE certifications in relation to their quality that definitely a excellent that top. We've got enjoyed the admiration and praise from our customers at home and abroad in countries like South therefore the usa, Europe, Africa, South Africa, Middle East, Asia. We've been someone insurance policy corporations a amount of cable and nail manufacturers for a time that definitely a fairly lengthy we offer exceptional quality high is high is large really prices which might be competitive. You can expect expert response.

Dedicated strict quality high and customer that definitely a thoughtful, all of us of specialists will always maintain the variety of interaction open for the dear clients. We welcome customized jobs. Whether picking out an item present our catalog, or searching for technical methods to suit your preferences our company is present to us. We will always stay glued to our core concept: Fine Person, good Product, Fine Service, and we will do our better to fit the bill.Inside the pursuit of strict quality-control and client thoughtful, our competent staff continuously keep consitently the interaction window readily available for the valued consumers.

Using an Electrode making machine is relatively simple, same with the nail production machine developed by FFI. Ab muscles first step be to ensure the machine is with in good working shape. This usually involves making sure that all of the equipment and that can be required set up and that the machine was properly lubricated. Once the machine try prepared, the operator should choose the insert material appropriate into the machine. The machine will then compress and mold the materials to create an Electrode.

Electrode making machines need periodic maintenance to ensure that they are in good working condition, along with FFI's product steel wire making machine. Manufacturers usually provide servicing guidelines that operators can follow to help keep the machine running well. Additionally, most manufacturers also provide repair services in case the machine develops any faults.

The quality of Electrodes produced using an Electrode making machine is usually high, same with the water tank wire drawing machine produced by FFI. It is because the machine was designed to uniform produce Electrodes in shape and size. Additionally, the machine allows for precise control over the manufacturing process, which helps to produce high-quality Electrodes.